Yield strength defines the maximum stress a material can withstand without permanent deformation, playing a crucial role in engineering and construction. Understanding your material's yield strength ensures safety and reliability under load-bearing conditions. Explore the rest of the article to learn how yield strength impacts material selection and design.

Table of Comparison

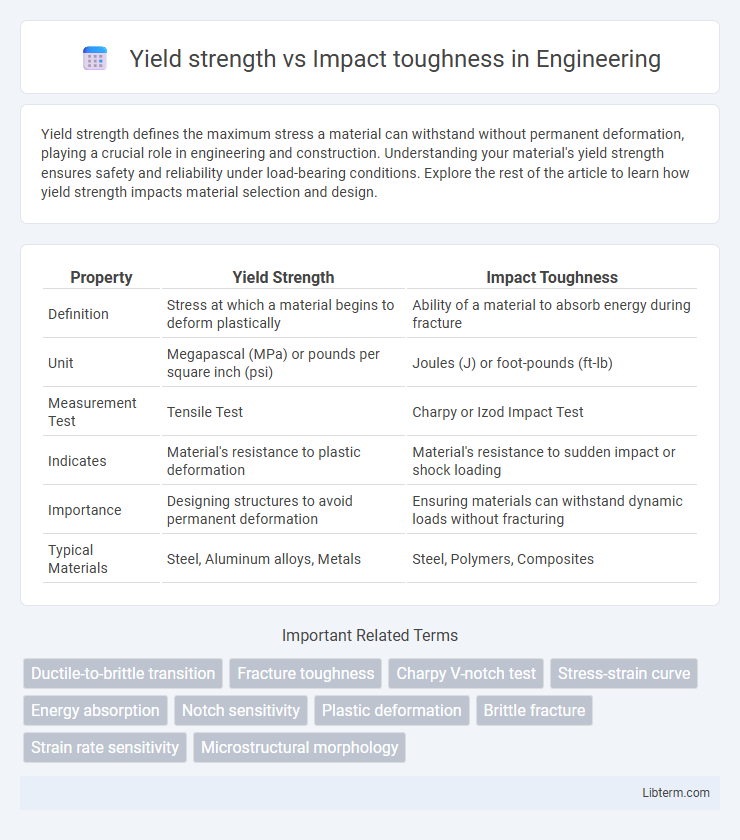

| Property | Yield Strength | Impact Toughness |

|---|---|---|

| Definition | Stress at which a material begins to deform plastically | Ability of a material to absorb energy during fracture |

| Unit | Megapascal (MPa) or pounds per square inch (psi) | Joules (J) or foot-pounds (ft-lb) |

| Measurement Test | Tensile Test | Charpy or Izod Impact Test |

| Indicates | Material's resistance to plastic deformation | Material's resistance to sudden impact or shock loading |

| Importance | Designing structures to avoid permanent deformation | Ensuring materials can withstand dynamic loads without fracturing |

| Typical Materials | Steel, Aluminum alloys, Metals | Steel, Polymers, Composites |

Introduction to Yield Strength and Impact Toughness

Yield strength measures a material's ability to withstand applied stress without permanent deformation, serving as a critical indicator of mechanical performance in structural applications. Impact toughness quantifies a material's capacity to absorb energy during rapid loading or sudden impacts, reflecting resistance to brittle fracture under dynamic conditions. Understanding the interplay between yield strength and impact toughness is essential for selecting materials that balance strength and ductility in engineering designs.

Defining Yield Strength: What It Means

Yield strength measures the maximum stress a material can withstand without permanent deformation, indicating its ability to maintain shape under load. Impact toughness quantifies a material's capacity to absorb energy and resist fracture under sudden, high-force impacts. Understanding yield strength helps engineers design components that remain structurally sound under operational stresses while balancing toughness to prevent brittle failure.

Understanding Impact Toughness

Impact toughness measures a material's ability to absorb energy and resist fracture under sudden or dynamic loading, which is crucial for applications involving shocks or impacts. Unlike yield strength, which quantifies the stress at which a material begins to deform plastically, impact toughness reflects the material's resistance to crack propagation and brittle failure. Understanding impact toughness involves analyzing factors such as temperature sensitivity, notch effects, and strain rate, all of which influence a material's performance in real-world impact scenarios.

Key Differences Between Yield Strength and Impact Toughness

Yield strength measures the maximum stress a material can endure without permanent deformation, indicating its ability to withstand static forces. Impact toughness evaluates a material's capacity to absorb energy during sudden, dynamic loads, reflecting resistance to fracture under impact conditions. Unlike yield strength, which is determined through tensile testing, impact toughness is assessed using methods like the Charpy or Izod impact tests, highlighting their distinct roles in material performance evaluation.

Factors Affecting Yield Strength

Yield strength is influenced by factors such as material composition, grain size, and heat treatment, which determine the resistance to permanent deformation under stress. Impact toughness is related to a material's ability to absorb energy during fracture, often affected by temperature and strain rate but is distinct from yield strength in mechanical properties. Understanding these factors helps optimize material selection for durability and structural integrity in engineering applications.

Variables Influencing Impact Toughness

Impact toughness depends on factors such as temperature, strain rate, and material microstructure, all of which influence a material's ability to absorb energy during fracture. Grain size, alloy composition, and heat treatment significantly affect impact toughness by altering crack propagation resistance and ductility. Yield strength primarily measures elastic limit, while impact toughness quantifies energy absorption capacity, making their relationship highly dependent on these controlling variables.

Material Selection: Yield Strength vs. Impact Toughness

Yield strength and impact toughness represent critical mechanical properties influencing material selection for engineering applications. Yield strength measures a material's ability to withstand permanent deformation under stress, essential for structural stability, while impact toughness quantifies resistance to sudden, high-energy impacts, crucial for safety and durability under dynamic loading. Balancing these properties ensures optimal performance, where materials with high yield strength and adequate impact toughness prevent failure in both static and impact conditions.

Testing Methods for Yield Strength and Impact Toughness

Yield strength is primarily tested using tensile testing machines that apply uniaxial force to measure the stress at which a material begins to deform plastically. Impact toughness is evaluated through Charpy or Izod impact tests, where a pendulum strikes a notched specimen to measure energy absorbed during fracture. Both testing methods provide critical data for assessing material performance under different stress conditions, relevant in engineering design and safety analysis.

Real-World Applications and Case Studies

Yield strength determines a material's ability to withstand applied stress without permanent deformation, crucial in structural applications like bridges and buildings where load-bearing capacity is essential. Impact toughness measures resistance to sudden shocks or impacts, critical in automotive and aerospace industries to prevent catastrophic failure during collisions or adverse conditions. Case studies in pipeline engineering demonstrate materials with balanced yield strength and impact toughness ensuring safety under pressure and temperature fluctuations, highlighting the trade-offs necessary for real-world durability and performance.

Balancing Yield Strength and Impact Toughness in Engineering

Balancing yield strength and impact toughness is critical in engineering to ensure materials can withstand high stress without permanent deformation while absorbing energy from sudden impacts. High yield strength often correlates with increased hardness but can reduce impact toughness, making materials more brittle and prone to fracture under dynamic loading. Engineering applications demand optimized alloys and heat treatments that enhance both properties, achieving reliable structural integrity and durability in challenging operational environments.

Yield strength Infographic

libterm.com

libterm.com