Forging is a manufacturing process that shapes metal using compressive forces, enhancing the material's strength and structural integrity. This technique is widely used to produce high-performance components for industries such as aerospace, automotive, and construction. Explore how forging can improve your products and understand its various methods by reading the rest of the article.

Table of Comparison

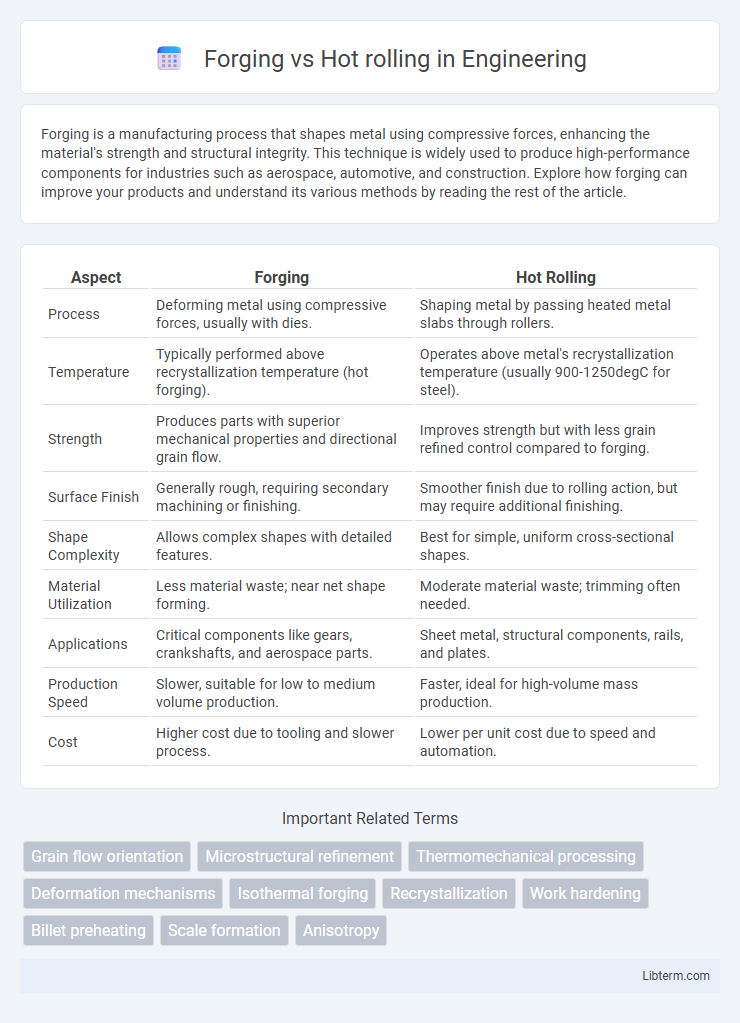

| Aspect | Forging | Hot Rolling |

|---|---|---|

| Process | Deforming metal using compressive forces, usually with dies. | Shaping metal by passing heated metal slabs through rollers. |

| Temperature | Typically performed above recrystallization temperature (hot forging). | Operates above metal's recrystallization temperature (usually 900-1250degC for steel). |

| Strength | Produces parts with superior mechanical properties and directional grain flow. | Improves strength but with less grain refined control compared to forging. |

| Surface Finish | Generally rough, requiring secondary machining or finishing. | Smoother finish due to rolling action, but may require additional finishing. |

| Shape Complexity | Allows complex shapes with detailed features. | Best for simple, uniform cross-sectional shapes. |

| Material Utilization | Less material waste; near net shape forming. | Moderate material waste; trimming often needed. |

| Applications | Critical components like gears, crankshafts, and aerospace parts. | Sheet metal, structural components, rails, and plates. |

| Production Speed | Slower, suitable for low to medium volume production. | Faster, ideal for high-volume mass production. |

| Cost | Higher cost due to tooling and slower process. | Lower per unit cost due to speed and automation. |

Introduction to Forging and Hot Rolling

Forging is a metalworking process involving the shaping of metal using localized compressive forces, typically delivered by a hammer or a die, to enhance mechanical properties such as strength and toughness. Hot rolling, on the other hand, involves passing heated metal stock through rollers to reduce thickness and improve surface finish while maintaining flexibility and ductility. Both processes are essential in manufacturing industries, with forging offering superior grain structure refinement and hot rolling enabling efficient large-scale production of uniform metal sheets and components.

Key Differences Between Forging and Hot Rolling

Forging involves deforming metal using compressive forces, typically with hammers or presses, resulting in improved grain structure and mechanical properties, while hot rolling passes heated metal through rollers to reduce thickness and create uniform cross-sections with less impact on grain refinement. Forging produces components with superior strength and fatigue resistance due to directional grain flow, whereas hot rolling is more efficient for shaping large volumes of metal with consistent thickness and surface finish. The key differences lie in process mechanics, material properties enhancement, and typical applications such as high-performance parts for forging and sheet or plate production for hot rolling.

Overview of the Forging Process

Forging is a manufacturing process involving the shaping of metal using localized compressive forces, typically delivered by a hammer or press, which refines the grain structure and enhances mechanical properties. Unlike hot rolling, which deforms metal between rollers to create uniform thickness, forging allows for greater control over the final shape and targeted strengthening of critical areas. This process is essential for producing high-strength components in aerospace, automotive, and industrial applications.

Overview of the Hot Rolling Process

The hot rolling process involves heating metal above its recrystallization temperature and then passing it through rollers to achieve the desired thickness and shape, enhancing ductility and reducing internal stresses. This process is widely used for producing large quantities of sheet metal, plates, and structural shapes with improved mechanical properties. Hot rolling differs from forging by offering continuous deformation with less labor intensity and more uniform thickness.

Material Properties: Forging vs Hot Rolling

Forging enhances material properties by producing a dense, refined grain structure that improves strength, toughness, and fatigue resistance compared to hot rolling. Hot rolling, while effective for shaping metals at elevated temperatures, often results in a coarser grain structure and less directional grain flow, which can reduce mechanical performance. Forged components typically exhibit superior mechanical properties and reliability due to the controlled deformation and microstructural alignment inherent in the forging process.

Applications of Forged Components vs Hot Rolled Components

Forged components are widely used in aerospace, automotive, and heavy machinery industries due to their superior strength, toughness, and fatigue resistance, making them ideal for critical parts like gears, crankshafts, and turbine discs. Hot-rolled components find application in construction, structural beams, and pipelines, where dimensional accuracy and uniformity at lower cost are prioritized over the enhanced mechanical properties of forgings. The choice between forged and hot-rolled components depends on the specific performance requirements and service conditions of the end-use application.

Advantages of Forging Over Hot Rolling

Forging produces components with superior mechanical properties, such as increased tensile strength and fatigue resistance, due to the refined grain structure achieved during the process. The controlled deformation in forging reduces the likelihood of defects like porosity and segregation, resulting in more reliable and uniform parts. Forged products also exhibit enhanced dimensional accuracy and surface finish compared to hot rolled materials, which require extensive machining and finishing.

Advantages of Hot Rolling Over Forging

Hot rolling offers superior efficiency in producing large volume metal products with consistent dimensional accuracy, reducing overall manufacturing time compared to forging. The process enhances material ductility and surface finish, enabling easier shaping of complex geometries while minimizing defects like cracks or scale. Cost-effectiveness and improved mechanical properties such as grain refinement and uniformity make hot rolling preferable in industries like automotive and construction.

Cost Comparison: Forging vs Hot Rolling

Forging typically incurs higher production costs due to greater energy consumption and slower processing times compared to hot rolling, which benefits from continuous operation and lower energy use. While forging offers superior mechanical properties and material strength, its higher tooling and labor expenses increase overall costs. Hot rolling, favored for producing large volumes with relatively lower costs, is more economical in applications prioritizing dimensional accuracy over enhanced strength.

Choosing the Right Process for Your Application

Forging offers superior strength and structural integrity due to its closed-die process, making it ideal for high-stress applications like aerospace and automotive components. Hot rolling provides excellent dimensional accuracy and surface finish, suited for large-scale production of uniform sheets and structural sections. Selecting between forging and hot rolling depends on factors such as required mechanical properties, component complexity, and production volume to optimize performance and cost-efficiency.

Forging Infographic

libterm.com

libterm.com