Magnetic bearings use magnetic fields to support rotating shafts without physical contact, reducing friction and wear while improving efficiency and lifespan. Advanced sensors and control systems maintain precise shaft positioning, making them ideal for high-speed and sensitive applications. Discover how magnetic bearings can revolutionize your machinery by reading the full article.

Table of Comparison

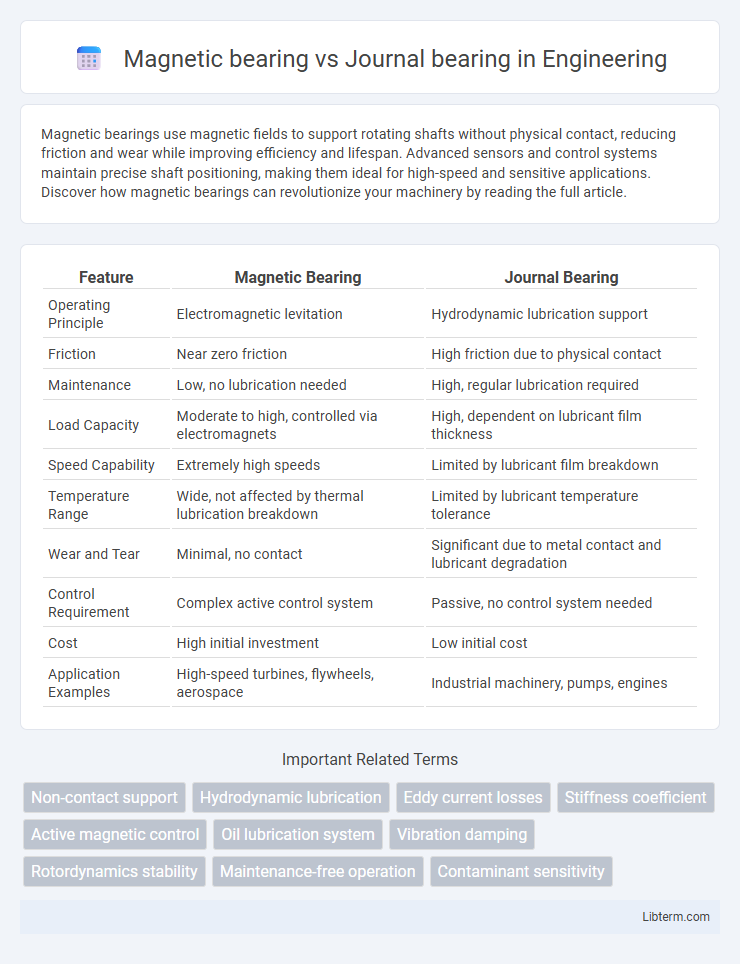

| Feature | Magnetic Bearing | Journal Bearing |

|---|---|---|

| Operating Principle | Electromagnetic levitation | Hydrodynamic lubrication support |

| Friction | Near zero friction | High friction due to physical contact |

| Maintenance | Low, no lubrication needed | High, regular lubrication required |

| Load Capacity | Moderate to high, controlled via electromagnets | High, dependent on lubricant film thickness |

| Speed Capability | Extremely high speeds | Limited by lubricant film breakdown |

| Temperature Range | Wide, not affected by thermal lubrication breakdown | Limited by lubricant temperature tolerance |

| Wear and Tear | Minimal, no contact | Significant due to metal contact and lubricant degradation |

| Control Requirement | Complex active control system | Passive, no control system needed |

| Cost | High initial investment | Low initial cost |

| Application Examples | High-speed turbines, flywheels, aerospace | Industrial machinery, pumps, engines |

Introduction to Magnetic and Journal Bearings

Magnetic bearings use electromagnetic fields to support and stabilize rotating shafts without physical contact, reducing friction and wear compared to traditional bearings. Journal bearings rely on a thin film of lubricant between the bearing surface and the rotating shaft to provide a load-carrying mechanism, commonly used in heavy machinery due to their simplicity and cost-effectiveness. Magnetic bearings offer higher precision and lower maintenance, while journal bearings remain prevalent in applications with high load capacities and lower speeds.

Fundamental Principles of Magnetic Bearings

Magnetic bearings operate by suspending a rotating shaft using electromagnetic forces, eliminating physical contact and thus reducing friction and wear, unlike journal bearings which rely on a thin lubricating film between the shaft and bearing surface. These bearings use active control systems with sensors and electromagnets to precisely position the shaft in real-time, ensuring stability and load support. The fundamental principle of magnetic bearings is based on controlled magnetic flux density and electromagnetic force generation, enabling non-contact rotation and high-speed operation with minimal maintenance.

Overview of Journal Bearing Technology

Journal bearing technology utilizes a lubricated sleeve to support rotating shafts, reducing friction through a thin film of oil between the shaft and bearing surface. This technology relies on hydrodynamic lubrication principles to maintain a stable oil film that prevents metal-to-metal contact, thereby enhancing durability and load capacity. Common in heavy machinery and automotive engines, journal bearings offer a cost-effective and proven solution, though they require regular maintenance due to wear and lubrication dependency.

Key Differences Between Magnetic and Journal Bearings

Magnetic bearings use electromagnetic forces to levitate and support the rotor without physical contact, enabling near-frictionless operation and reduced wear, while journal bearings rely on a thin film of lubricating fluid between the rotating shaft and bearing surface. Magnetic bearings provide precise rotor control and can operate at higher speeds with lower maintenance, whereas journal bearings depend on hydrodynamic lubrication and are more susceptible to wear and friction. Key differences include load capacity, operational speed limits, maintenance requirements, and sensitivity to contamination, with magnetic bearings excelling in advanced, high-speed applications and journal bearings favored for cost-effective, traditional machinery.

Performance Comparison: Efficiency and Speed

Magnetic bearings offer superior efficiency and higher operational speeds compared to journal bearings due to their non-contact, frictionless design, which eliminates lubrication losses and wear. Journal bearings rely on a fluid film for load support, causing energy losses from viscous friction and limiting maximum rotational speeds. Consequently, magnetic bearings achieve enhanced performance in high-speed applications with reduced maintenance and improved reliability.

Maintenance Requirements and Lifecycle

Magnetic bearings require minimal maintenance due to their non-contact operation, resulting in reduced wear and extended lifecycle compared to journal bearings, which experience mechanical friction and need regular lubrication and inspection. Journal bearings demand frequent maintenance to monitor oil condition, alignment, and surface wear, often leading to higher downtime and shorter overall lifespan. The superior durability and low maintenance profile of magnetic bearings make them ideal for applications requiring long-term reliability and reduced operational costs.

Applications and Industry Use Cases

Magnetic bearings excel in high-speed machinery applications such as turbomachinery, flywheels, and vacuum pumps due to their contact-free operation, which minimizes wear and maintenance. Journal bearings are commonly used in heavy machinery like turbines, compressors, and automotive engines, providing reliable support for rotating shafts under varying loads with cost-effective design. Industries including aerospace, power generation, and manufacturing leverage magnetic bearings for precision and efficiency, while journal bearings dominate in automotive, marine, and industrial equipment due to their robustness and simplicity.

Cost Analysis: Initial Investment and Operation

Magnetic bearings have a higher initial investment cost compared to journal bearings due to their advanced technology and precision manufacturing requirements. Operating costs for magnetic bearings are generally lower, benefiting from reduced friction, minimal wear, and decreased maintenance needs, whereas journal bearings incur higher expenses related to lubrication, wear parts replacement, and frequent servicing. The total cost of ownership favors magnetic bearings in high-performance or critical applications despite the upfront expense, while journal bearings remain cost-effective for simpler, low-demand environments.

Environmental Impact and Sustainability

Magnetic bearings reduce environmental impact by eliminating the need for lubricating oils, thus preventing oil leakage and contamination commonly associated with journal bearings. Their energy efficiency is higher due to reduced friction, leading to lower greenhouse gas emissions over operational lifespan. Journal bearings rely on lubricants that generate waste and require disposal, making magnetic bearings a more sustainable choice in industrial applications.

Future Trends in Bearing Technologies

Magnetic bearings, leveraging electromagnetic suspension for frictionless operation, are poised to revolutionize industries requiring high-speed, low-maintenance machinery, outperforming traditional journal bearings found in various heavy-duty applications. Future trends indicate a shift towards smart magnetic bearing systems integrated with IoT sensors and AI-driven predictive maintenance to enhance operational efficiency and reliability. Advances in materials science and control algorithms are expected to further reduce energy consumption and increase the lifespan of bearings in aerospace, renewable energy, and advanced manufacturing sectors.

Magnetic bearing Infographic

libterm.com

libterm.com