Strength is essential for improving physical performance, increasing endurance, and preventing injuries. Building muscle mass and enhancing your overall power contribute to a healthier, more resilient body. Explore the rest of this article to discover effective strength-building techniques tailored to your needs.

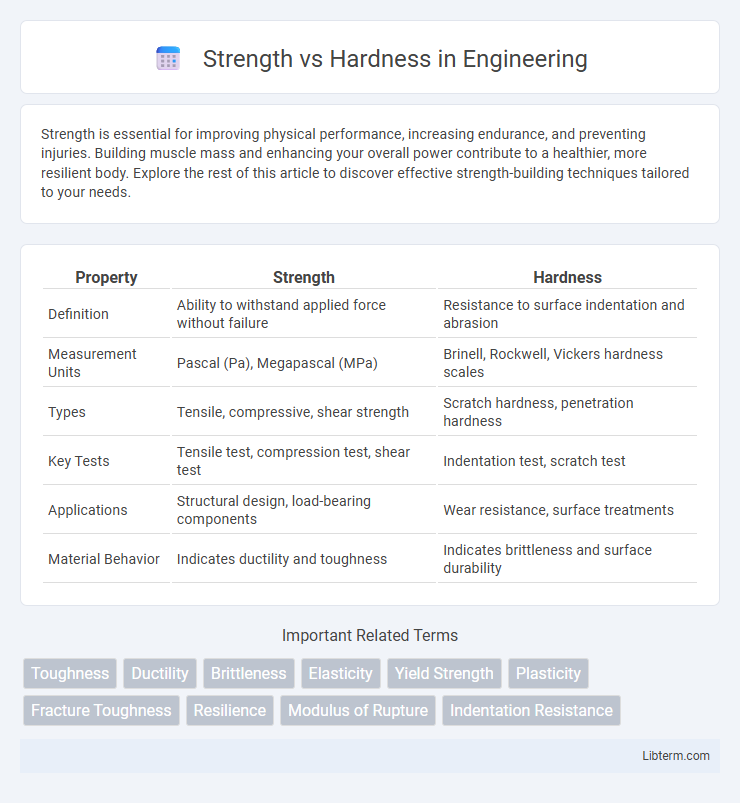

Table of Comparison

| Property | Strength | Hardness |

|---|---|---|

| Definition | Ability to withstand applied force without failure | Resistance to surface indentation and abrasion |

| Measurement Units | Pascal (Pa), Megapascal (MPa) | Brinell, Rockwell, Vickers hardness scales |

| Types | Tensile, compressive, shear strength | Scratch hardness, penetration hardness |

| Key Tests | Tensile test, compression test, shear test | Indentation test, scratch test |

| Applications | Structural design, load-bearing components | Wear resistance, surface treatments |

| Material Behavior | Indicates ductility and toughness | Indicates brittleness and surface durability |

Understanding Strength and Hardness: Key Definitions

Strength refers to a material's ability to withstand applied forces without failure, typically measured by tensile, compressive, or shear strength. Hardness indicates a material's resistance to surface deformation or indentation, often quantified using tests like Brinell, Rockwell, or Vickers hardness scales. Understanding the distinction between strength and hardness is crucial for selecting materials suitable for structural applications versus wear-resistant components.

The Science Behind Material Strength

Material strength measures a material's ability to withstand applied stress without failure, encompassing tensile, compressive, and shear strength types crucial for structural applications. Hardness indicates a material's resistance to localized plastic deformation, often assessed by indentation tests like the Mohs scale, Rockwell, or Vickers hardness tests. Understanding the science behind material strength involves analyzing atomic bonding, microstructure, and dislocation movement, which determine how materials deform under load.

How Hardness Is Measured in Materials

Hardness in materials is measured using standardized tests such as the Mohs scale, Brinell hardness test, Rockwell hardness test, and Vickers hardness test, each quantifying resistance to deformation or indentation. The Mohs scale ranks materials based on scratch resistance from 1 (talc) to 10 (diamond), while Brinell, Rockwell, and Vickers tests measure hardness through indentation size or depth under a specific load with different indenter types. These methods provide essential data for selecting materials in engineering applications, balancing hardness with other mechanical properties like tensile strength and toughness.

Types of Strength: Tensile, Compressive, and Shear

Tensile strength measures a material's ability to withstand pulling forces without breaking, crucial in cables and structural beams. Compressive strength evaluates resistance to crushing forces, essential in concrete and masonry to prevent deformation or failure. Shear strength defines the capacity to resist sliding forces between layers, vital for bolts and rivets to maintain joint integrity under load.

Comparing Hardness Scales: Mohs, Rockwell, and Brinell

Hardness scales such as Mohs, Rockwell, and Brinell differ significantly in their measurement methods and applications. The Mohs scale ranks materials based on scratch resistance from 1 (talc) to 10 (diamond), making it suitable for mineral identification but less precise for engineering. Rockwell and Brinell scales quantify hardness through indentation, with Rockwell measuring depth under load for metals and alloys, and Brinell using a steel ball indentation to assess strength and resistance in heterogeneous materials.

Relationship Between Strength and Hardness

Strength and hardness are correlated mechanical properties that describe different aspects of a material's resistance to deformation. Strength measures a material's ability to withstand applied stress without failure, while hardness quantifies its resistance to localized plastic deformation or indentation. Typically, materials with higher hardness exhibit greater strength, reflecting the intrinsic atomic bonding and microstructure that control both properties.

Real-World Applications Requiring High Strength

High strength materials, such as steel alloys and titanium, are essential in construction and aerospace industries where structural integrity under heavy loads is critical. These materials resist deformation, ensuring safety and durability in bridges, aircraft frames, and heavy machinery. While hardness measures resistance to surface indentation, strength specifically addresses the ability to withstand applied forces without failure in demanding real-world applications.

Industries Relying on Superior Hardness

Industries such as aerospace, automotive, and tooling rely heavily on materials with superior hardness to ensure durability and wear resistance in demanding applications. Hardness is critical for cutting tools, molds, and engine components that endure high friction and stress, preventing deformation and extending service life. While strength measures the ability to withstand force without breaking, hardness specifically addresses resistance to surface indentation and abrasion, making it invaluable for industrial performance and longevity.

Common Misconceptions: Strength vs Hardness

Strength and hardness are often confused but measure different material properties: strength refers to a material's ability to withstand an applied force without failure, while hardness indicates resistance to surface deformation or scratching. Many assume a harder material is always stronger, yet materials like glass are hard but brittle with low tensile strength. Understanding this distinction is crucial in selecting materials for applications requiring durability versus wear resistance.

Selecting Materials: Balancing Strength and Hardness

Selecting materials requires balancing tensile strength, the ability to withstand forces without breaking, and hardness, the resistance to surface deformation or scratches. Metals such as steel offer high strength for structural applications, while ceramics provide superior hardness ideal for wear-resistant components. Understanding the trade-offs between strength and hardness enables engineers to optimize material performance for specific uses like cutting tools, automotive parts, or protective coatings.

Strength Infographic

libterm.com

libterm.com