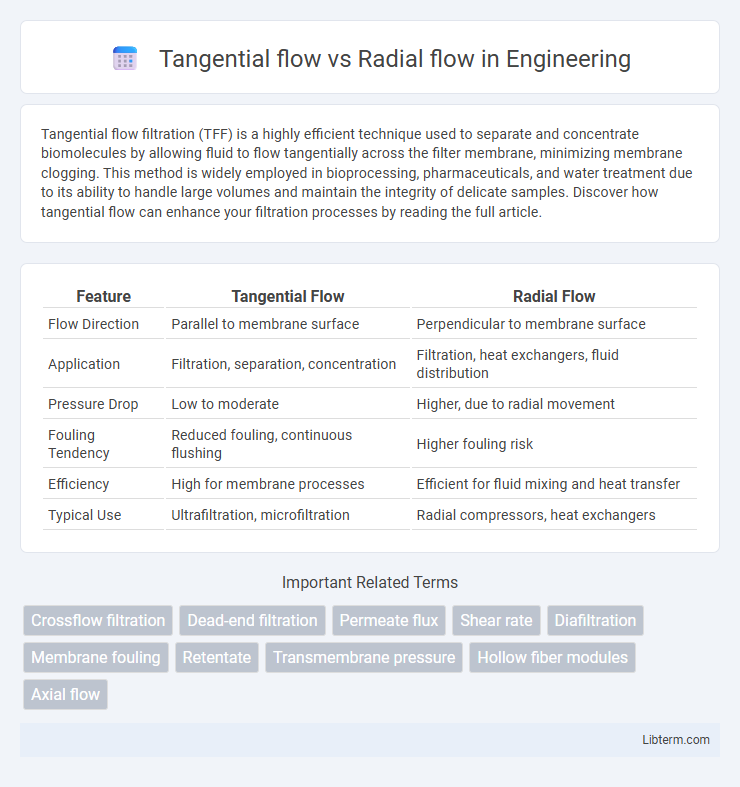

Tangential flow filtration (TFF) is a highly efficient technique used to separate and concentrate biomolecules by allowing fluid to flow tangentially across the filter membrane, minimizing membrane clogging. This method is widely employed in bioprocessing, pharmaceuticals, and water treatment due to its ability to handle large volumes and maintain the integrity of delicate samples. Discover how tangential flow can enhance your filtration processes by reading the full article.

Table of Comparison

| Feature | Tangential Flow | Radial Flow |

|---|---|---|

| Flow Direction | Parallel to membrane surface | Perpendicular to membrane surface |

| Application | Filtration, separation, concentration | Filtration, heat exchangers, fluid distribution |

| Pressure Drop | Low to moderate | Higher, due to radial movement |

| Fouling Tendency | Reduced fouling, continuous flushing | Higher fouling risk |

| Efficiency | High for membrane processes | Efficient for fluid mixing and heat transfer |

| Typical Use | Ultrafiltration, microfiltration | Radial compressors, heat exchangers |

Introduction to Filtration Methods

Tangential flow filtration (TFF) utilizes a cross-flow mechanism where the feed stream moves tangentially across the filter membrane, reducing membrane fouling and enabling efficient separation of particles based on size. Radial flow filtration, in contrast, directs the feed flow radially through a cylindrical membrane surface, optimizing filtration area and providing high throughput suitable for large volume processing. Both methods are critical in bioprocessing and water treatment, with the choice dependent on factors like fouling propensity, filtration speed, and product recovery requirements.

Overview of Tangential Flow Filtration (TFF)

Tangential Flow Filtration (TFF) operates by directing fluid parallel to the filter membrane, reducing clogging and allowing continuous processing of large sample volumes. This method enhances the efficiency of separation and concentration in bioprocessing applications such as protein purification and cell harvesting. TFF offers scalability and consistent membrane performance compared to Radial Flow filtration, which directs fluid perpendicular, often resulting in faster fouling.

Overview of Radial Flow Filtration (RFF)

Radial Flow Filtration (RFF) utilizes a cylindrical membrane design that directs fluid flow radially from the inside to the outside or vice versa, optimizing filtration efficiency for high solids content and large volumes. This configuration minimizes membrane fouling and pressure drop, enhancing throughput and recovery rates compared to Tangential Flow Filtration (TFF), which directs fluid tangentially across the membrane surface. RFF is particularly effective in industrial applications requiring robust separation and concentration processes, such as wastewater treatment and food processing.

Core Principles: TFF vs RFF

Tangential flow filtration (TFF) operates by directing fluid parallel to the filter membrane, reducing fouling and allowing continuous processing of biomolecules, whereas radial flow filtration (RFF) pushes fluid perpendicular to the membrane, enhancing filtration capacity and reducing pressure drops. TFF's core principle emphasizes shear force to minimize cake formation, ideal for sensitive biomolecule separation, while RFF focuses on maximizing membrane surface area utilization for high-volume applications. These fundamental differences impact efficiency, scalability, and application suitability in bioprocessing and filtration systems.

Key Applications in Bioprocessing

Tangential flow filtration (TFF) is primarily applied in biomolecule concentration, buffer exchange, and cell harvesting in bioprocessing due to its efficiency in handling large volumes and minimizing membrane fouling. Radial flow filtration, commonly used in bioreactors for cell culture clarification and sterile filtration, offers higher flow rates and reduced pressure drop, making it suitable for continuous processing. Both methods play critical roles in downstream purification and microbial removal, ensuring product purity and process scalability in biopharmaceutical manufacturing.

Performance and Efficiency Comparison

Tangential flow filtration (TFF) offers higher performance in processing fluids by enabling continuous filtration with minimal fouling, resulting in better membrane longevity and improved flux rates compared to radial flow systems. Radial flow filtration typically exhibits lower energy efficiency due to higher pressure drops and increased likelihood of clogging, reducing overall throughput. The inherent design of TFF maximizes surface area utilization and reduces maintenance downtime, driving superior efficiency in bioprocessing and industrial filtration applications.

Advantages and Limitations of Tangential Flow

Tangential flow filtration (TFF) offers advantages such as higher filtration efficiency, reduced membrane fouling, and the ability to process larger volumes with continuous operation, making it ideal for protein concentration and cell harvesting. Limitations include higher equipment costs, complex setup requirements, and potential shear stress that can damage delicate biomolecules or cells. Compared to radial flow, TFF provides better control over filtration parameters but may require more frequent membrane maintenance due to the tangential flow dynamics.

Advantages and Limitations of Radial Flow

Radial flow systems offer advantages such as enhanced flow distribution and lower pressure drop, making them ideal for processes requiring uniform filtration and high throughput. Their design allows for effective handling of viscous fluids and solids, reducing clogging and maintenance needs. Limitations include higher initial costs and complexity in scale-up compared to tangential flow systems, which may restrict their use in smaller-scale or budget-sensitive applications.

Selection Criteria: When to Choose TFF or RFF

Tangential Flow Filtration (TFF) is ideal for applications requiring efficient separation of large volumes with low fouling, often used in protein concentration or diafiltration processes. Radial Flow Filtration (RFF) suits scenarios involving high solid content or particulates, providing robust handling of viscous or slurry samples with reduced clogging risk. Selecting TFF or RFF depends on factors like feed composition, fouling propensity, desired flow rate, and process scale, ensuring optimal filtration performance and membrane longevity.

Future Trends in Filtration Technology

Tangential flow filtration (TFF) advances focus on enhancing membrane permeability and fouling resistance through novel materials like graphene and nanocomposites, optimizing applications in biopharmaceutical and water treatment sectors. Radial flow filtration trends emphasize modular, scalable designs with improved energy efficiency and real-time monitoring capabilities powered by AI, aiming to meet increasing industrial demands for sustainability and process automation. Integration of smart sensors and AI-driven process control in both TFF and radial flow systems is revolutionizing filtration by maximizing throughput, reducing downtime, and enabling predictive maintenance.

Tangential flow Infographic

libterm.com

libterm.com