Proportional control is a common feedback mechanism in control systems where the output is adjusted proportionally to the error signal, helping maintain system stability and accuracy. This method allows your system to quickly correct deviations by applying a control effort directly related to the difference between the desired setpoint and the actual value. Explore the rest of this article to understand how proportional control can optimize your system's performance and its practical applications.

Table of Comparison

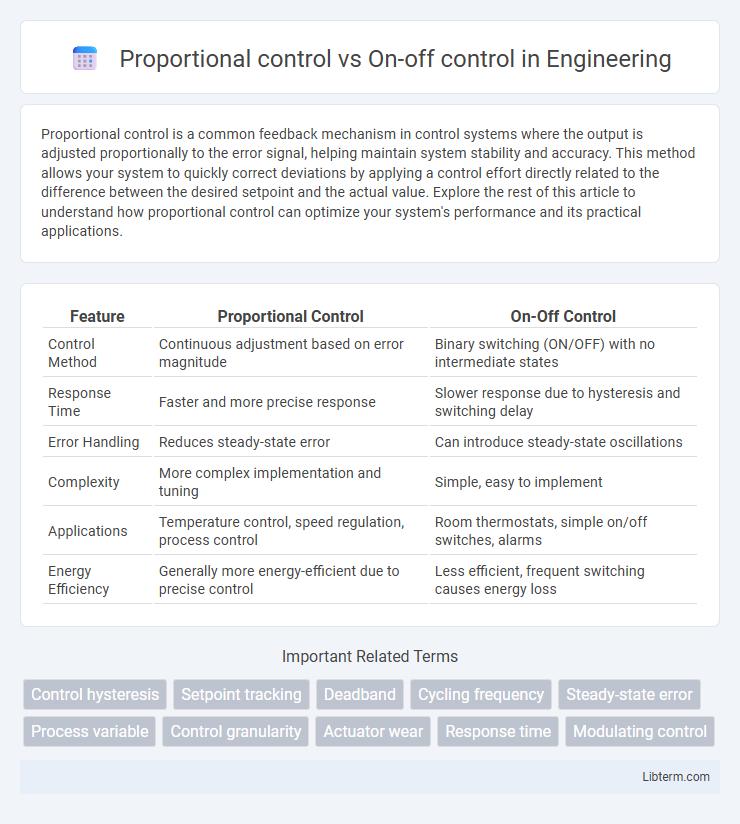

| Feature | Proportional Control | On-Off Control |

|---|---|---|

| Control Method | Continuous adjustment based on error magnitude | Binary switching (ON/OFF) with no intermediate states |

| Response Time | Faster and more precise response | Slower response due to hysteresis and switching delay |

| Error Handling | Reduces steady-state error | Can introduce steady-state oscillations |

| Complexity | More complex implementation and tuning | Simple, easy to implement |

| Applications | Temperature control, speed regulation, process control | Room thermostats, simple on/off switches, alarms |

| Energy Efficiency | Generally more energy-efficient due to precise control | Less efficient, frequent switching causes energy loss |

Introduction to Proportional and On-Off Control

Proportional control continuously adjusts the output in direct proportion to the error signal, providing precise modulation for process variables like temperature or pressure. On-off control operates by switching the output fully on or off when the process variable deviates from the setpoint, resulting in simpler but often less stable control. Both methods are fundamental in automation systems, with proportional control offering smoother regulation and on-off control favored for basic, cost-effective applications.

Fundamental Concepts of Control Systems

Proportional control adjusts the output proportionally to the error magnitude, providing smoother system responses and reducing steady-state errors in control systems. On-off control switches the output fully on or off based on a threshold, leading to simpler design but causing oscillations or hunting around the setpoint. Understanding these fundamental concepts helps in selecting appropriate control strategies for stability and precision in industrial automation.

How Proportional Control Works

Proportional control works by continuously adjusting the output signal in direct proportion to the error, which is the difference between the desired setpoint and the actual process variable. The controller calculates the output using a proportional gain factor multiplied by the error magnitude, enabling smoother and more precise control compared to on-off control. This method reduces oscillations and steady-state errors by providing variable control action rather than binary outputs.

Mechanics of On-Off Control

On-Off control operates by switching the output fully on or off based on a set threshold, creating a binary state that is simple and cost-effective but can cause oscillations around the setpoint. The mechanism relies on feedback from a sensor to determine whether the controlled variable exceeds or falls below the setpoint, triggering the actuator to either activate or deactivate. This control type is common in thermostats and basic mechanical systems where precision is less critical, and the rapid switching provides straightforward regulation without continuous modulation.

Key Differences Between Proportional and On-Off Control

Proportional control continuously adjusts the output signal in direct proportion to the error, providing smoother and more precise control over system variables, whereas on-off control operates in a binary manner, switching fully on or off based on setpoint thresholds. Proportional control minimizes steady-state error and reduces system oscillations, while on-off control can cause frequent cycling and increased wear due to abrupt switching. The main difference lies in the response style: proportional control offers variable output for fine-tuned regulation, whereas on-off control delivers simple, discrete control actions.

Advantages of Proportional Control

Proportional control offers enhanced accuracy by continuously adjusting the control output in direct proportion to the error, reducing steady-state error and preventing system oscillations common in on-off control. It improves system stability and responsiveness, enabling finer tuning for processes requiring precise regulation, such as temperature or pressure control. This results in smoother operation, energy efficiency, and extended equipment lifespan compared to the binary nature of on-off control.

Benefits and Drawbacks of On-Off Control

On-off control offers simplicity and easy implementation, making it cost-effective for basic temperature or pressure regulation systems. However, it can cause frequent cycling and overshoot due to its binary nature, leading to increased wear on mechanical components and less precise control. This method is less suitable for processes requiring fine-tuned adjustments, where proportional control provides smoother and more stable operation.

Typical Applications for Each Control Type

Proportional control is commonly used in temperature regulation systems, such as HVAC units and industrial heating processes, where maintaining a precise and stable setpoint is critical. On-off control finds typical applications in simple devices like household thermostats, refrigerator compressors, and basic irrigation systems, where the control output toggles fully on or off to manage the process with minimal complexity. Proportional control offers finer adjustments suitable for chemical processes and motor speed control, while on-off control is favored for systems with binary operational states or where cost-efficiency is paramount.

Factors to Consider When Choosing a Control Method

Factors to consider when choosing between proportional control and on-off control include system precision requirements, response speed, and complexity tolerance. Proportional control offers finer adjustment and reduced oscillations, making it ideal for processes demanding tight regulation, whereas on-off control is simpler and cost-effective for systems with less critical accuracy needs. Process dynamics, sensor resolution, and maintenance costs also influence the optimal control strategy selection.

Conclusion: Which Control Strategy Suits Your Needs?

Proportional control offers precise regulation by continuously adjusting output based on error magnitude, ideal for applications requiring smooth and stable performance. On-off control, with its simple binary output, suits systems where cost-effectiveness and straightforward operation outweigh the need for fine control. Selecting a control strategy depends on factors like system complexity, accuracy requirements, and budget constraints to ensure optimal performance and efficiency.

Proportional control Infographic

libterm.com

libterm.com