Bending is a fundamental mechanical process that involves deforming a material by applying force, causing it to curve without breaking. This technique is widely used in manufacturing, construction, and engineering to shape metals, plastics, and other materials into desired forms. Explore the rest of the article to understand the types, applications, and best practices of bending in various industries.

Table of Comparison

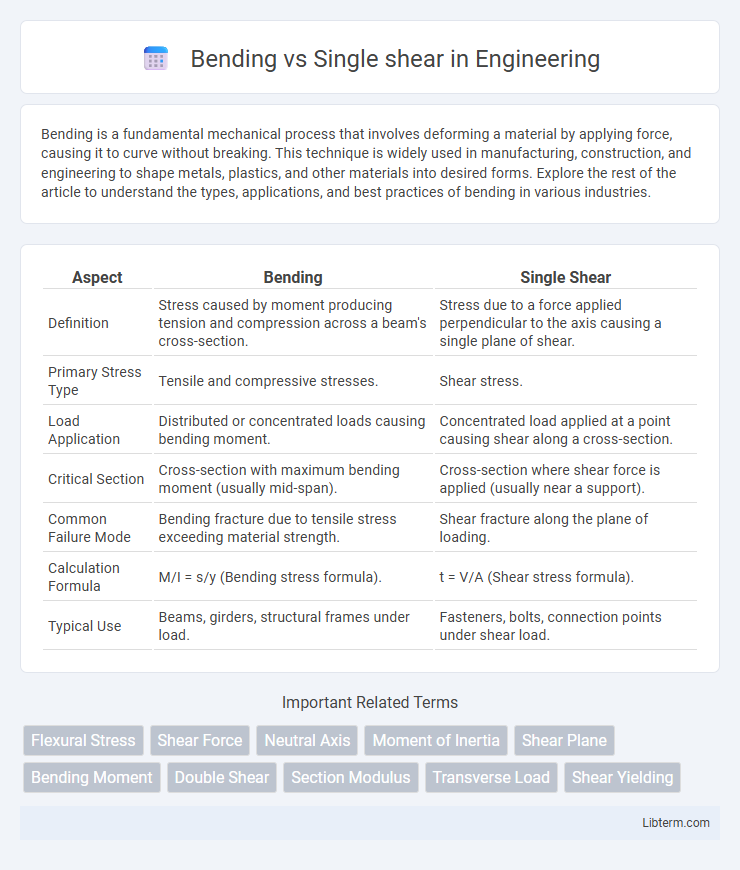

| Aspect | Bending | Single Shear |

|---|---|---|

| Definition | Stress caused by moment producing tension and compression across a beam's cross-section. | Stress due to a force applied perpendicular to the axis causing a single plane of shear. |

| Primary Stress Type | Tensile and compressive stresses. | Shear stress. |

| Load Application | Distributed or concentrated loads causing bending moment. | Concentrated load applied at a point causing shear along a cross-section. |

| Critical Section | Cross-section with maximum bending moment (usually mid-span). | Cross-section where shear force is applied (usually near a support). |

| Common Failure Mode | Bending fracture due to tensile stress exceeding material strength. | Shear fracture along the plane of loading. |

| Calculation Formula | M/I = s/y (Bending stress formula). | t = V/A (Shear stress formula). |

| Typical Use | Beams, girders, structural frames under load. | Fasteners, bolts, connection points under shear load. |

Introduction to Bending and Single Shear

Bending occurs when a structural element is subjected to a moment or transverse load causing it to curve, generating tension and compression stresses across its cross-section. Single shear involves a force applied parallel to a surface, creating a shear stress that tends to cause one part of the material to slide past the adjacent part along a single plane. Understanding the differences between bending and single shear is crucial for designing safe and efficient structural components under various loading conditions.

Definitions and Fundamental Concepts

Bending refers to the deformation of a structural element when an external moment or load creates tension on one side and compression on the other, causing the element to curve. Single shear occurs when a force causes a material, such as a bolt or rivet, to experience shear stress across one plane, typically where two components are joined. Understanding the difference between bending and single shear is crucial for accurate stress analysis and effective structural design.

Key Differences Between Bending and Single Shear

Bending involves a material experiencing a moment force causing it to curve or deflect, while single shear refers to a force applied parallel to the surface that causes a material to fail along a single plane. The key difference lies in stress distribution: bending induces tensile and compressive stresses across the cross-section, whereas single shear produces shear stress concentrated at the shear plane. Engineering applications assess bending for beam deflection and single shear for fastener failure analysis, emphasizing different failure modes and stress types.

Real-world Applications of Bending

Bending is commonly used in structural beams, bridges, and cantilevered components where load distribution and rigidity are critical, allowing materials to withstand moments without failure. Real-world applications include automotive frames, aircraft wings, and building floors, where bending stresses dominate and must be precisely calculated to ensure safety and durability. Single shear, often seen in mechanical joints like rivets and bolts, mainly resists forces parallel to the fastened sections but does not accommodate the complex stress distributions present in bending scenarios.

Real-world Applications of Single Shear

Single shear occurs when a force is applied perpendicular to a fastener or structural component, causing it to experience shear stress along a single plane, commonly seen in bolted or riveted joints in machinery and structural frameworks. Real-world applications of single shear include connecting beams to columns in steel structures, where bolts transfer loads while allowing slight rotational movement, and in automotive suspensions where shear forces act on connecting pins. Understanding single shear is crucial for ensuring joint integrity under operational loads, preventing failure in bridges, cranes, and heavy equipment assemblies.

Failure Modes in Bending vs Single Shear

Failure modes in bending primarily involve tensile failure on the tension side and compressive yielding on the compression side, leading to plastic deformation or fracture. In single shear, failure occurs due to the shearing action along the shear plane, causing the material to fail by shearing across the cross-section. Bending failure often exhibits a combination of tensile cracking and compression buckling, while single shear failure is characterized by a clean shear plane or shear fracture.

Design Considerations for Bending Loads

Design considerations for bending loads emphasize the distribution of tensile and compressive stresses across a beam's cross-section, requiring sufficient moment of inertia and material strength to resist deformation. In bending, the neutral axis location and section modulus are critical parameters for calculating bending stress, ensuring the structure can withstand applied moments without excessive deflection or failure. Unlike single shear, which concentrates forces along a shear plane, bending design prioritizes flexural capacity and structural stability to maintain load-bearing efficiency and serviceability.

Design Considerations for Shear Loads

Design considerations for shear loads require understanding the differences between bending and single shear. Bending stress occurs when a moment induces tension and compression across a cross-section, while single shear involves a force causing one plane of the material to slide relative to another. Ensuring adequate shear strength involves selecting materials with high shear yield strength and designing cross-sections to prevent shear failure or excessive deflection under applied loads.

Material Selection: Bending vs Single Shear

Material selection for bending emphasizes ductility and toughness to withstand deformation without cracking, favoring metals like steel and aluminum alloys. In single shear applications, materials with high shear strength such as hardened steel or titanium are preferred to resist shear forces effectively. Understanding the distinct stress distributions in bending and single shear is critical for optimizing material performance and ensuring structural integrity.

Summary Table: Bending vs Single Shear

The Summary Table: Bending vs Single Shear highlights key differences in stress distribution, failure modes, and load application between the two. Bending involves a combination of tensile and compressive stresses across a beam's cross-section, whereas single shear concentrates stress along a specific shear plane. Understanding these distinctions is crucial for accurate design and material selection in structural engineering applications.

Bending Infographic

libterm.com

libterm.com