A gear train is a series of gears working together to transmit torque and modify rotational speed or direction within machines. Efficient gear train design directly impacts mechanical performance, durability, and power transfer efficiency. Explore the rest of this article to understand how gear trains optimize your mechanical systems.

Table of Comparison

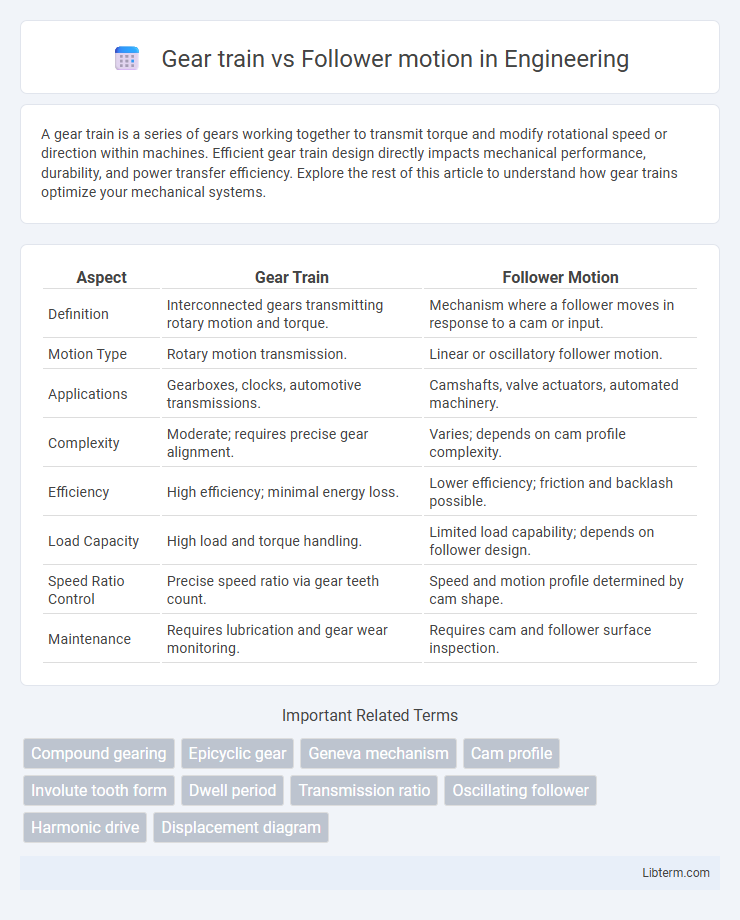

| Aspect | Gear Train | Follower Motion |

|---|---|---|

| Definition | Interconnected gears transmitting rotary motion and torque. | Mechanism where a follower moves in response to a cam or input. |

| Motion Type | Rotary motion transmission. | Linear or oscillatory follower motion. |

| Applications | Gearboxes, clocks, automotive transmissions. | Camshafts, valve actuators, automated machinery. |

| Complexity | Moderate; requires precise gear alignment. | Varies; depends on cam profile complexity. |

| Efficiency | High efficiency; minimal energy loss. | Lower efficiency; friction and backlash possible. |

| Load Capacity | High load and torque handling. | Limited load capability; depends on follower design. |

| Speed Ratio Control | Precise speed ratio via gear teeth count. | Speed and motion profile determined by cam shape. |

| Maintenance | Requires lubrication and gear wear monitoring. | Requires cam and follower surface inspection. |

Introduction to Gear Train and Follower Motion

Gear train consists of multiple gears meshing together to transmit torque and rotational speed within mechanical systems, essential for altering motion and force direction efficiently. Follower motion involves a cam mechanism where the follower traces a specific path governed by the cam profile, converting rotary motion into linear or oscillatory movement. Understanding gear trains improves precision in power transmission, while follower motion is crucial in automation and timing applications.

Fundamental Concepts of Gear Trains

Gear trains consist of multiple gears meshing together to transmit torque and rotational speed from one shaft to another, with the gear ratio determining the mechanical advantage and output speed. The follower motion in gear trains refers to the driven gear's rotational movement as a response to the driver gear's input motion, typically involving changes in angular velocity and torque. Understanding the fundamental concepts of gear trains involves analyzing gear types, pitch circle diameters, velocity ratios, and the transfer of rotational motion through a sequence of interconnected gears.

Principles of Follower Motion

Follower motion principles are based on converting rotary or oscillatory input from a cam or gear into a desired linear or oscillatory output motion. Precise control of displacement, velocity, and acceleration in follower mechanisms is achieved by designing the follower profile to match specific motion laws such as uniform velocity, simple harmonic, or cycloidal motion. Understanding the kinematic constraints and contact forces between the follower and cam surface ensures efficient transmission of motion with minimal wear and optimal dynamic response.

Key Differences Between Gear Trains and Followers

Gear trains consist of multiple gears meshing together to transmit torque and control speed, while followers are components that follow the motion of a cam or gear without directly influencing torque transmission. Gear trains enable precise mechanical advantage and speed variation through their gear ratios, whereas followers primarily convert rotary or oscillatory motion into linear or complex paths. The main difference lies in gear trains actively driving motion and force, whereas followers passively track or replicate motion.

Types of Gear Trains

Gear trains include simple, compound, and planetary configurations, each designed to transmit motion and torque effectively. Simple gear trains consist of two or more gears on separate shafts, enabling straightforward speed and torque conversion. Compound gear trains feature multiple gears on the same shaft for higher gear ratios, while planetary gear trains involve a central sun gear, planet gears, and a ring gear to provide compact, high-torque output with variable speed ratios.

Categories of Follower Mechanisms

Follower mechanisms in mechanical systems are categorized based on their motion types, including oscillating, reciprocating, and sliding followers. Gear trains primarily involve rotating motion where gears transmit power through interlocking teeth. In contrast, follower mechanisms convert rotary motion into linear or oscillatory motion, classified by the follower's path relative to the cam profile, significantly impacting mechanical efficiency and motion control.

Applications of Gear Trains in Industry

Gear trains are extensively used in industrial applications such as conveyors, machine tools, and automotive transmissions to achieve precise speed and torque control. They enable efficient power transmission and motion conversion between rotating shafts, ensuring reliable operation in manufacturing processes and heavy machinery. The ability to customize gear ratios allows gear trains to optimize performance in industries ranging from robotics to aerospace.

Industrial Uses of Follower Motion

Follower motion, commonly utilized in cam mechanisms and Geneva drives, plays a vital role in precise industrial automation and packaging machinery where controlled intermittent motion is essential. Unlike gear trains, which provide continuous rotational power transmission in conveyor systems and heavy machinery, follower motion is effective for indexing, cyclic operations, and timing devices in assembly lines and printing presses. Industries benefit from follower mechanisms for their ability to convert rotary motion into tailored linear or oscillatory movements, optimizing efficiency in specialized manufacturing processes.

Advantages and Limitations: Gear Train vs Follower

Gear trains offer precise and consistent motion transmission with high efficiency and the ability to achieve various speed ratios, making them ideal for mechanical systems requiring accurate torque and speed control. Follower motion mechanisms excel in converting rotary input to complex, customized output motions, beneficial for applications demanding intricate movement patterns, but they may suffer from higher wear and less efficiency compared to gear trains. Limitations of gear trains include noise generation and complex assembly requirements, while followers often face restricted motion range and increased maintenance due to contact stresses.

Choosing the Right Mechanism: Gear Train or Follower Motion

Gear trains offer precise and continuous rotational motion ideal for applications requiring consistent speed ratios and torque transmission. Follower motion mechanisms excel in converting rotary motion to complex, non-uniform output paths, suitable for automated machinery and cams. Choosing between gear train and follower motion depends on the need for rotational accuracy versus customized motion profiles in mechanical system design.

Gear train Infographic

libterm.com

libterm.com