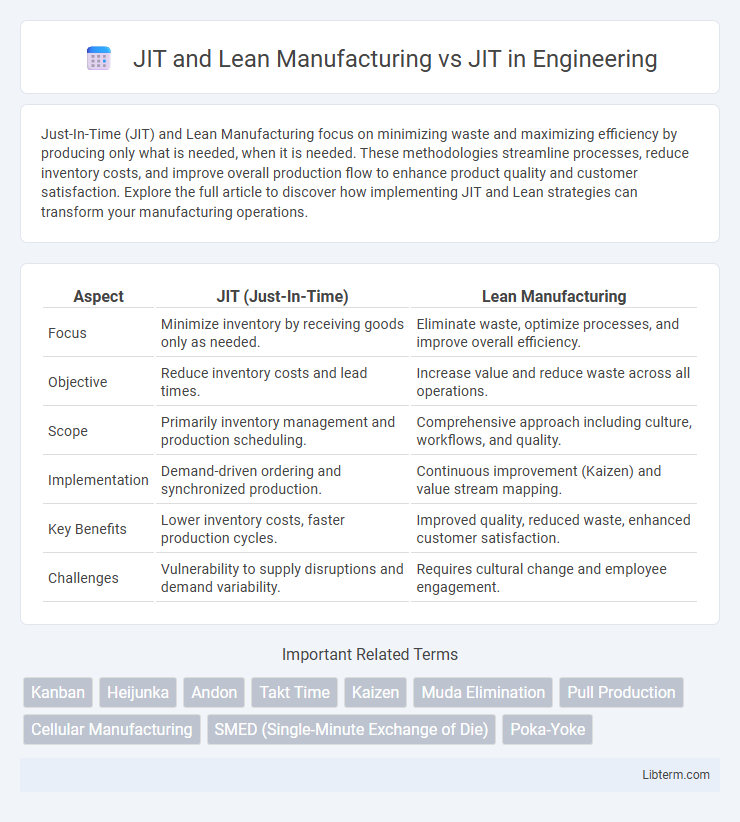

Just-In-Time (JIT) and Lean Manufacturing focus on minimizing waste and maximizing efficiency by producing only what is needed, when it is needed. These methodologies streamline processes, reduce inventory costs, and improve overall production flow to enhance product quality and customer satisfaction. Explore the full article to discover how implementing JIT and Lean strategies can transform your manufacturing operations.

Table of Comparison

| Aspect | JIT (Just-In-Time) | Lean Manufacturing |

|---|---|---|

| Focus | Minimize inventory by receiving goods only as needed. | Eliminate waste, optimize processes, and improve overall efficiency. |

| Objective | Reduce inventory costs and lead times. | Increase value and reduce waste across all operations. |

| Scope | Primarily inventory management and production scheduling. | Comprehensive approach including culture, workflows, and quality. |

| Implementation | Demand-driven ordering and synchronized production. | Continuous improvement (Kaizen) and value stream mapping. |

| Key Benefits | Lower inventory costs, faster production cycles. | Improved quality, reduced waste, enhanced customer satisfaction. |

| Challenges | Vulnerability to supply disruptions and demand variability. | Requires cultural change and employee engagement. |

Understanding JIT: Principles and Benefits

Just-In-Time (JIT) manufacturing focuses on minimizing inventory and reducing waste by producing only what is needed, when it is needed, enhancing operational efficiency and lowering costs. Lean Manufacturing incorporates JIT principles but also emphasizes continuous improvement, value stream mapping, and eliminating all forms of waste beyond inventory, aiming for a holistic optimization of processes. Understanding JIT involves recognizing its role in streamlining production flow, improving quality, and fostering strong supplier relationships to ensure timely delivery and responsiveness.

What is Lean Manufacturing? Core Concepts

Lean manufacturing is a systematic approach to minimizing waste without sacrificing productivity by optimizing processes and improving efficiency. Core concepts include value stream mapping, continuous improvement (Kaizen), just-in-time (JIT) production, and respect for people, all of which aim to enhance flow and reduce excess inventory. Unlike JIT, Lean manufacturing encompasses a broader philosophy that integrates waste reduction across all areas of production while fostering a culture of ongoing improvement.

JIT and Lean: Historical Development

Just-In-Time (JIT) manufacturing emerged in the 1950s within the Toyota Production System, focusing on reducing waste by producing only what is needed, when it is needed. Lean manufacturing evolved from JIT principles, expanding the concept to encompass a broader set of waste-reduction techniques and continuous improvement practices across all organizational processes. The historical development of Lean integrates JIT's inventory and flow efficiencies with systemic improvements in quality, delivery, and employee involvement.

JIT vs Lean: Main Differences

JIT (Just-In-Time) focuses primarily on inventory reduction and delivering materials exactly when needed to minimize waste and holding costs. Lean Manufacturing, however, encompasses a broader approach aimed at optimizing the entire production process by eliminating all forms of waste, improving flow, and enhancing overall value to the customer. While JIT is a component of Lean, Lean Manufacturing integrates tools like Kaizen, 5S, and value stream mapping to drive continuous improvement beyond just inventory management.

Similarities Between JIT and Lean Approaches

Both JIT (Just-in-Time) and Lean Manufacturing emphasize waste reduction by streamlining production processes and enhancing efficiency through continuous improvement. Each approach prioritizes inventory minimization, promoting a pull-based system where materials and products flow only when needed, thereby reducing excess inventory and associated costs. Employee involvement and quality management are central to both methodologies, fostering a culture of problem-solving and maximizing value creation for customers.

Integrating JIT within Lean Manufacturing Systems

Integrating Just-In-Time (JIT) within Lean Manufacturing systems enhances operational efficiency by synchronizing production processes to minimize waste and inventory costs. Lean Manufacturing provides a broader framework emphasizing continuous improvement, value stream mapping, and waste elimination, with JIT serving as a critical component for just-in-time production and inventory control. This integration ensures streamlined workflows, reduced lead times, and improved product quality by aligning JIT's pull-based scheduling with Lean's holistic approach to process optimization.

Key Advantages of JIT and Lean Manufacturing

JIT and Lean Manufacturing minimize inventory costs by synchronizing production closely with demand, reducing waste and enhancing efficiency. Lean emphasizes continuous improvement and eliminates non-value-added activities, while JIT focuses on precise timing to avoid overproduction and excess inventory. Both methodologies improve product quality and increase responsiveness to market changes, driving overall operational excellence.

Challenges in Implementing JIT vs Lean

Implementing Just-In-Time (JIT) poses challenges such as the requirement for highly reliable suppliers and tight inventory control to avoid production delays. Lean Manufacturing, while incorporating JIT principles, faces broader obstacles including cultural resistance, complexity in process re-engineering, and the need for continuous employee involvement to sustain improvements. Both methodologies demand significant organizational commitment, but Lean's holistic approach often complicates implementation due to its integration of waste reduction and value stream mapping beyond inventory management.

Case Studies: Successful JIT and Lean Applications

Case studies demonstrate that companies like Toyota and Dell have successfully implemented JIT combined with Lean Manufacturing, achieving significant reductions in inventory costs and lead times. Lean principles enhance JIT by emphasizing waste elimination, continuous improvement, and value stream mapping, leading to improved operational efficiency and customer satisfaction. Real-world examples highlight measurable gains such as a 30% increase in production efficiency and a 25% reduction in material waste through integrated JIT and Lean strategies.

Choosing the Right Approach: JIT, Lean, or Hybrid Solutions

Choosing the right production strategy involves evaluating Just-In-Time (JIT), Lean Manufacturing, or a hybrid approach based on operational goals and resource availability. JIT focuses on reducing inventory and minimizing waste by producing only what is needed when it is needed, optimizing cash flow and responsiveness. Lean Manufacturing encompasses a broader range of waste reduction techniques and continuous improvement philosophies, making hybrid solutions ideal for companies seeking both inventory efficiency and overall process excellence.

JIT and Lean Manufacturing Infographic

libterm.com

libterm.com