Bridge cranes enable efficient overhead material handling in warehouses and manufacturing facilities, improving workflow and safety. These cranes consist of a girder that runs along tracks fixed to the building structure, allowing precise movement of heavy loads across large spans. Explore the rest of this article to discover how a bridge crane can enhance your operational productivity and safety.

Table of Comparison

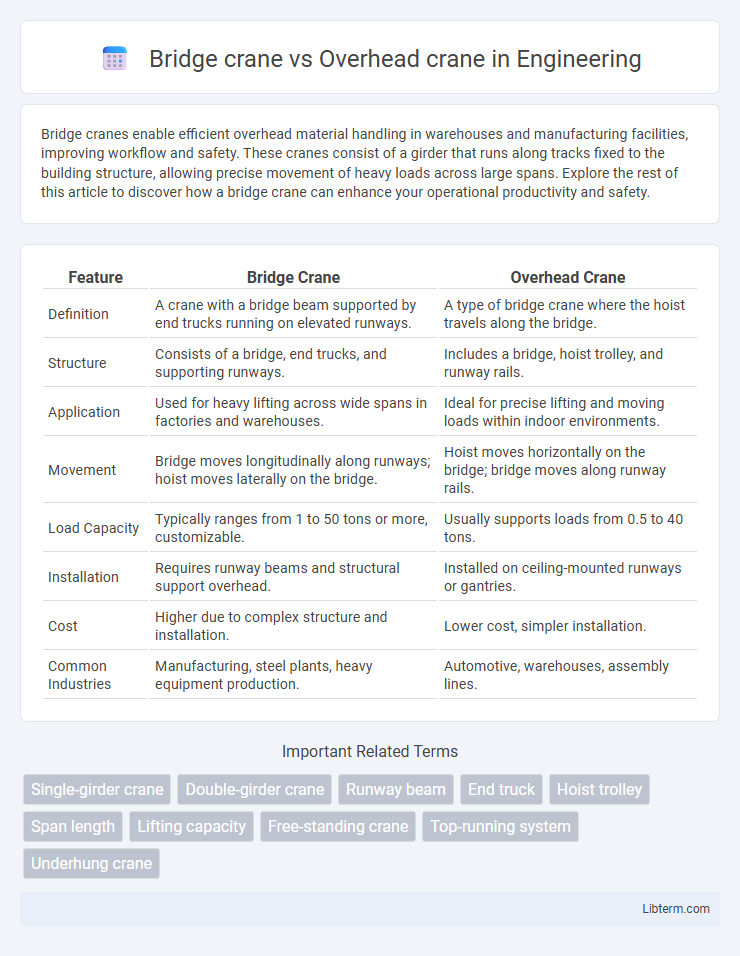

| Feature | Bridge Crane | Overhead Crane |

|---|---|---|

| Definition | A crane with a bridge beam supported by end trucks running on elevated runways. | A type of bridge crane where the hoist travels along the bridge. |

| Structure | Consists of a bridge, end trucks, and supporting runways. | Includes a bridge, hoist trolley, and runway rails. |

| Application | Used for heavy lifting across wide spans in factories and warehouses. | Ideal for precise lifting and moving loads within indoor environments. |

| Movement | Bridge moves longitudinally along runways; hoist moves laterally on the bridge. | Hoist moves horizontally on the bridge; bridge moves along runway rails. |

| Load Capacity | Typically ranges from 1 to 50 tons or more, customizable. | Usually supports loads from 0.5 to 40 tons. |

| Installation | Requires runway beams and structural support overhead. | Installed on ceiling-mounted runways or gantries. |

| Cost | Higher due to complex structure and installation. | Lower cost, simpler installation. |

| Common Industries | Manufacturing, steel plants, heavy equipment production. | Automotive, warehouses, assembly lines. |

Introduction to Bridge Cranes and Overhead Cranes

Bridge cranes and overhead cranes are essential lifting devices used in industrial environments to move heavy loads efficiently. Bridge cranes consist of parallel runways with a traveling bridge spanning the gap, while overhead cranes operate on a fixed runway typically mounted on the building structure. Both cranes improve workflow by enabling precise load handling across large workspaces, but bridge cranes offer more flexibility with their movable bridge system.

Key Differences Between Bridge Cranes and Overhead Cranes

Bridge cranes and overhead cranes are often used interchangeably, but the key difference lies in their structure and operation. Bridge cranes consist of a horizontal beam supported by end trucks that move along runways, allowing the hoist to travel across the bridge, while overhead cranes refer broadly to cranes that operate above the workspace, including bridge cranes and gantry cranes. Bridge cranes are typically fixed to an elevated runway system within a building, providing efficient material handling in manufacturing and warehousing environments.

Structural Design Comparison

Bridge cranes feature a fixed horizontal beam supported by end trucks running on elevated rails, offering robust stability and heavy load capacity ideal for large industrial settings. Overhead cranes, often encompassing bridge cranes, emphasize modular construction with versatile girder designs allowing customization for specific span lengths and load requirements. Structural design differences primarily involve the bridge crane's rigid beam configuration versus the overhead crane's adaptability through various girder types, directly impacting load distribution and operational efficiency.

Load Capacity and Application Areas

Bridge cranes typically offer higher load capacities ranging from a few tons up to 100 tons or more, making them ideal for heavy industrial applications such as steel mills and shipyards. Overhead cranes, while similar in design, often feature lower load capacities generally up to 20 tons and are commonly used in manufacturing plants, warehouses, and assembly lines for lighter material handling. The choice between bridge crane and overhead crane depends heavily on the specific load capacity requirements and the nature of the application area.

Installation and Maintenance Requirements

Bridge cranes typically involve more complex installation due to the need for precise alignment of the bridge runway beams and the integration of the hoist system, requiring professional expertise and careful structural assessment. Overhead cranes, often customized to specific facility dimensions, may demand extensive electrical and mechanical setup, including the installation of control systems and safety mechanisms. Maintenance for both cranes necessitates regular inspection of the hoist, trolley, bridge components, and runway beams, with bridge cranes generally requiring more frequent structural checks due to their span and load distribution.

Cost Analysis: Bridge Crane vs Overhead Crane

Bridge cranes and overhead cranes share similar components but differ in cost structures primarily due to their installation and operational flexibility. Bridge cranes often involve higher upfront costs because of their robust design and installation requirements, whereas overhead cranes typically offer cost savings through easier integration into existing building frameworks. Maintenance expenses tend to be comparable, but bridge cranes may incur additional costs related to frequent customization and heavier load capacities.

Safety Features and Considerations

Bridge cranes and overhead cranes both incorporate advanced safety features such as overload protection, emergency stop functions, and anti-collision systems to prevent accidents during operation. Bridge cranes often include additional safeguards like dual trolley systems and reinforced structural components to enhance stability and minimize risks in heavy-duty industrial environments. Ensuring operator training and regular maintenance is critical for both crane types to maintain optimal safety and compliance with industry standards.

Pros and Cons of Bridge Cranes

Bridge cranes offer high lifting capacity and efficient material handling in large industrial environments, making them ideal for heavy-duty operations. Their versatility allows easy customization for various spans and heights, while the enclosed runway rails reduce maintenance needs and increase safety. However, bridge cranes require significant upfront investment and structural support, which can limit installation flexibility and increase overall project costs.

Pros and Cons of Overhead Cranes

Overhead cranes provide efficient material handling with high load capacity and precise control, making them ideal for heavy-duty industrial environments. Their fixed installation offers stability and safety but limits flexibility in workspace configuration and requires significant upfront investment. Maintenance can be complex and costly, necessitating skilled technicians to ensure operational reliability and minimize downtime.

How to Choose the Right Crane for Your Facility

Choosing the right crane for your facility depends on specific operational needs such as load capacity, workspace layout, and lifting height. Bridge cranes, with their fixed runway system and ability to span large areas, are ideal for heavy-duty lifting in warehouses and manufacturing plants, while overhead cranes offer greater versatility in smaller spaces and dynamic environments. Evaluating factors like load weight, frequency of use, and installation feasibility ensures optimal crane selection for safety and efficiency.

Bridge crane Infographic

libterm.com

libterm.com