Fused deposition modeling (FDM) is an additive manufacturing process that builds objects layer by layer by extruding thermoplastic filament through a heated nozzle. This technique offers precise control over material deposition, making it ideal for rapid prototyping and custom manufacturing. Explore the article to discover how FDM can transform your production workflow and enhance design flexibility.

Table of Comparison

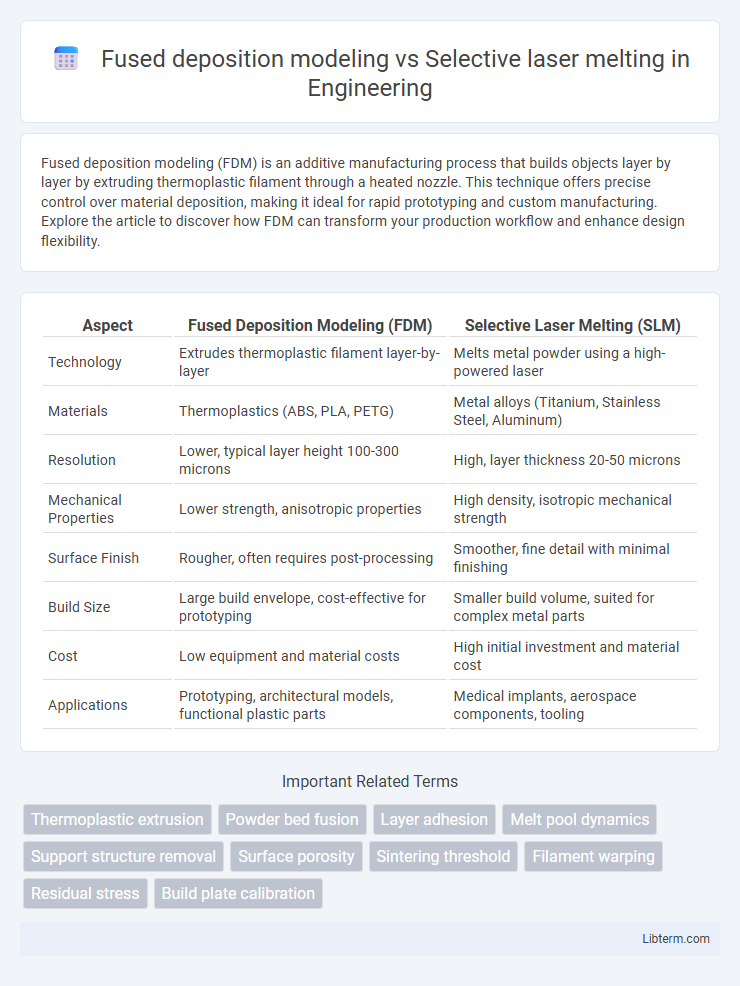

| Aspect | Fused Deposition Modeling (FDM) | Selective Laser Melting (SLM) |

|---|---|---|

| Technology | Extrudes thermoplastic filament layer-by-layer | Melts metal powder using a high-powered laser |

| Materials | Thermoplastics (ABS, PLA, PETG) | Metal alloys (Titanium, Stainless Steel, Aluminum) |

| Resolution | Lower, typical layer height 100-300 microns | High, layer thickness 20-50 microns |

| Mechanical Properties | Lower strength, anisotropic properties | High density, isotropic mechanical strength |

| Surface Finish | Rougher, often requires post-processing | Smoother, fine detail with minimal finishing |

| Build Size | Large build envelope, cost-effective for prototyping | Smaller build volume, suited for complex metal parts |

| Cost | Low equipment and material costs | High initial investment and material cost |

| Applications | Prototyping, architectural models, functional plastic parts | Medical implants, aerospace components, tooling |

Introduction to Fused Deposition Modeling (FDM) and Selective Laser Melting (SLM)

Fused Deposition Modeling (FDM) utilizes thermoplastic filaments heated and extruded layer-by-layer to build parts with precise geometric details, commonly applied in prototyping and functional models. Selective Laser Melting (SLM) employs a high-powered laser to selectively fuse metal powder particles, enabling the production of fully dense, complex metal components with superior mechanical properties. FDM is favored for cost-effective polymer part fabrication, while SLM excels in creating intricate metal parts for aerospace, automotive, and medical industries.

Core Principles: How FDM and SLM Work

Fused Deposition Modeling (FDM) operates by extruding thermoplastic filament through a heated nozzle layer by layer to build a part from the bottom up, relying on controlled deposition and cooling to form precise geometries. Selective Laser Melting (SLM) uses a high-powered laser to selectively melt and fuse fine metal powder particles in a powder bed, creating fully dense metal parts with complex geometries and excellent mechanical properties. FDM is widely favored for prototyping and thermoplastic parts due to its material versatility and cost-effectiveness, whereas SLM excels in producing intricate, high-strength metal components used in aerospace and medical applications.

Materials Used in FDM vs SLM

Fused Deposition Modeling (FDM) primarily uses thermoplastic polymers such as ABS, PLA, and PETG, which are heated and extruded layer-by-layer to build parts. Selective Laser Melting (SLM) processes metal powders including stainless steel, titanium, aluminum, and cobalt-chrome alloys, using a high-powered laser to fuse particles into dense, fully solid components. The distinct materials in FDM and SLM result in different mechanical properties, surface finishes, and application areas, with FDM suited for prototyping and SLM ideal for functional metal parts.

Print Quality and Surface Finish Comparison

Fused Deposition Modeling (FDM) typically produces parts with visible layer lines and a rougher surface finish due to the extrusion of thermoplastic filaments, resulting in lower print quality compared to Selective Laser Melting (SLM). SLM uses a laser to sinter metal powder layer by layer, achieving high-resolution details, superior dimensional accuracy, and a smoother surface finish ideal for functional metal prototypes and end-use components. Post-processing techniques like sanding and coating are often required to improve FDM surface quality, whereas SLM parts generally require less intensive finishing due to their inherent precision and fine microstructure.

Mechanical Properties of FDM and SLM Parts

Fused Deposition Modeling (FDM) parts generally exhibit lower tensile strength and surface finish quality compared to Selective Laser Melting (SLM) components due to the layer-by-layer deposition of thermoplastic materials, resulting in anisotropic mechanical properties and possible voids. In contrast, SLM parts, fabricated by melting metal powders with a laser, achieve superior density, strength, and hardness, demonstrating near-wrought metal mechanical performance with enhanced fatigue resistance and isotropic behavior. The higher resolution and metallurgical bonding in SLM parts make them suitable for critical load-bearing applications, while FDM remains favored for rapid prototyping with moderate mechanical requirements.

Cost Analysis: FDM vs SLM

Fused Deposition Modeling (FDM) generally offers significantly lower production costs compared to Selective Laser Melting (SLM) due to cheaper raw materials like thermoplastic filaments and reduced equipment expenses. SLM involves high energy consumption, expensive metal powders, and intricate post-processing, which contribute to elevated operational costs. While FDM suits low-budget prototyping and functional parts, SLM is preferred for complex, high-strength metal components despite its higher investment.

Build Speed and Production Scalability

Fused deposition modeling (FDM) offers faster build speeds due to its layer-by-layer extrusion process, making it suitable for rapid prototyping and low-volume production runs. Selective laser melting (SLM) provides higher precision and material density, but its slower scanning and melting rates limit build speed, impacting large-scale production scalability. While FDM excels in cost-effective, scalable manufacturing of polymer parts, SLM is preferred for complex, high-strength metal components despite longer build times.

Design Flexibility and Geometric Capabilities

Fused Deposition Modeling (FDM) offers moderate design flexibility with the ability to create complex geometries using thermoplastic materials, but it is limited by layer resolution and support structure requirements. Selective Laser Melting (SLM) excels in geometric capabilities, enabling intricate and highly detailed metal parts with fine features and internal channels due to its precise laser fusion process. SLM supports complex designs unattainable by FDM, especially in applications requiring high strength and metal material properties.

Typical Applications for FDM and SLM

Fused Deposition Modeling (FDM) is predominantly used for prototyping, tooling, and low-cost production parts in automotive, aerospace, and consumer goods industries due to its ability to print thermoplastic materials with ease. Selective Laser Melting (SLM) is favored for producing complex metal parts with high mechanical properties in aerospace, medical implants, and high-performance engineering applications where precision and material strength are critical. FDM excels in rapid iteration and functional prototypes, while SLM is ideal for fully dense, intricate metal components requiring superior structural integrity.

Choosing Between FDM and SLM: Key Considerations

Choosing between Fused Deposition Modeling (FDM) and Selective Laser Melting (SLM) depends primarily on material requirements, precision, and application complexity; FDM excels in producing cost-effective thermoplastic prototypes with moderate accuracy, while SLM enables high-strength, intricate metal parts with superior mechanical properties. Surface finish and post-processing time differ significantly, with SLM generally requiring more extensive finishing but yielding denser, more durable components suitable for aerospace or medical implants. Consider production volume and budget constraints as FDM offers quicker turnaround for low-volume runs and prototyping, whereas SLM suits high-performance, critical applications despite higher equipment and operational costs.

Fused deposition modeling Infographic

libterm.com

libterm.com