Mohs hardness is a scale used to measure the scratch resistance of various minerals, ranging from talc at 1 to diamond at 10. Understanding this scale helps you identify and compare the durability of materials in applications like jewelry, construction, and manufacturing. Discover how Mohs hardness impacts your choice of materials by reading the rest of the article.

Table of Comparison

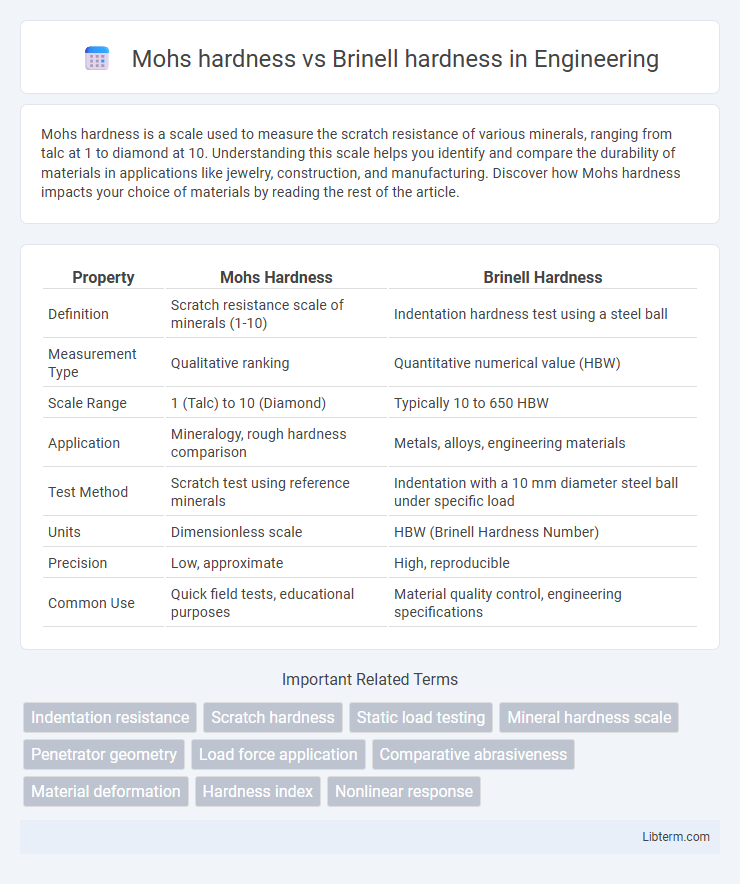

| Property | Mohs Hardness | Brinell Hardness |

|---|---|---|

| Definition | Scratch resistance scale of minerals (1-10) | Indentation hardness test using a steel ball |

| Measurement Type | Qualitative ranking | Quantitative numerical value (HBW) |

| Scale Range | 1 (Talc) to 10 (Diamond) | Typically 10 to 650 HBW |

| Application | Mineralogy, rough hardness comparison | Metals, alloys, engineering materials |

| Test Method | Scratch test using reference minerals | Indentation with a 10 mm diameter steel ball under specific load |

| Units | Dimensionless scale | HBW (Brinell Hardness Number) |

| Precision | Low, approximate | High, reproducible |

| Common Use | Quick field tests, educational purposes | Material quality control, engineering specifications |

Introduction to Hardness Testing

Mohs hardness and Brinell hardness are fundamental scales used in material science to evaluate the resistance of materials to deformation and scratching. Mohs hardness measures scratch resistance on a scale from 1 (talc) to 10 (diamond), making it ideal for quick, qualitative assessments of minerals. Brinell hardness quantifies the indentation resistance by measuring the diameter of an impression made by a hardened steel or carbide ball under a specific load, providing a precise, quantitative value used extensively in engineering and metallurgical applications.

Understanding Mohs Hardness Scale

The Mohs hardness scale measures a material's resistance to scratching by ranking minerals from 1 (talc) to 10 (diamond), providing a qualitative assessment of surface hardness. Unlike the Brinell hardness test, which quantifies hardness by indenting the material with a steel or carbide ball and calculating the resistance to deformation, the Mohs scale emphasizes comparative scratch resistance. Understanding the Mohs scale is crucial for identifying minerals and assessing durability in applications where surface wear is a primary concern.

Overview of Brinell Hardness Test

The Brinell Hardness Test measures material hardness by pressing a hardened steel or tungsten carbide ball into the specimen under a specified load, producing an indentation whose diameter is measured to calculate the Brinell Hardness Number (BHN). Unlike the Mohs scale, which ranks scratch resistance on a qualitative scale from 1 to 10, the Brinell test provides a quantitative value that reflects the material's ability to withstand indentation and deformation. This method is widely used for metals and alloys, offering reliable hardness data for engineering applications where surface resistance is critical.

Measurement Methods: Mohs vs Brinell

Mohs hardness measures a material's scratch resistance by comparing it to ten reference minerals ranked from talc (1) to diamond (10), relying on qualitative scratching tests. Brinell hardness quantifies material resistance to indentation using a standardized steel or carbide ball pressed under a specified load, with the indentation diameter measured to calculate a numerical hardness value. While Mohs provides a relative scale for minerals and simple identification, Brinell offers precise, reproducible data essential for engineering and metallurgical applications.

Materials Tested with Mohs and Brinell

Mohs hardness primarily tests the scratch resistance of minerals and ceramics by ranking materials on a scale from talc (1) to diamond (10), making it ideal for geological samples and gemstones. Brinell hardness evaluates the indentation resistance of metals and alloys through a steel or carbide ball pressed into the surface, providing precise measurements for steel, cast iron, and aluminum components. While Mohs is qualitative and simple, Brinell offers quantitative data essential for engineering materials subjected to mechanical stress.

Accuracy and Precision: Comparing Results

Mohs hardness measures scratch resistance on a scale from 1 to 10, offering qualitative results that vary with surface conditions and operator technique, leading to lower precision. Brinell hardness uses a standardized indentation test with a steel or carbide ball and a specified load, producing quantitative and reproducible values that enhance accuracy and precision in material hardness evaluation. Consequently, Brinell hardness is preferred for detailed hardness analysis where exact measurement consistency is critical.

Application Areas for Each Hardness Scale

Mohs hardness is primarily used in geology and mineralogy to identify and classify minerals based on scratch resistance, making it ideal for field identification and educational purposes. Brinell hardness is widely applied in engineering and metallurgy to measure the resistance of metals and alloys to indentation, crucial for assessing material properties in manufacturing, quality control, and mechanical design. Each scale serves distinct industries: Mohs for natural mineral assessment and Brinell for evaluating industrial metal components.

Advantages and Limitations: Mohs vs Brinell

Mohs hardness offers a quick and simple method for estimating mineral scratch resistance, making it ideal for field identification but lacks precision and quantitative data. Brinell hardness provides accurate, quantitative measurements of materials' resistance to indentation, essential for engineering applications, yet requires specialized equipment and can be unsuitable for very small or thin samples. Mohs is advantageous for its ease and speed, while Brinell excels in detailed materials testing, highlighting the trade-off between simplicity and accuracy.

Interpreting Hardness Values across Different Scales

Mohs hardness measures scratch resistance on a scale from 1 to 10, while Brinell hardness quantifies resistance to indentation using a specific load and ball size, producing numerical values typically ranging from 100 to 600 HB. Interpreting hardness values across these scales requires understanding that Mohs is qualitative and ordinal, reflecting relative scratch resistance, whereas Brinell provides quantitative, continuous data related to material strength and wear resistance. Direct conversions are approximate, but materials with a Mohs hardness of 7 (like quartz) correspond to Brinell hardness values near 750 MPa, enabling engineers to compare durability and suitability for applications.

Choosing the Right Hardness Test for Your Material

Selecting the appropriate hardness test depends on material properties and application requirements. The Mohs hardness test, ranging from 1 to 10, is ideal for quickly assessing surface scratch resistance of minerals and softer materials. The Brinell hardness test uses a steel or carbide ball under load to measure indentation size, offering precise results for metals and alloys with coarse structures.

Mohs hardness Infographic

libterm.com

libterm.com