Adhesive joints provide strong, durable bonds by distributing stress evenly across bonded surfaces, reducing the risk of material failure. Understanding the properties of adhesives and surface preparation techniques is essential for optimizing joint performance in various applications. Explore the rest of this article to learn how to maximize the strength and reliability of your adhesive joints.

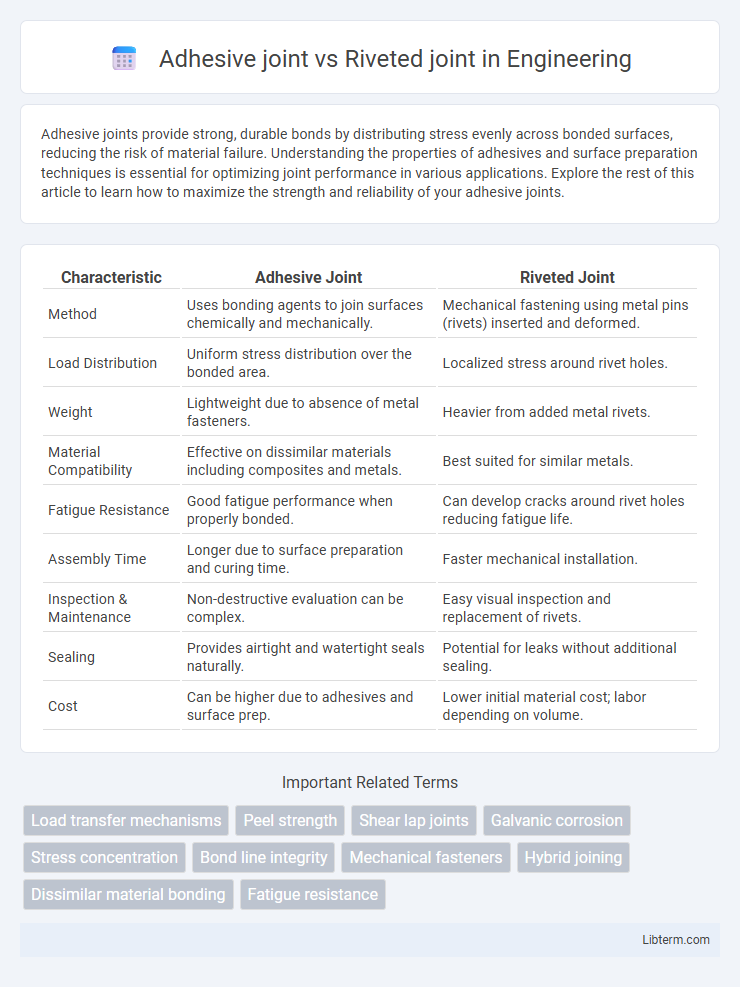

Table of Comparison

| Characteristic | Adhesive Joint | Riveted Joint |

|---|---|---|

| Method | Uses bonding agents to join surfaces chemically and mechanically. | Mechanical fastening using metal pins (rivets) inserted and deformed. |

| Load Distribution | Uniform stress distribution over the bonded area. | Localized stress around rivet holes. |

| Weight | Lightweight due to absence of metal fasteners. | Heavier from added metal rivets. |

| Material Compatibility | Effective on dissimilar materials including composites and metals. | Best suited for similar metals. |

| Fatigue Resistance | Good fatigue performance when properly bonded. | Can develop cracks around rivet holes reducing fatigue life. |

| Assembly Time | Longer due to surface preparation and curing time. | Faster mechanical installation. |

| Inspection & Maintenance | Non-destructive evaluation can be complex. | Easy visual inspection and replacement of rivets. |

| Sealing | Provides airtight and watertight seals naturally. | Potential for leaks without additional sealing. |

| Cost | Can be higher due to adhesives and surface prep. | Lower initial material cost; labor depending on volume. |

Introduction to Adhesive and Riveted Joints

Adhesive joints utilize specialized bonding agents to create a continuous interface between materials, offering uniform stress distribution and improved fatigue resistance in composite and metal assemblies. Riveted joints, composed of mechanical fasteners such as metal pins or bolts, provide a high-strength, reliable connection widely used in aerospace and structural applications for metal-to-metal joining. Both methods are selected based on factors like load type, environmental exposure, weight constraints, and material compatibility.

Basic Principles of Adhesive Joints

Adhesive joints bond materials by chemically or physically adhering surfaces using polymers that cure to form a continuous, stress-distributing bondline. They rely on surface preparation, adhesive selection, and curing conditions to achieve optimal strength and durability, creating joints resistant to fatigue, vibration, and corrosion. Unlike riveted joints, adhesive bonding avoids stress concentration points, providing a smooth, lightweight connection ideal for composite and dissimilar materials.

Fundamentals of Riveted Joints

Riveted joints rely on mechanical fastening using metal pins called rivets, which generate clamping force through deformation when hammered or pressed. The strength of a riveted joint depends on rivet material, size, pitch, and the type of load applied, typically shear or tensile forces. Riveted joints offer high durability and resistance to fatigue, making them ideal for structural applications in aircraft, bridges, and shipbuilding.

Comparative Strength and Load Distribution

Adhesive joints provide uniform load distribution by bonding surfaces at a molecular level, reducing stress concentrations and enhancing fatigue resistance compared to riveted joints. Riveted joints rely on mechanical fasteners that create localized stress points around each rivet, which can lead to stress risers and potential failure under dynamic loads. While riveted joints often offer higher immediate shear strength, adhesive joints excel in distributing loads evenly across the bonded interface, improving joint durability under cyclic and impact loading conditions.

Material Compatibility and Application Scope

Adhesive joints excel in bonding dissimilar materials, such as metals, composites, and plastics, providing uniform stress distribution and reducing the risk of galvanic corrosion. Riveted joints are primarily suited for similar or compatible metals, offering mechanical fastening ideal for high-load and dynamic applications where peel and shear forces are significant. The application scope of adhesive joints includes aerospace, automotive, and electronics industries emphasizing lightweight and aerodynamic designs, while riveted joints remain prevalent in traditional structural assemblies like aircraft fuselage and bridges requiring robust mechanical integrity.

Durability and Environmental Resistance

Adhesive joints offer superior durability by distributing stress evenly across bonded surfaces, reducing the risk of localized failures common in riveted joints. These joints provide enhanced resistance to environmental factors such as moisture, corrosion, and temperature fluctuations, which often degrade rivet materials and compromise structural integrity. In contrast, riveted joints can suffer from galvanic corrosion and loosening over time, diminishing their long-term performance in harsh conditions.

Manufacturing and Assembly Processes

Adhesive joints enable streamlined manufacturing by eliminating the need for drilling holes, reducing material stress and improving weight savings in assembly processes. Riveted joints require precise hole alignment and drilling, increasing production time and potentially weakening structural integrity due to stress concentrations. Automated adhesive dispensing systems enhance assembly efficiency, whereas riveted joints often involve labor-intensive installation with mechanical fastening tools.

Cost-Effectiveness and Economic Considerations

Adhesive joints offer cost-effectiveness by reducing material usage and eliminating the need for secondary machining and fasteners, leading to lower overall production expenses. Riveted joints incur higher labor and maintenance costs due to the complexity of installation and the potential for corrosion at rivet sites. Economic considerations favor adhesive bonding in high-volume manufacturing where weight savings and streamlined assembly translate into significant long-term financial benefits.

Typical Applications in Industry

Adhesive joints are widely used in the automotive and aerospace industries for bonding lightweight composite materials and metals, providing uniform stress distribution and corrosion resistance. Riveted joints find typical applications in aerospace and structural engineering, where high-load bearing connections and mechanical fastening reliability are essential. Industries select adhesive joints for aerodynamic surface assembly, while riveted joints are preferred in aircraft fuselage and bridge construction due to their mechanical strength.

Choosing Between Adhesive and Riveted Joints

Choosing between adhesive and riveted joints depends on load type, material compatibility, and environmental conditions. Adhesive joints excel in distributing stress evenly, offering corrosion resistance and maintaining surface integrity, ideal for composites and lightweight materials. Riveted joints provide superior mechanical strength and reliability in high-vibration or load-bearing applications, commonly used in aerospace and heavy machinery.

Adhesive joint Infographic

libterm.com

libterm.com