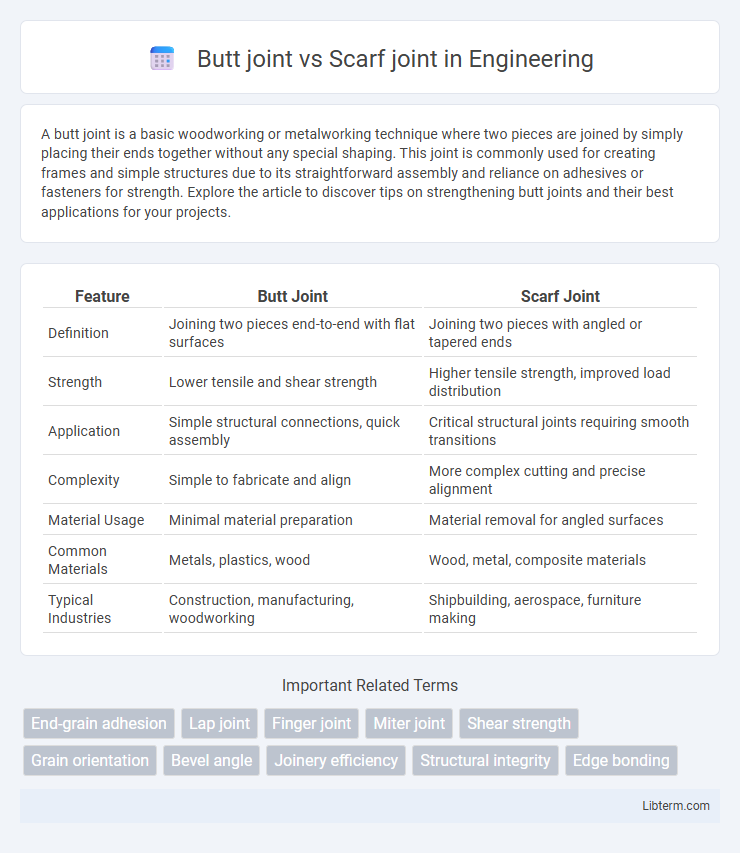

A butt joint is a basic woodworking or metalworking technique where two pieces are joined by simply placing their ends together without any special shaping. This joint is commonly used for creating frames and simple structures due to its straightforward assembly and reliance on adhesives or fasteners for strength. Explore the article to discover tips on strengthening butt joints and their best applications for your projects.

Table of Comparison

| Feature | Butt Joint | Scarf Joint |

|---|---|---|

| Definition | Joining two pieces end-to-end with flat surfaces | Joining two pieces with angled or tapered ends |

| Strength | Lower tensile and shear strength | Higher tensile strength, improved load distribution |

| Application | Simple structural connections, quick assembly | Critical structural joints requiring smooth transitions |

| Complexity | Simple to fabricate and align | More complex cutting and precise alignment |

| Material Usage | Minimal material preparation | Material removal for angled surfaces |

| Common Materials | Metals, plastics, wood | Wood, metal, composite materials |

| Typical Industries | Construction, manufacturing, woodworking | Shipbuilding, aerospace, furniture making |

Introduction to Butt Joints and Scarf Joints

Butt joints are basic woodworking joints where two pieces of wood are joined end to end without any special shaping, relying mainly on glue or fasteners for strength. Scarf joints involve angled cuts on the ends of the wood pieces, creating a larger gluing surface that enhances structural integrity and aesthetic appeal. Both joints are commonly used in carpentry, with scarf joints preferred for longer spans and improved load distribution.

Fundamental Differences Between Butt and Scarf Joints

Butt joints connect two pieces of material end-to-end with a simple square cut, offering ease of construction but limited strength and durability. Scarf joints involve angled or tapered cuts that overlap, increasing the bonding surface area and enhancing structural integrity and resistance to tensile forces. The fundamental difference lies in the joint geometry, where butt joints prioritize simplicity while scarf joints optimize strength and stability in woodworking or metalworking applications.

Structural Strength Comparison

A scarf joint provides greater structural strength than a butt joint due to the increased surface area for adhesive bonding and the overlapping design, which distributes stress more evenly. Butt joints rely on end grain adhesion, which is weaker and more prone to failure under tension or shear forces. In applications requiring enhanced load-bearing capacity and durability, scarf joints outperform butt joints in resisting mechanical stresses.

Ease of Construction and Assembly

Butt joints are easier to construct and assemble, requiring minimal cutting and straightforward alignment, making them ideal for quick projects and simple applications. Scarf joints demand more precision in cutting angled surfaces and fitting them accurately, resulting in increased assembly time and complexity. The ease of construction for butt joints makes them preferable in scenarios prioritizing speed, while scarf joints offer stronger, more seamless connections despite their challenging assembly.

Applications in Woodworking and Carpentry

Butt joints are commonly used in woodworking for simple frame construction, cabinetry, and basic furniture where quick assembly and minimal strength are required. Scarf joints find applications in fine woodworking and structural carpentry, especially for joining longer lengths of timber in beams, molding, and trim, providing enhanced strength and seamless appearance. Woodworkers prefer scarf joints in load-bearing structures for their ability to distribute stress evenly and improve aesthetic continuity.

Visual Appearance and Seam Visibility

Butt joints typically exhibit a more noticeable seam due to the direct end-to-end connection of materials, making the joint line visually prominent. Scarf joints create a longer, angled bonding surface that blends more seamlessly with the surrounding material, reducing seam visibility and enhancing aesthetic appeal. This angled overlap disperses stress better and provides a smoother transition, making scarf joints preferable for applications where visual appearance is critical.

Material Efficiency and Waste Considerations

Butt joints typically result in higher material waste as the ends of components are cut square and joined directly, often requiring more trimming and allowing less overlap for stress distribution. Scarf joints optimize material efficiency by creating angled cuts that increase the bonding surface area, reducing the need for additional fasteners or adhesives and minimizing scrap materials. The increased overlap in scarf joints leads to stronger connections, allowing for thinner or fewer joining materials, which further decreases overall waste.

Cost Implications for Each Joint Type

Butt joints are generally more cost-effective due to their simple design and ease of fabrication, requiring less labor and minimal specialized equipment. Scarf joints, while stronger and more aesthetically pleasing, involve complex cutting and fitting that increase production time and labor costs. The higher precision needed for scarf joints often results in elevated material waste and expenses compared to butt joints.

Longevity and Durability Factors

Butt joints are simpler and easier to create but tend to be weaker and less durable due to limited glue surface area, making them prone to failure under stress or environmental changes. Scarf joints offer increased longevity by providing a larger bonding surface and better load distribution, enhancing strength and resistance to warping or splitting over time. The durability of scarf joints is superior in applications requiring sustained mechanical load and exposure to varying humidity or temperature conditions.

Choosing the Right Joint for Your Project

Selecting the appropriate joint for your project depends on the load requirements and aesthetics; a butt joint offers simplicity and ease of assembly for non-structural applications, while a scarf joint provides superior tensile strength and a smoother profile for joining long pieces of wood. Consider the type of stress the joint will endure--tension, compression, or bending--to determine which joint ensures durability and stability. Material thickness and finish quality also influence the decision, as scarf joints excel in maintaining continuous grain lines, making them ideal for visible woodworking projects.

Butt joint Infographic

libterm.com

libterm.com