Fouling occurs when unwanted materials accumulate on surfaces, impacting equipment efficiency and performance. Common in industries such as water treatment, marine, and manufacturing, it leads to increased energy consumption and maintenance costs. Discover effective strategies to prevent and manage fouling by reading the rest of the article.

Table of Comparison

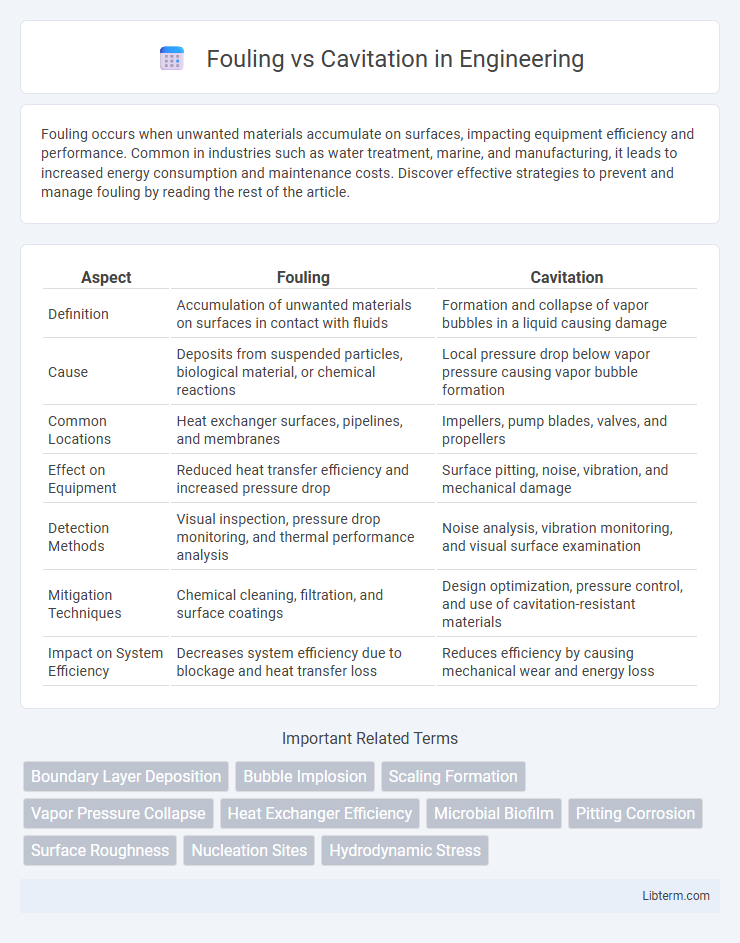

| Aspect | Fouling | Cavitation |

|---|---|---|

| Definition | Accumulation of unwanted materials on surfaces in contact with fluids | Formation and collapse of vapor bubbles in a liquid causing damage |

| Cause | Deposits from suspended particles, biological material, or chemical reactions | Local pressure drop below vapor pressure causing vapor bubble formation |

| Common Locations | Heat exchanger surfaces, pipelines, and membranes | Impellers, pump blades, valves, and propellers |

| Effect on Equipment | Reduced heat transfer efficiency and increased pressure drop | Surface pitting, noise, vibration, and mechanical damage |

| Detection Methods | Visual inspection, pressure drop monitoring, and thermal performance analysis | Noise analysis, vibration monitoring, and visual surface examination |

| Mitigation Techniques | Chemical cleaning, filtration, and surface coatings | Design optimization, pressure control, and use of cavitation-resistant materials |

| Impact on System Efficiency | Decreases system efficiency due to blockage and heat transfer loss | Reduces efficiency by causing mechanical wear and energy loss |

Understanding Fouling: Definition and Causes

Fouling refers to the accumulation of unwanted materials, such as biological organisms, minerals, and debris, on surfaces within fluid systems, leading to reduced efficiency and increased operational costs. Common causes of fouling include particulate deposition, microbial growth, chemical reactions, and scaling caused by mineral precipitation. Identifying specific fouling mechanisms is crucial for effective prevention and maintenance in industrial applications.

Cavitation Explained: Key Concepts and Mechanisms

Cavitation occurs when vapor bubbles form in a liquid due to local pressure drops below the vapor pressure, leading to bubble collapse that generates shock waves, causing surface damage and performance loss in hydraulic systems. This phenomenon primarily results from high-velocity fluid flow or rapid pressure changes in pumps, propellers, and turbines. Understanding cavitation mechanisms is crucial for designing equipment that minimizes erosion, noise, and vibration associated with bubble implosion.

Major Differences Between Fouling and Cavitation

Fouling refers to the accumulation of unwanted materials such as biological organisms, scale, or sediments on surfaces, primarily causing reduced heat transfer efficiency and increased energy consumption in heat exchangers. Cavitation is the formation and violent collapse of vapor bubbles in a liquid near a surface, leading to pitting, erosion, and mechanical damage to pumps or propellers. Major differences include fouling being a surface contamination problem affecting thermal performance, while cavitation is a fluid dynamic phenomenon causing physical damage and noise due to pressure fluctuations.

Types of Fouling in Industrial Systems

Fouling in industrial systems encompasses various types, including particulate, biological, chemical, and corrosion fouling, each affecting heat exchangers, pipelines, and equipment differently. Particulate fouling results from solid deposits, biological fouling involves microbial growth, chemical fouling forms from precipitated compounds, and corrosion fouling occurs due to corrosive interactions damaging surfaces. Understanding these fouling types is crucial for selecting appropriate cleaning methods and preventing efficiency loss in industrial operations.

Common Cavitation Types in Mechanical Applications

Common cavitation types in mechanical applications include volumetric, inertial, and non-inertial cavitation, each affecting system performance differently. Volumetric cavitation arises from vapor bubble formation due to localized pressure drops, common in pumps and propellers, leading to efficiency loss and material erosion. Inertial cavitation involves violent bubble collapse causing shock waves that damage surfaces, while non-inertial cavitation features stable bubbles oscillating without collapse, influencing heat transfer and fluid mixing.

Impact of Fouling on System Performance

Fouling significantly reduces system performance by obstructing fluid flow and diminishing heat transfer efficiency, leading to increased energy consumption and operational costs. The accumulation of deposits on heat exchanger surfaces or pump components causes pressure drops and compromised flow rates, which can accelerate equipment wear and lead to premature failure. Regular maintenance and cleaning protocols are essential to mitigate fouling effects and maintain optimal system reliability and efficiency.

Effects of Cavitation on Equipment Longevity

Cavitation causes significant damage to equipment by creating microjets and shock waves that erode metal surfaces, leading to pitting and surface fatigue. This deterioration accelerates wear and reduces the lifespan of pumps, propellers, and turbines, increasing maintenance costs and operational downtimes. Unlike fouling, which primarily decreases efficiency through surface blockage, cavitation physically compromises the structural integrity of components.

Detection Methods for Fouling and Cavitation

Detection methods for fouling commonly include vibration analysis, thermal imaging, and ultrasonic testing to identify deposit buildup and flow restrictions. Cavitation detection typically relies on acoustic emission sensors, high-frequency vibration monitoring, and pressure fluctuation analysis to detect vapor bubble formation and collapse. Early and accurate detection through these techniques enhances maintenance strategies and prevents equipment damage in pumps, turbines, and heat exchangers.

Prevention and Control Strategies for Both Issues

Fouling prevention relies on regular cleaning, chemical treatments, and selecting anti-fouling coatings to inhibit deposit buildup on surfaces. Cavitation control strategies involve optimizing fluid velocity, reducing pressure drops, and using materials resistant to cavitation erosion to maintain equipment integrity. Implementing monitoring systems and routine inspections enhances early detection and effective management of both fouling and cavitation in industrial processes.

Case Studies: Fouling vs Cavitation in Real-world Scenarios

Case studies reveal that fouling in heat exchangers leads to decreased thermal efficiency and increased energy consumption due to biofilm and mineral deposits, while cavitation in pumps often causes physical damage such as pitting and vibration, reducing equipment lifespan. In industrial water systems, fouling from scale formation triggered a 15% drop in heat transfer efficiency over six months, whereas cavitation caused a 30% increase in maintenance costs due to impeller wear within three months. Addressing these challenges requires targeted cleaning protocols for fouling and operational adjustments like pressure regulation to mitigate cavitation damage.

Fouling Infographic

libterm.com

libterm.com