Flat slabs offer a streamlined construction method by eliminating beams, which reduces floor height and provides greater architectural flexibility. This design enhances load distribution and simplifies formwork, making it ideal for commercial and residential buildings. Discover how flat slabs can improve your project's efficiency and aesthetics by reading the full article.

Table of Comparison

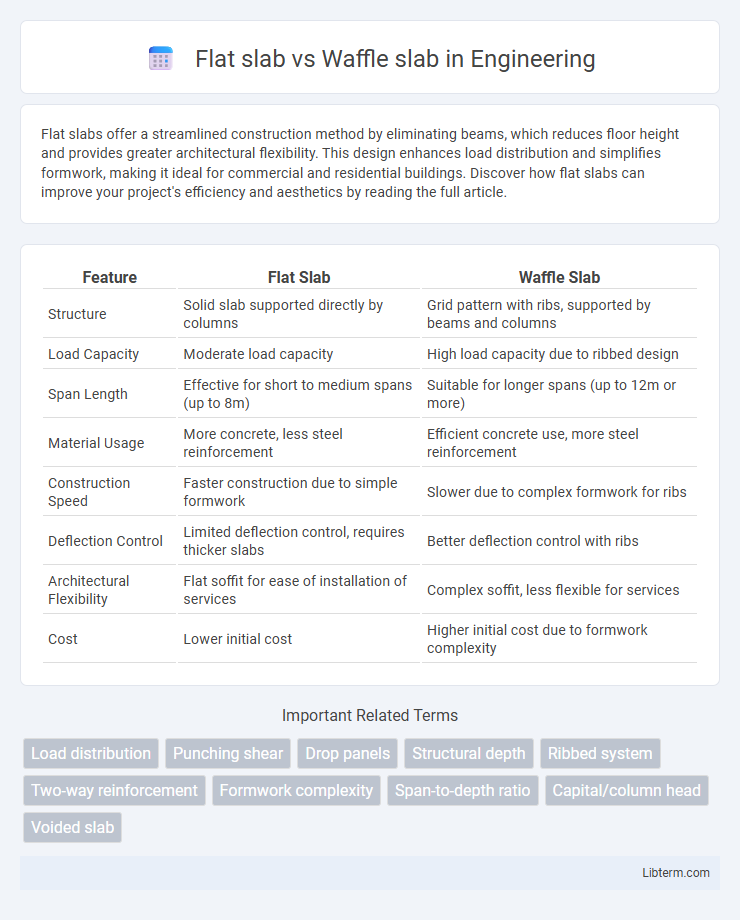

| Feature | Flat Slab | Waffle Slab |

|---|---|---|

| Structure | Solid slab supported directly by columns | Grid pattern with ribs, supported by beams and columns |

| Load Capacity | Moderate load capacity | High load capacity due to ribbed design |

| Span Length | Effective for short to medium spans (up to 8m) | Suitable for longer spans (up to 12m or more) |

| Material Usage | More concrete, less steel reinforcement | Efficient concrete use, more steel reinforcement |

| Construction Speed | Faster construction due to simple formwork | Slower due to complex formwork for ribs |

| Deflection Control | Limited deflection control, requires thicker slabs | Better deflection control with ribs |

| Architectural Flexibility | Flat soffit for ease of installation of services | Complex soffit, less flexible for services |

| Cost | Lower initial cost | Higher initial cost due to formwork complexity |

Introduction to Flat Slab and Waffle Slab Systems

Flat slab systems feature a uniform thickness concrete slab supported directly by columns without beams, providing a smooth ceiling and reducing floor-to-floor height. Waffle slab systems incorporate a grid of ribs on the underside, enhancing structural rigidity and allowing longer spans with reduced material usage. Both systems optimize load distribution but differ in formwork complexity and architectural integration.

Structural Overview: Flat Slab vs Waffle Slab

Flat slabs feature a uniform thickness with direct column support, enabling faster construction and simplified formwork, ideal for buildings with frequent column placements. Waffle slabs consist of a grid of ribs on the underside, providing enhanced load-bearing capacity and reduced slab thickness, optimizing material usage for longer spans and heavier loads. Structural efficiency in waffle slabs comes from the two-way ribbed system, while flat slabs offer better architectural flexibility and ease of integration with mechanical systems.

Key Design Features and Differences

Flat slabs provide a smooth ceiling with no beams, supported directly by columns, ideal for quick construction and flexible layouts. Waffle slabs consist of a grid of ribs on the underside, offering enhanced load-bearing capacity and stiffness, suitable for longer spans and heavy loads. Key differences include flat slabs' reduced formwork complexity and uniform thickness versus waffle slabs' increased depth and material use for superior structural performance.

Load Distribution and Structural Performance

Flat slabs distribute loads directly to columns through a uniform slab thickness, offering efficient load transfer for moderate spans but limited shear resistance. Waffle slabs incorporate ribs in two directions, enhancing load distribution by increasing stiffness and reducing bending moments over larger spans. Structural performance of waffle slabs surpasses flat slabs in handling heavy loads and minimizing deflections due to their reinforced ribbing and optimized material usage.

Material Usage and Construction Techniques

Flat slabs require less formwork and use fewer materials due to their simplified design, making them cost-effective for medium-span structures. Waffle slabs incorporate a grid of ribs beneath the slab, increasing material use but providing superior load-bearing capacity and reduced slab thickness for long spans. Construction of flat slabs involves straightforward casting directly on column supports, while waffle slabs demand intricate formwork and beam molds, extending construction time and labor.

Span Capabilities and Architectural Flexibility

Flat slabs provide moderate span capabilities typically up to 8 meters, allowing for straightforward construction and reduced floor-to-floor height, which benefits low to mid-rise buildings. Waffle slabs offer superior span capabilities often exceeding 10 meters, thanks to their two-way ribbed design that enhances load distribution and structural efficiency. Architectural flexibility is greater with waffle slabs as their distinctive grid pattern enables creative ceiling treatments and integration of mechanical systems, while flat slabs support simpler, more versatile layouts without the need for beams.

Cost Comparison: Flat Slab vs Waffle Slab

Flat slabs typically incur lower initial costs due to simpler formwork and faster construction times, making them budget-friendly for small to medium-sized buildings. Waffle slabs, although more expensive upfront because of complex formwork and reinforcement, offer long-term savings via reduced material usage and enhanced load distribution for large spans. When comparing cost, flat slabs suit projects with tight budgets and moderate loads, while waffle slabs justify higher initial expenses with structural efficiency and durability benefits over time.

Common Applications in Modern Construction

Flat slabs are commonly applied in commercial buildings, parking garages, and residential towers due to their ease of installation, reduced floor-to-floor height, and flexibility in accommodating architectural features. Waffle slabs are preferred in large-span structures like auditoriums, sports arenas, and industrial warehouses because of their superior load distribution, high strength-to-weight ratio, and enhanced rigidity. Both slab systems optimize structural efficiency but serve distinct functional demands based on load requirements and architectural design.

Advantages and Disadvantages of Each Slab Type

Flat slabs offer faster construction and reduced formwork costs due to their simple flat surface, making them ideal for buildings with frequent column layouts; however, they may have limitations in spanning large areas without increased slab thickness or additional reinforcement. Waffle slabs provide superior load distribution and greater strength-to-weight ratio, allowing for longer spans with less concrete and improved structural efficiency, yet they require more complex formwork and longer construction times. Choosing between flat and waffle slabs depends on factors such as structural load requirements, budget constraints, architectural aesthetics, and construction timeline priorities.

Conclusion: Choosing the Right Slab for Your Project

Flat slabs offer simplified formwork and faster construction, ideal for buildings with moderate loads and straightforward layouts. Waffle slabs provide superior strength and load distribution, making them suitable for heavy loads and long spans in commercial or industrial structures. Selecting the appropriate slab depends on project-specific factors such as load requirements, architectural design, budget constraints, and construction timeline.

Flat slab Infographic

libterm.com

libterm.com