Shear deformation occurs when parallel layers within a material slide past one another due to applied forces, causing a change in shape without altering volume. This phenomenon is critical in understanding the behavior of materials under stress, especially in engineering and material science applications. Discover how shear deformation impacts material performance and why it matters for your projects in the rest of this article.

Table of Comparison

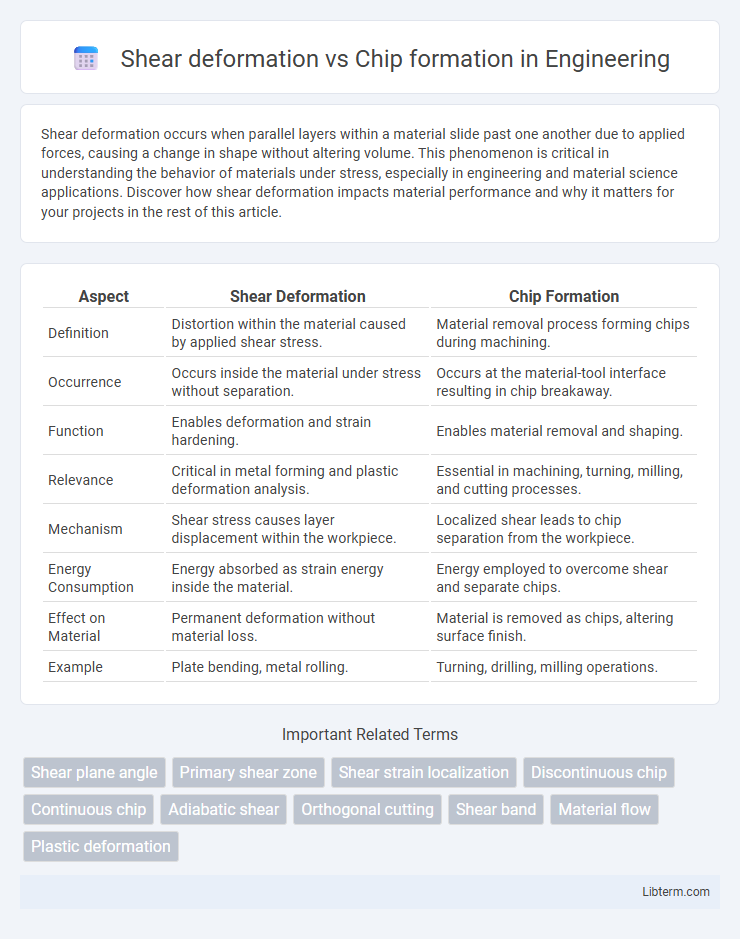

| Aspect | Shear Deformation | Chip Formation |

|---|---|---|

| Definition | Distortion within the material caused by applied shear stress. | Material removal process forming chips during machining. |

| Occurrence | Occurs inside the material under stress without separation. | Occurs at the material-tool interface resulting in chip breakaway. |

| Function | Enables deformation and strain hardening. | Enables material removal and shaping. |

| Relevance | Critical in metal forming and plastic deformation analysis. | Essential in machining, turning, milling, and cutting processes. |

| Mechanism | Shear stress causes layer displacement within the workpiece. | Localized shear leads to chip separation from the workpiece. |

| Energy Consumption | Energy absorbed as strain energy inside the material. | Energy employed to overcome shear and separate chips. |

| Effect on Material | Permanent deformation without material loss. | Material is removed as chips, altering surface finish. |

| Example | Plate bending, metal rolling. | Turning, drilling, milling operations. |

Introduction to Shear Deformation and Chip Formation

Shear deformation is the process where material layers slide over each other under applied stress, causing irreversible changes in shape without volume change. Chip formation occurs during machining, where shear deformation localizes ahead of the cutting tool, leading to the separation of material in the form of chips. Understanding the mechanics of shear deformation is crucial for optimizing chip formation, improving cutting efficiency, and reducing tool wear.

Fundamentals of Metal Cutting Mechanics

Shear deformation in metal cutting occurs within the primary shear zone where the material undergoes intense plastic deformation leading to chip formation, a key aspect of metal cutting mechanics. The chip formation mechanism involves separating the workpiece material along the shear plane, transforming it into a continuous, segmented, or discontinuous chip based on cutting conditions and material properties. Understanding the interaction between shear deformation and chip formation enhances prediction of cutting forces, tool wear, and surface finish in machining processes.

Shear Deformation: Definition and Principles

Shear deformation refers to the process where consecutive layers of material slide past each other under an applied force, resulting in a change in shape without volume alteration. It plays a critical role in chip formation during metal cutting, where intense shear deformation occurs along the shear plane, leading to material separation. Understanding shear deformation principles helps optimize machining parameters and improve surface finish by controlling the chip formation mechanism.

Chip Formation: Types and Mechanisms

Chip formation in machining occurs through distinct mechanisms primarily categorized as continuous, discontinuous, and serrated chips. Continuous chips form under ductile material conditions with stable cutting parameters, promoting smooth shear deformation along the shear plane. Discontinuous chips result from brittle material fracture or interrupted cutting, characterized by repeated shear failure, while serrated chips exhibit cyclic shear localization due to thermal and mechanical softening effects.

Comparative Analysis: Shear Deformation vs Chip Formation

Shear deformation involves the distortion of material layers due to applied forces, crucial in understanding metal cutting mechanics, whereas chip formation refers to the actual separation and removal of material from the workpiece. The comparative analysis highlights that shear deformation governs the initiation phase of chip formation, influencing chip morphology, size, and surface finish. Optimizing shear deformation parameters like shear angle and strain rate directly impacts chip formation efficiency, tool wear, and machining accuracy in manufacturing processes.

Factors Influencing Shear Deformation and Chip Formation

Shear deformation and chip formation during machining are significantly influenced by factors such as cutting speed, tool geometry, material properties, and friction at the tool-workpiece interface. Higher cutting speeds typically increase shear strain rates, affecting chip morphology and leading to continuous or segmented chips depending on material ductility. Tool rake angle and work material hardness alter shear zone characteristics, consequently impacting chip thickness and shape.

Effects on Surface Finish and Tool Wear

Shear deformation directly influences chip formation by controlling the strain and temperature in the shear zone, which affects the smoothness of the machined surface. Higher shear deformation typically leads to increased surface roughness and accelerated tool wear due to greater friction and heat generation. Optimizing shear deformation parameters results in improved surface finish and prolonged tool life by minimizing micro-cracks and reducing abrasive wear on cutting tools.

Experimental Methods for Studying Shear Deformation and Chip Formation

Experimental methods for studying shear deformation and chip formation include high-speed imaging, which captures real-time chip morphology and shear zone dynamics during machining processes. Microstructural analysis using scanning electron microscopy (SEM) and transmission electron microscopy (TEM) reveals grain distortion and strain localization within the shear zone, providing insights into deformation mechanisms. Instrumented cutting tests combined with force measurement and digital image correlation (DIC) techniques enable precise quantification of shear strain, strain rate, and chip segmentation patterns under varying cutting conditions.

Industrial Applications and Process Optimization

Shear deformation critically influences chip formation by determining the shape and size of chips produced in machining operations, directly impacting surface finish and tool wear in industrial applications. Optimizing shear deformation parameters--such as shear angle and strain rate--enhances cutting efficiency and reduces energy consumption in CNC milling, turning, and drilling processes. Advanced monitoring of shear zone characteristics facilitates improved process control and minimizes material waste, driving cost-effective and high-precision manufacturing outcomes.

Future Trends in Metal Cutting Research

Future trends in metal cutting research emphasize the integration of advanced modeling techniques to better predict shear deformation and chip formation dynamics at micro and nanoscale levels. Innovations in high-speed imaging and machine learning algorithms offer unprecedented insights into optimizing cutting parameters for reduced tool wear and improved surface quality. Sustainable manufacturing approaches are driving the development of adaptive control systems that minimize energy consumption while enhancing chip morphology control in real-time.

Shear deformation Infographic

libterm.com

libterm.com