Effective vibration control minimizes noise and structural damage by using dampers, isolators, and absorbers tailored to specific environments. It enhances equipment lifespan and improves overall safety and comfort in industrial and residential settings. Discover practical strategies and technologies for optimizing vibration control in the rest of this article.

Table of Comparison

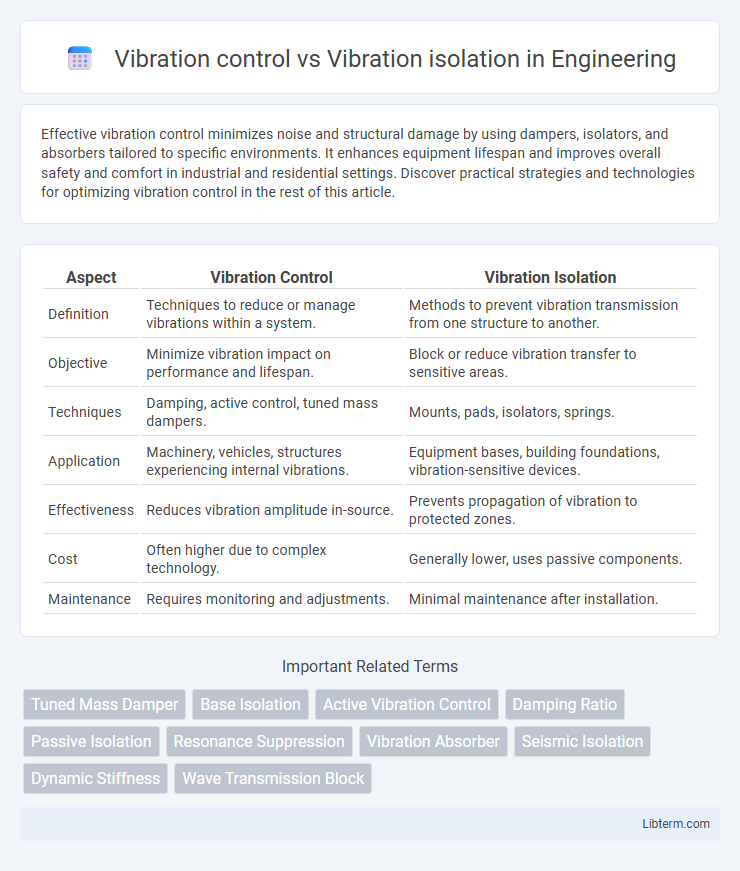

| Aspect | Vibration Control | Vibration Isolation |

|---|---|---|

| Definition | Techniques to reduce or manage vibrations within a system. | Methods to prevent vibration transmission from one structure to another. |

| Objective | Minimize vibration impact on performance and lifespan. | Block or reduce vibration transfer to sensitive areas. |

| Techniques | Damping, active control, tuned mass dampers. | Mounts, pads, isolators, springs. |

| Application | Machinery, vehicles, structures experiencing internal vibrations. | Equipment bases, building foundations, vibration-sensitive devices. |

| Effectiveness | Reduces vibration amplitude in-source. | Prevents propagation of vibration to protected zones. |

| Cost | Often higher due to complex technology. | Generally lower, uses passive components. |

| Maintenance | Requires monitoring and adjustments. | Minimal maintenance after installation. |

Introduction to Vibration Management

Vibration control involves techniques and devices designed to reduce the amplitude of vibrations in machinery and structures, enhancing performance and longevity. Vibration isolation focuses on preventing the transmission of vibrations from a source to sensitive equipment or areas by using isolators such as springs, dampers, or mounts. Both approaches are essential components of vibration management, aiming to improve operational efficiency and safety in various industrial applications.

Defining Vibration Control

Vibration control involves actively managing and reducing vibrations within a system through techniques such as damping, tuning, and active feedback mechanisms to minimize their impact on performance and structural integrity. Unlike vibration isolation, which aims to prevent vibration transfer by physically separating components using mounts or pads, vibration control targets the source or path of vibrations to diminish their amplitude. Effective vibration control enhances equipment longevity and operational precision by addressing vibrations at their origin or during propagation.

Understanding Vibration Isolation

Vibration isolation involves reducing the transmission of vibrations from a source to a sensitive structure or equipment by introducing materials or systems that absorb or block vibrational energy. This technique is essential in protecting machines, buildings, and instruments from harmful vibrations that can cause damage or reduce performance. Effective vibration isolation relies on selecting appropriate isolators like pads, springs, or dampers tailored to the frequency and amplitude of the vibrations encountered.

Key Differences: Vibration Control vs Vibration Isolation

Vibration control involves actively or passively reducing unwanted vibrations within a system to minimize their amplitude and impact on performance, often using dampers or tuned mass absorbers. Vibration isolation focuses on preventing the transmission of vibrations from one part of a structure to another, typically through the use of isolators such as springs, elastomers, or mounts that absorb and block vibrational energy. The key difference lies in vibration control aiming to suppress vibrations internally, while vibration isolation aims to separate and protect components from external vibration sources.

Common Applications of Vibration Control

Vibration control techniques are widely used in industrial machinery, automotive systems, and building structures to reduce unwanted oscillations and enhance equipment lifespan. Common applications include damping vibrations in HVAC systems, minimizing seismic impacts on bridges, and controlling noise and vibrations in precision manufacturing. Effective vibration control improves operational stability and prevents mechanical failures in various engineering fields.

Where Vibration Isolation Excels

Vibration isolation excels in preventing the transmission of vibrations from one structure or equipment to another, particularly in sensitive environments such as laboratories, precision manufacturing, and medical facilities. It effectively minimizes the impact of external vibrations on critical machinery, ensuring accuracy and longevity by isolating the source rather than merely controlling the vibration amplitude. This method outperforms vibration control when the goal is to protect delicate instruments from external disturbances rather than reducing vibrations within a single system.

Technologies and Methods Used

Vibration control technologies primarily include active systems using sensors and actuators that counteract vibrations in real-time, as well as passive methods such as tuned mass dampers and viscoelastic materials designed to absorb energy. Vibration isolation relies on devices like springs, rubber mounts, and air bearings to physically separate sensitive equipment from vibration sources, reducing transmission through structural decoupling. Advanced methods combine smart materials and adaptive algorithms to optimize both vibration control and isolation in industrial and structural applications.

Advantages and Limitations of Each Approach

Vibration control reduces unwanted motion by actively altering system dynamics through feedback mechanisms, improving precision in sensitive equipment but often requiring complex design and higher costs. Vibration isolation prevents transmission of vibrations by physically decoupling systems using materials or devices like mounts and pads, offering simplicity and cost-effectiveness but limited effectiveness at low frequencies. The choice depends on application-specific frequency ranges, precision requirements, and budget constraints, with control suited for dynamic adaptability and isolation preferred for passive, maintenance-free operation.

Choosing the Right Solution for Your Needs

Vibration control involves reducing or eliminating vibrations through damping, absorption, or active control methods, whereas vibration isolation aims to prevent vibrations from transferring between structures using isolators or mounts. Choosing the right solution depends on factors such as the frequency and amplitude of vibrations, the sensitivity of equipment, and environmental conditions. Understanding application-specific requirements and cost-effectiveness ensures optimal performance and longevity of machinery or structures.

Future Trends in Vibration Management

Future trends in vibration management emphasize advanced materials and smart technologies for both vibration control and vibration isolation. Smart sensors, adaptive control systems, and machine learning algorithms enable real-time monitoring and adjustment, enhancing the efficiency of vibration mitigation in industries such as aerospace, automotive, and manufacturing. Integration of nanomaterials and metamaterials promises improved vibration damping and isolation properties, driving innovation in next-generation vibration management solutions.

Vibration control Infographic

libterm.com

libterm.com