A screw compressor uses two intermeshing helical rotors to compress gas efficiently and quietly, often found in industrial applications requiring reliable airflow. This technology offers high energy efficiency and low maintenance compared to traditional piston compressors, making it an excellent choice for continuous operation. Discover how a screw compressor can optimize Your system's performance by exploring the detailed insights in the rest of this article.

Table of Comparison

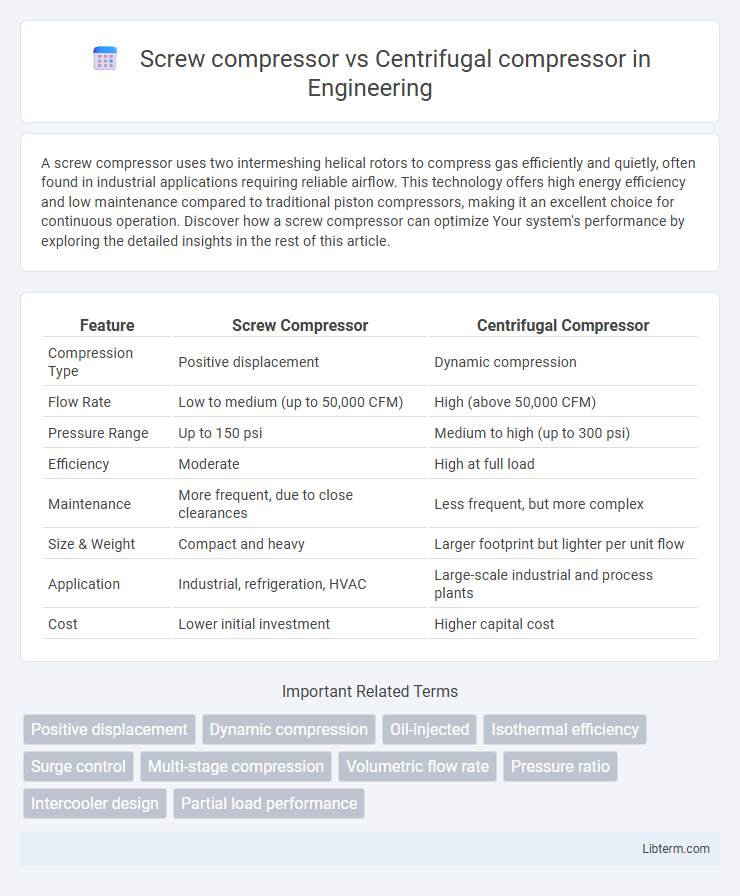

| Feature | Screw Compressor | Centrifugal Compressor |

|---|---|---|

| Compression Type | Positive displacement | Dynamic compression |

| Flow Rate | Low to medium (up to 50,000 CFM) | High (above 50,000 CFM) |

| Pressure Range | Up to 150 psi | Medium to high (up to 300 psi) |

| Efficiency | Moderate | High at full load |

| Maintenance | More frequent, due to close clearances | Less frequent, but more complex |

| Size & Weight | Compact and heavy | Larger footprint but lighter per unit flow |

| Application | Industrial, refrigeration, HVAC | Large-scale industrial and process plants |

| Cost | Lower initial investment | Higher capital cost |

Introduction to Screw and Centrifugal Compressors

Screw compressors use meshing helical rotors to compress gases efficiently in low to medium pressure applications, providing steady flow and high reliability. Centrifugal compressors rely on high-speed impellers to impart kinetic energy to gases, achieving compression primarily in large-scale, high-capacity industrial systems. Both types optimize performance through distinct mechanisms suited to specific pressure ranges and operational demands.

Basic Working Principles

Screw compressors operate using two meshing helical rotors to compress gas by trapping and reducing its volume within the rotor cavities. Centrifugal compressors increase gas velocity through a rotating impeller and convert this velocity into pressure via a diffuser. The fundamental difference lies in the volumetric displacement of screw compressors versus the dynamic compression through kinetic energy conversion in centrifugal compressors.

Key Differences in Design

Screw compressors utilize meshing helical rotors to compress gas in a positive displacement manner, offering consistent pressure ratios and compact design ideal for low to medium pressure applications. Centrifugal compressors rely on high-speed rotating impellers to impart kinetic energy to the gas, which is then converted to pressure through diffusion, making them suitable for high flow rates and continuous process environments. The fundamental design difference impacts efficiency, maintenance complexity, and operational scope, with screw compressors favored for oil-free or lubrication applications and centrifugal compressors excelling in large-scale industrial gas compression.

Efficiency Comparison

Screw compressors generally offer higher efficiency at low to medium pressure ranges due to their positive displacement mechanism, making them ideal for consistent, moderate flow applications. Centrifugal compressors achieve superior efficiency at high flow rates and pressure ratios by utilizing dynamic compression through high-speed impellers, which reduces energy losses in large-scale industrial processes. Efficiency in screw compressors tends to decline with increasing pressure, whereas centrifugal compressors maintain or improve efficiency at higher pressures, highlighting a key distinction in their performance profiles.

Maintenance and Reliability

Screw compressors generally offer easier maintenance due to their simpler design and fewer moving parts, which leads to reduced downtime and lower repair costs. Centrifugal compressors demand more specialized servicing and precise alignment, increasing maintenance complexity but are highly reliable in continuous, high-capacity industrial applications. Both compressor types require regular monitoring of lubrication and vibration levels to maintain optimal performance and extend equipment lifespan.

Applications and Industry Usage

Screw compressors are widely used in industries requiring moderate pressure and continuous operation, such as HVAC systems, refrigeration, and manufacturing processes involving pneumatic tools and air injection. Centrifugal compressors dominate in large-scale applications demanding high flow rates and efficiency, including oil and gas processing, power generation, and chemical plants. The choice between screw and centrifugal compressors depends on factors like desired pressure, volumetric flow rate, and operational stability in sectors like automotive, aerospace, and petrochemical industries.

Energy Consumption and Operating Costs

Screw compressors typically consume more energy at part load due to sliding vanes and internal leakage, while centrifugal compressors offer higher efficiency and lower energy consumption at large-scale, continuous operations because of their dynamic compression mechanism. Operating costs for screw compressors tend to be higher owing to more frequent maintenance and wear on rotors, whereas centrifugal compressors benefit from fewer moving parts and longer intervals between maintenance, reducing overall operating expenses. Selecting the right compressor depends on application size, with centrifugal compressors favored for high-capacity, energy-sensitive environments and screw compressors suited for variable-load scenarios.

Advantages of Screw Compressors

Screw compressors offer superior energy efficiency and consistent performance at varying loads compared to centrifugal compressors, making them ideal for applications with fluctuating demand. Their compact design and fewer moving parts result in lower maintenance costs and increased reliability in industrial environments. Screw compressors also provide better air quality with minimal pulsation and smoother airflow, enhancing system stability and equipment lifespan.

Advantages of Centrifugal Compressors

Centrifugal compressors offer high efficiency and consistent performance at large volumes, making them ideal for industrial applications requiring continuous operation. Their compact design supports lower maintenance costs and longer service life compared to screw compressors. High-pressure ratios and the ability to handle variable flow rates enhance their versatility in gas processing and power generation sectors.

Conclusion: Choosing the Right Compressor

Selecting the right compressor depends on the application requirements, with screw compressors excelling in low to medium pressure, oil-free air delivery, and compact installations, while centrifugal compressors offer superior efficiency and capacity for high flow and high-pressure operations. Industrial processes demanding continuous, high-volume airflow benefit from centrifugal compressors, whereas screw compressors are preferable for operations with variable load and quieter performance needs. Assessing factors such as pressure range, maintenance, energy efficiency, and space availability is essential for optimal compressor selection.

Screw compressor Infographic

libterm.com

libterm.com