Edge contact technology enhances electrical connections by optimizing the interface between components, resulting in improved signal integrity and reduced resistance. This method is widely used in advanced electronics to ensure reliable performance and durability under high stress conditions. Discover how edge contact can transform your device's connectivity by reading the rest of this article.

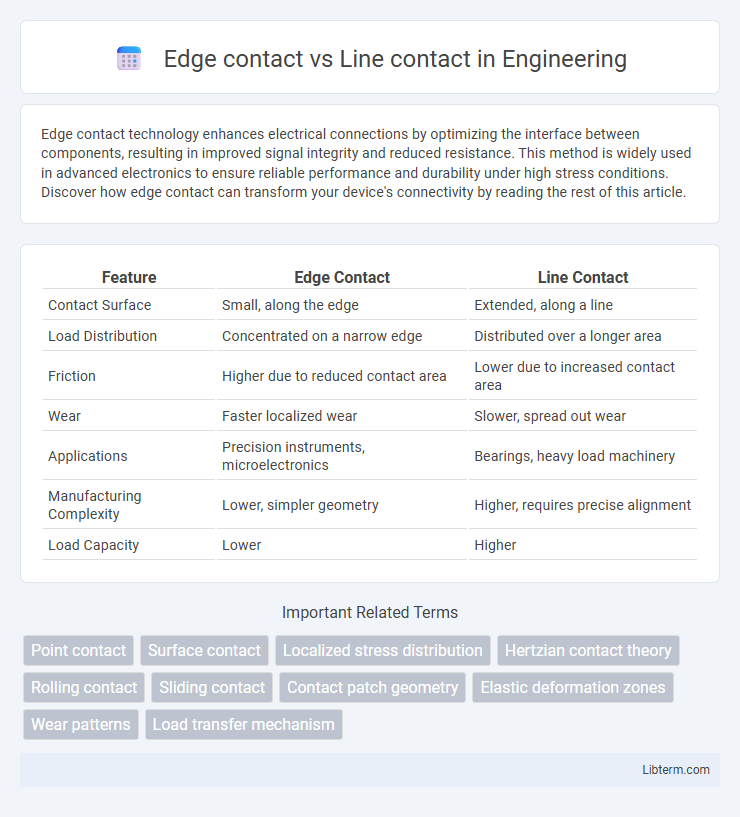

Table of Comparison

| Feature | Edge Contact | Line Contact |

|---|---|---|

| Contact Surface | Small, along the edge | Extended, along a line |

| Load Distribution | Concentrated on a narrow edge | Distributed over a longer area |

| Friction | Higher due to reduced contact area | Lower due to increased contact area |

| Wear | Faster localized wear | Slower, spread out wear |

| Applications | Precision instruments, microelectronics | Bearings, heavy load machinery |

| Manufacturing Complexity | Lower, simpler geometry | Higher, requires precise alignment |

| Load Capacity | Lower | Higher |

Introduction to Edge and Line Contact

Edge contact occurs when two components meet along a line or narrow surface, creating a concentrated area of interaction that transmits forces primarily along that edge. Line contact involves surfaces touching along a length, providing a linear distribution of load that enhances stability and reduces localized stress compared to point contact. Understanding the distinction between edge and line contact is crucial for designing mechanical interfaces that optimize load distribution and minimize wear.

Defining Edge Contact: Key Characteristics

Edge contact refers to the specific interface where two surfaces meet along a narrow line or sharp ridge rather than over a broad, flat area, concentrating applied forces onto a minimal contact width. Key characteristics include higher localized stress distribution, increased pressure per unit area, and a propensity for wear or deformation due to the concentrated load. This contact type is critical in precision mechanics and bearing design where alignment and load capacity depend on controlled, minimal contact regions.

Understanding Line Contact: Essential Features

Line contact involves the interaction where two cylindrical surfaces touch along a continuous line, providing a larger contact area compared to edge contact. This type of contact enhances load distribution, reduces contact stress, and improves durability in mechanical components such as bearings and gears. Understanding line contact is essential for optimizing design parameters like contact pressure and lubrication, ensuring efficient performance and longer service life in engineering applications.

Mechanical Performance Comparison

Edge contact bearings offer higher stiffness and better load distribution due to the increased contact area along the bearing edge, resulting in improved resistance to deformation under heavy loads. Line contact bearings provide superior alignment precision and reduced friction by concentrating the load along a narrow contact line, enhancing rotational accuracy and minimizing wear. Mechanical performance differences impact application choices, with edge contact preferred for high load and rigidity requirements, while line contact suits high-speed, low-friction environments.

Load Distribution Differences

Edge contact concentrates load along a narrow line, resulting in high contact stress and potential deformation in the contacting surfaces. Line contact distributes load over a longer linear area, reducing localized stress and enhancing durability by spreading forces more evenly. Bearings with line contact typically exhibit better load distribution characteristics, leading to improved performance under heavy loads.

Applications in Industry

Edge contact provides higher load capacity and better alignment in heavy-duty machinery such as gearboxes and turbines, making it ideal for industrial applications with high radial and axial loads. Line contact distributes stress over a larger area, improving durability and reducing wear in applications like automotive transmissions and conveyors where consistent load distribution and smooth motion are critical. Both contact types enhance performance in specific industrial environments by optimizing bearing life and operational efficiency.

Advantages of Edge Contact

Edge contact provides superior electrical conductivity and mechanical stability compared to line contact by maximizing the contact area between surfaces. This increased interface enhances current density distribution, reducing resistance and heat generation in electronic components. The robust contact design in edge contact applications also improves durability and long-term performance under high stress or thermal cycling conditions.

Benefits of Line Contact

Line contact offers increased load distribution and enhanced rigidity compared to edge contact, resulting in better stability under high radial and axial loads. The continuous contact along a line reduces stress concentration, improving bearing durability and performance in demanding applications. This makes line contact ideal for precision machinery requiring consistent alignment and resistance to deformation.

Challenges and Limitations

Edge contact often faces challenges such as uneven pressure distribution leading to increased wear and reduced electrical reliability, limiting its effectiveness in high-frequency applications. Line contact, while providing better load distribution and improved conductivity, is constrained by the complexity of manufacturing precise geometric alignments and susceptibility to misalignment under mechanical stress. Both contact types encounter limitations related to material fatigue and thermal expansion, impacting long-term durability and performance.

Choosing Between Edge and Line Contact

Choosing between edge contact and line contact depends on the application's load distribution and precision requirements. Edge contact offers higher load capacity and rigidity, making it ideal for heavy-duty applications and increased resistance to misalignment. Line contact provides smoother motion and better alignment accuracy, suitable for high-speed, low-load environments demanding precise positioning.

Edge contact Infographic

libterm.com

libterm.com