Analytical modeling transforms complex data into clear, actionable insights by applying mathematical techniques and algorithms. It enables you to predict outcomes, optimize processes, and support strategic decision-making across various industries. Explore the rest of this article to uncover the key benefits and applications of analytical modeling in your field.

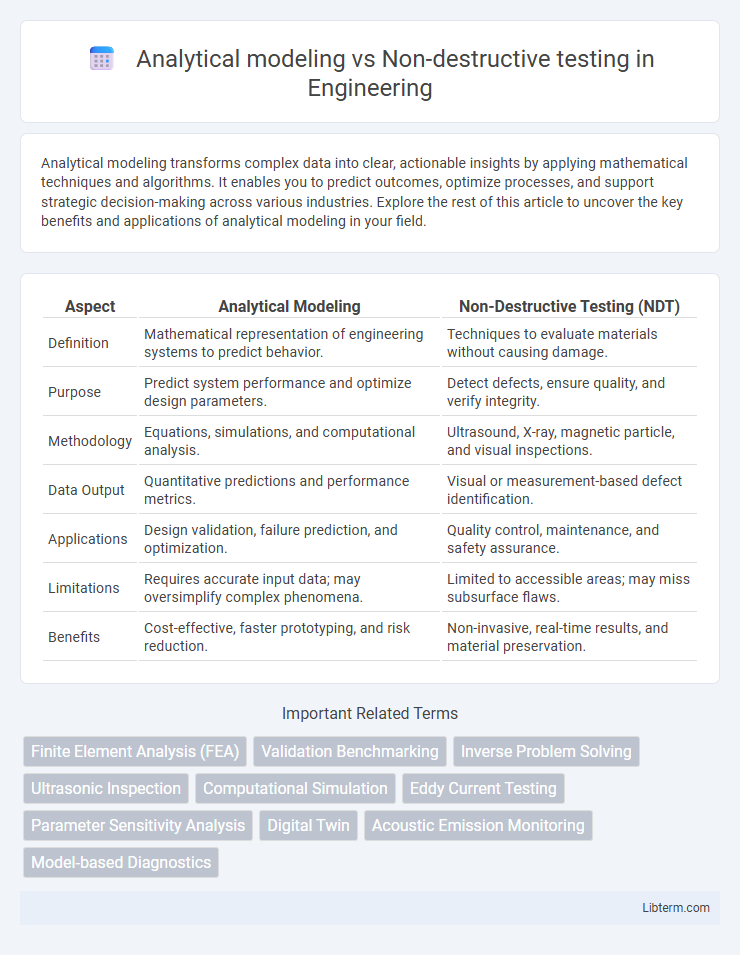

Table of Comparison

| Aspect | Analytical Modeling | Non-Destructive Testing (NDT) |

|---|---|---|

| Definition | Mathematical representation of engineering systems to predict behavior. | Techniques to evaluate materials without causing damage. |

| Purpose | Predict system performance and optimize design parameters. | Detect defects, ensure quality, and verify integrity. |

| Methodology | Equations, simulations, and computational analysis. | Ultrasound, X-ray, magnetic particle, and visual inspections. |

| Data Output | Quantitative predictions and performance metrics. | Visual or measurement-based defect identification. |

| Applications | Design validation, failure prediction, and optimization. | Quality control, maintenance, and safety assurance. |

| Limitations | Requires accurate input data; may oversimplify complex phenomena. | Limited to accessible areas; may miss subsurface flaws. |

| Benefits | Cost-effective, faster prototyping, and risk reduction. | Non-invasive, real-time results, and material preservation. |

Introduction to Analytical Modeling and Non-Destructive Testing

Analytical modeling utilizes mathematical frameworks and simulations to predict material behavior and structural performance without physical alteration, enhancing design accuracy and efficiency. Non-destructive testing (NDT) employs techniques such as ultrasonic, radiographic, and magnetic particle inspection to evaluate the integrity of materials and components without causing damage. Combining analytical modeling with NDT enables comprehensive assessment by correlating predictive data with empirical inspection results, optimizing maintenance and quality control processes.

Understanding Analytical Modeling: Principles and Applications

Analytical modeling employs mathematical equations and algorithms to simulate physical systems, enabling precise predictions of behavior under various conditions. It is widely used in engineering fields to design and optimize components without physical prototyping, thereby saving time and costs. Applications span structural analysis, thermal dynamics, and fluid mechanics, providing deep insights into system performance that complement empirical methods like non-destructive testing.

Overview of Non-Destructive Testing Techniques

Non-destructive testing (NDT) techniques enable the evaluation of material properties or structural integrity without causing damage. Common NDT methods include ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing, each utilizing different physical principles to detect flaws. These techniques are essential in industries such as aerospace, manufacturing, and construction for ensuring safety and quality control.

Key Differences Between Analytical Modeling and Non-Destructive Testing

Analytical modeling relies on mathematical equations and simulations to predict the behavior and properties of materials or systems under various conditions, emphasizing theoretical analysis and computational accuracy. Non-destructive testing (NDT) involves empirical techniques such as ultrasonic, radiographic, or magnetic inspections to detect internal defects or abnormalities without causing damage to the specimen. Key differences include the predictive nature and virtual environment of analytical modeling versus the physical inspection and real-time defect detection in non-destructive testing.

Advantages of Analytical Modeling in Structural Analysis

Analytical modeling in structural analysis provides precise mathematical representations of complex structures, enabling accurate prediction of stress, strain, and deformation under various load conditions. This method facilitates optimization of material usage and design parameters, resulting in cost-effective and safer structures. Compared to non-destructive testing, analytical modeling allows for early detection of potential structural failures without the need for physical inspection, thereby reducing downtime and maintenance costs.

Benefits of Non-Destructive Testing for Material Evaluation

Non-destructive testing (NDT) offers critical benefits for material evaluation by preserving the integrity of the tested components, allowing repeated inspections without causing damage. NDT techniques like ultrasonic testing, radiography, and eddy current testing provide accurate detection of internal defects, corrosion, and structural flaws, enhancing safety and reliability. The ability to perform in-situ inspections reduces downtime and maintenance costs compared to analytical modeling, which primarily relies on theoretical predictions without physical testing.

Limitations of Analytical Modeling Methods

Analytical modeling methods face limitations in accurately capturing complex material behaviors and heterogeneous structures, leading to potential discrepancies between predicted and real-world performance. These models often rely on simplifying assumptions and idealized conditions, which reduce their applicability in diverse industrial scenarios. Non-destructive testing complements analytical modeling by providing empirical data that validate and refine theoretical predictions.

Challenges Associated with Non-Destructive Testing

Non-destructive testing (NDT) faces challenges such as difficulty detecting subsurface defects and limitations in accurately characterizing material properties compared to analytical modeling. Variability in operator skill and environmental conditions can lead to inconsistent results and interpretation errors. Furthermore, NDT methods often require extensive calibration and may struggle with complex geometries, reducing reliability in critical applications.

Integration of Analytical Modeling and Non-Destructive Testing

The integration of analytical modeling and non-destructive testing (NDT) enhances the accuracy and reliability of material and structural assessments by combining predictive simulations with real-time inspection data. Analytical models can simulate stress, strain, and failure patterns while NDT methods such as ultrasonic, radiographic, or eddy current testing provide critical validation and calibration of these models, enabling early detection of flaws without damaging the asset. This synergistic approach improves maintenance planning, reduces downtime, and extends the lifespan of critical components in industries like aerospace, manufacturing, and civil infrastructure.

Future Trends in Analytical Modeling and Non-Destructive Testing

Future trends in analytical modeling emphasize the integration of artificial intelligence and machine learning to enhance predictive accuracy and decision-making in material assessment. Non-destructive testing is advancing through the adoption of digital twins and real-time sensor data analytics, facilitating continuous monitoring and early fault detection. These innovations are driving more efficient maintenance strategies and extending the lifecycle of critical infrastructure.

Analytical modeling Infographic

libterm.com

libterm.com