Peak cylinder pressure is the highest pressure reached inside an engine's combustion chamber during the power stroke, directly influencing engine efficiency and performance. Excessively high peak pressure can lead to engine knocking and mechanical stress, while optimal pressure enhances fuel combustion and power output. Discover how managing peak cylinder pressure can improve your engine's longevity and efficiency by exploring the full article.

Table of Comparison

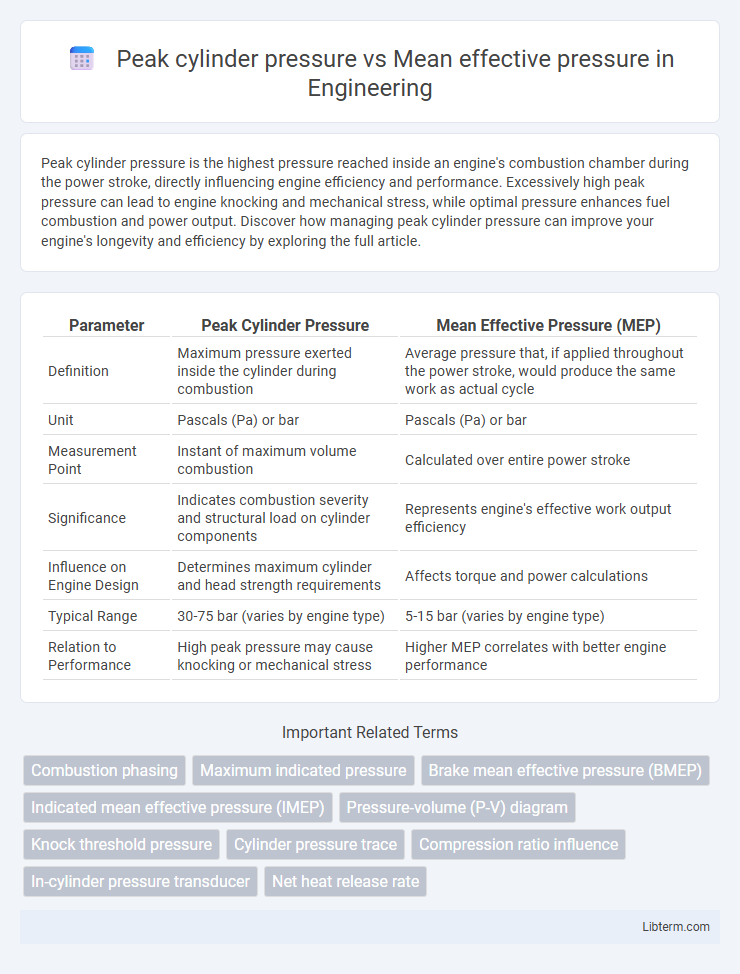

| Parameter | Peak Cylinder Pressure | Mean Effective Pressure (MEP) |

|---|---|---|

| Definition | Maximum pressure exerted inside the cylinder during combustion | Average pressure that, if applied throughout the power stroke, would produce the same work as actual cycle |

| Unit | Pascals (Pa) or bar | Pascals (Pa) or bar |

| Measurement Point | Instant of maximum volume combustion | Calculated over entire power stroke |

| Significance | Indicates combustion severity and structural load on cylinder components | Represents engine's effective work output efficiency |

| Influence on Engine Design | Determines maximum cylinder and head strength requirements | Affects torque and power calculations |

| Typical Range | 30-75 bar (varies by engine type) | 5-15 bar (varies by engine type) |

| Relation to Performance | High peak pressure may cause knocking or mechanical stress | Higher MEP correlates with better engine performance |

Introduction to Cylinder Pressure in Engines

Cylinder pressure in engines is a critical parameter that influences performance, combustion efficiency, and emissions. Peak cylinder pressure represents the maximum pressure achieved during combustion, directly affecting mechanical stress on engine components. Mean effective pressure (MEP) is an averaged value that reflects the engine's ability to convert fuel energy into mechanical work, serving as a key indicator of engine efficiency and power output.

Defining Peak Cylinder Pressure

Peak cylinder pressure defines the maximum pressure within the combustion chamber during the power stroke, critical for engine performance and durability assessments. Mean effective pressure (MEP) represents the average pressure applied on the piston over the entire power stroke, serving as an efficiency metric for engines. Comparing peak cylinder pressure to MEP highlights the intensity and distribution of combustion forces impacting engine components.

Understanding Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) is a critical parameter representing the average pressure applied on the piston during the combustion cycle, providing a direct measure of an engine's efficiency and work output. Unlike Peak Cylinder Pressure, which denotes the maximum pressure at a specific moment, MEP correlates to the engine's overall performance by averaging pressure over the entire stroke duration. Understanding MEP aids in comparing different engine designs and operating conditions, as it directly relates to torque and power calculations independent of engine size or speed.

Significance of Peak Cylinder Pressure in Engine Performance

Peak cylinder pressure directly influences engine performance by indicating the maximum stress and combustion efficiency within the cylinder, affecting power output and durability. This parameter is critical for optimizing ignition timing and fuel-air mixture to prevent knocking and ensure smooth engine operation. Understanding peak cylinder pressure helps engineers enhance thermal efficiency and maximize mean effective pressure, leading to improved overall engine performance.

Role of Mean Effective Pressure in Power Output

Mean effective pressure (MEP) serves as a critical indicator of an engine's ability to convert combustion pressure into usable power, directly correlating with engine torque and overall efficiency. While peak cylinder pressure measures the maximum pressure inside the combustion chamber, MEP provides a more consistent representation of the average pressure acting on the piston during the power stroke, making it essential for evaluating engine performance. Optimizing MEP through efficient combustion and proper timing enhances power output and fuel economy more effectively than focusing solely on peak cylinder pressure.

Key Differences: Peak Cylinder Pressure vs. Mean Effective Pressure

Peak cylinder pressure represents the maximum instantaneous pressure inside the combustion chamber during the combustion cycle, directly influencing engine stress and performance limits. Mean effective pressure (MEP) is an averaged value of the pressure that reflects the engine's overall efficiency and work output per cycle, calculated over the entire power stroke. While peak cylinder pressure affects the mechanical design and durability, mean effective pressure serves as a more comprehensive indicator of engine power and thermal efficiency.

Effects on Engine Design and Durability

Peak cylinder pressure directly influences engine structural design, requiring robust materials and reinforced components to withstand high stress and avoid failure. Mean effective pressure affects overall engine performance and thermal efficiency, guiding decisions on combustion chamber shape and fuel injection strategies. Balancing high peak cylinder pressures with optimized mean effective pressure is crucial for enhancing engine durability while maintaining power output.

Implications for Fuel Efficiency and Emissions

Peak cylinder pressure directly influences the combustion efficiency and knock tendency in an engine, affecting optimal ignition timing and fuel-air mixture quality. Mean effective pressure (MEP) reflects the engine's overall work output and correlates with fuel consumption and emissions levels. Higher peak cylinder pressures combined with optimized MEP can improve fuel efficiency by enhancing combustion completeness but require advanced engine control strategies to minimize NOx emissions and avoid engine damage.

Measurement Techniques for Cylinder Pressure

Peak cylinder pressure and mean effective pressure are critical parameters in engine performance analysis, measured using high-precision piezoelectric pressure sensors installed in the combustion chamber. Advanced signal processing techniques, such as crank angle-based data acquisition and filtering algorithms, enhance the accuracy of pressure traces for both peak pressures and mean effective pressure calculations. These measurements enable the precise evaluation of combustion efficiency and engine load conditions, facilitating optimized engine tuning and diagnostics.

Optimizing Engine Performance: Balancing Peak Pressure and MEP

Optimizing engine performance requires balancing peak cylinder pressure and mean effective pressure (MEP) to maximize power output while ensuring mechanical reliability and fuel efficiency. High peak cylinder pressure increases combustion efficiency and power density but raises stress on engine components, whereas MEP provides a stable measure of average engine work output, guiding calibration for consistent performance. Effective tuning adjusts ignition timing, fuel-air mixture, and boost levels to achieve an optimal trade-off between these pressures, enhancing overall engine durability and efficiency.

Peak cylinder pressure Infographic

libterm.com

libterm.com