Visual inspection is a crucial method for identifying defects and ensuring quality in various industries by carefully examining materials, products, or structures without causing damage. This technique helps detect surface imperfections, misalignments, or wear and tear, contributing to effective maintenance and safety protocols. Explore this article to learn how visual inspection can enhance your operational efficiency and product reliability.

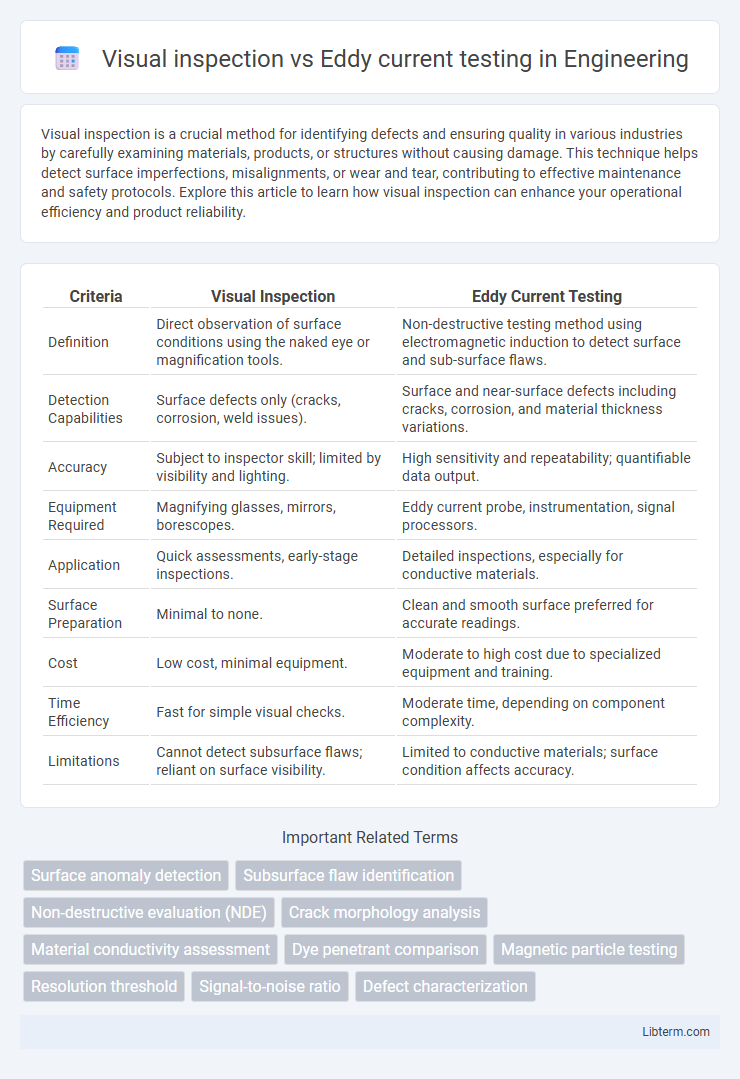

Table of Comparison

| Criteria | Visual Inspection | Eddy Current Testing |

|---|---|---|

| Definition | Direct observation of surface conditions using the naked eye or magnification tools. | Non-destructive testing method using electromagnetic induction to detect surface and sub-surface flaws. |

| Detection Capabilities | Surface defects only (cracks, corrosion, weld issues). | Surface and near-surface defects including cracks, corrosion, and material thickness variations. |

| Accuracy | Subject to inspector skill; limited by visibility and lighting. | High sensitivity and repeatability; quantifiable data output. |

| Equipment Required | Magnifying glasses, mirrors, borescopes. | Eddy current probe, instrumentation, signal processors. |

| Application | Quick assessments, early-stage inspections. | Detailed inspections, especially for conductive materials. |

| Surface Preparation | Minimal to none. | Clean and smooth surface preferred for accurate readings. |

| Cost | Low cost, minimal equipment. | Moderate to high cost due to specialized equipment and training. |

| Time Efficiency | Fast for simple visual checks. | Moderate time, depending on component complexity. |

| Limitations | Cannot detect subsurface flaws; reliant on surface visibility. | Limited to conductive materials; surface condition affects accuracy. |

Introduction to Non-Destructive Testing Methods

Visual inspection and eddy current testing are fundamental non-destructive testing (NDT) methods used to evaluate the integrity of materials without causing damage. Visual inspection relies on direct observation to identify surface defects, corrosion, or cracks, offering a quick and cost-effective assessment. Eddy current testing employs electromagnetic induction to detect subsurface flaws and material thickness variations, providing higher sensitivity for conductive materials in aerospace and manufacturing industries.

What is Visual Inspection?

Visual inspection is a non-destructive testing method that involves examining surfaces or components for defects, corrosion, cracks, or other anomalies using the naked eye or magnification tools. It relies on the inspector's skill to identify visible irregularities and is often the first step in quality control and maintenance processes. Compared to Eddy current testing, which detects subsurface flaws using electromagnetic fields, visual inspection is limited to surface evaluations but is quick and cost-effective for initial assessments.

What is Eddy Current Testing?

Eddy Current Testing (ECT) is a non-destructive testing method that uses electromagnetic induction to detect surface and near-surface defects in conductive materials. It involves generating eddy currents in the test object through an alternating magnetic field and measuring changes in these currents caused by flaws or material variations. ECT is highly effective for detecting cracks, corrosion, and other discontinuities without requiring contact or surface preparation, making it a valuable technique compared to visual inspection.

Key Principles of Visual Inspection

Visual inspection relies on the direct observation of surfaces using the naked eye or optical aids to identify defects such as cracks, corrosion, and surface irregularities. It is based on the key principles of accurate lighting, proper angle of view, and consistent scanning patterns to ensure thorough examination. This non-destructive method is essential for detecting visible anomalies before employing advanced techniques like eddy current testing for subsurface flaw detection.

Core Principles of Eddy Current Testing

Eddy current testing operates on the core principle of electromagnetic induction, where an alternating current in a coil generates a magnetic field that induces eddy currents in a conductive material. Variations in these eddy currents, caused by flaws or changes in material properties, affect the coil's impedance and enable defect detection. Visual inspection relies on surface observation and cannot detect subsurface defects, making eddy current testing essential for non-destructive evaluation of conductivity and structural integrity.

Advantages of Visual Inspection

Visual inspection offers immediate detection of surface defects such as cracks, corrosion, and deformations without requiring complex equipment or extensive training. It provides a cost-effective and efficient method for routine maintenance and initial assessments, enabling quick decisions for further testing or repairs. Unlike Eddy current testing, visual inspection does not depend on electromagnetic properties, making it versatile across various materials and surface conditions.

Benefits of Eddy Current Testing

Eddy current testing provides precise detection of surface and near-surface defects in conductive materials, offering higher sensitivity than visual inspection. It enables rapid, non-contact evaluation without requiring direct access or surface cleaning, reducing downtime and maintenance costs. The method also allows for accurate thickness measurements and flaw characterization, enhancing preventive maintenance and safety in critical industries like aerospace and manufacturing.

Limitations of Visual Inspection

Visual inspection is limited by its reliance on surface-level examination, making it ineffective for detecting subsurface defects or internal flaws in materials. It cannot quantify defect size or depth accurately, which reduces reliability in critical applications requiring precise assessment. Environmental factors such as lighting conditions and human error further constrain its effectiveness compared to nondestructive testing methods like Eddy current testing that utilize electromagnetic principles for enhanced defect detection.

Drawbacks of Eddy Current Testing

Eddy current testing is limited by its shallow penetration depth, making it unsuitable for detecting defects located deep within conductive materials. The method requires clean, smooth surfaces to ensure accurate results, as surface roughness and coatings can interfere with signal interpretation. Additionally, the testing is highly sensitive to material properties such as conductivity and permeability, which can complicate defect detection in complex or heterogeneous materials.

Visual Inspection vs Eddy Current Testing: Direct Comparison

Visual inspection provides a straightforward, cost-effective method for detecting surface defects, corrosion, and cracks, relying primarily on human observation and optical tools. Eddy current testing offers a more advanced, non-destructive technique capable of identifying both surface and subsurface flaws through electromagnetic induction, with higher sensitivity and accuracy in conductive materials. While visual inspection excels in simplicity and immediate feedback, eddy current testing delivers depth information and quantitative data essential for comprehensive defect analysis and preventive maintenance.

Visual inspection Infographic

libterm.com

libterm.com