A brazed joint forms when two metal surfaces are joined by melting a filler metal with a lower melting point than the base metals, creating a strong, durable bond without melting the base materials. This technique is widely used in plumbing, electronics, and automotive industries for its ability to create leak-proof, corrosion-resistant connections. Discover how brazed joints can enhance your projects by exploring the full article.

Table of Comparison

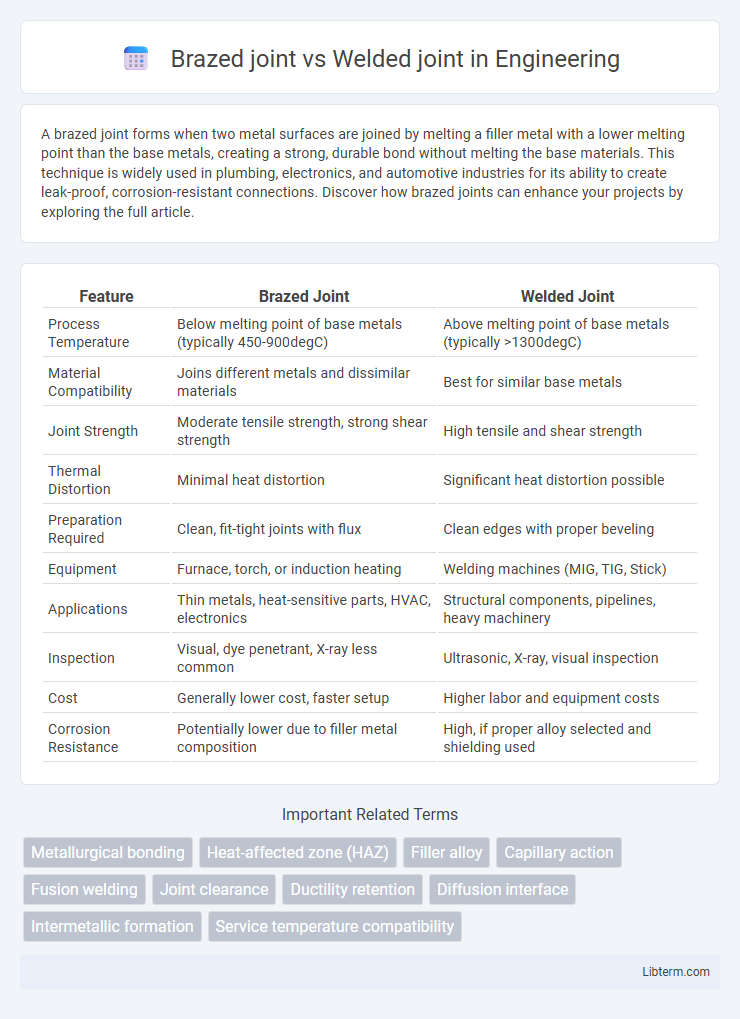

| Feature | Brazed Joint | Welded Joint |

|---|---|---|

| Process Temperature | Below melting point of base metals (typically 450-900degC) | Above melting point of base metals (typically >1300degC) |

| Material Compatibility | Joins different metals and dissimilar materials | Best for similar base metals |

| Joint Strength | Moderate tensile strength, strong shear strength | High tensile and shear strength |

| Thermal Distortion | Minimal heat distortion | Significant heat distortion possible |

| Preparation Required | Clean, fit-tight joints with flux | Clean edges with proper beveling |

| Equipment | Furnace, torch, or induction heating | Welding machines (MIG, TIG, Stick) |

| Applications | Thin metals, heat-sensitive parts, HVAC, electronics | Structural components, pipelines, heavy machinery |

| Inspection | Visual, dye penetrant, X-ray less common | Ultrasonic, X-ray, visual inspection |

| Cost | Generally lower cost, faster setup | Higher labor and equipment costs |

| Corrosion Resistance | Potentially lower due to filler metal composition | High, if proper alloy selected and shielding used |

Introduction to Brazed and Welded Joints

Brazed joints utilize a filler metal with a melting point above 450degC but below the base metals' melting points, bonding components without melting the main materials, ideal for joining dissimilar metals or thin sections. Welded joints involve melting the base metals and adding filler material to create a strong, continuous bond, commonly used in structural applications requiring high strength and durability. Brazing offers precision and minimal thermal distortion, while welding provides superior mechanical strength and integrity for heavy-duty uses.

Definition and Process Overview

Brazed joints involve joining metals by melting a filler metal with a lower melting point than the base metals, which are not melted during the process, creating a strong bond through capillary action. Welding joins metals by melting both the base metals and often adding filler material, resulting in a fused joint with high structural integrity. Brazing typically requires lower temperatures and is used for delicate or dissimilar metals, while welding demands higher heat and is suited for heavy-duty applications.

Material Compatibility

Brazed joints offer superior material compatibility by allowing the joining of dissimilar metals such as copper to steel or aluminum without melting the base materials, preserving their mechanical properties. Welded joints require similar or compatible metals with comparable melting points to form a strong fusion bond, limiting the range of materials that can be joined effectively. Brazing is preferred for delicate components or when joining materials with different thermal expansion rates to avoid thermal distortion.

Strength and Durability Comparison

Brazed joints typically offer high strength with a uniform bond and excellent resistance to corrosion due to the filler metal used, making them suitable for thin materials and delicate components. Welded joints, on the other hand, provide superior mechanical strength by fusing base metals directly, resulting in a more robust and durable connection ideal for heavy-duty applications and structural components. Durability in welded joints generally surpasses brazed joints under high stress and temperature conditions, though brazing ensures better thermal expansion compatibility and reduced metal distortion.

Temperature Resistance

Brazed joints typically withstand temperatures up to 450-500degC (842-932degF), making them suitable for moderate temperature applications, while welded joints can resist much higher temperatures, often exceeding 1,200degC (2,192degF), due to their fusion of base metals. The metallurgical bond in welded joints provides superior thermal stability and mechanical strength under extreme heat compared to the filler metal interface in brazed joints. This temperature resistance difference significantly impacts the selection of joining methods in industries such as aerospace, automotive, and power generation, where thermal performance is critical.

Joint Appearance and Precision

Brazed joints exhibit smooth, clean seams with minimal distortion due to lower processing temperatures, resulting in precise and aesthetically pleasing connections. Welded joints often show visible bead patterns and heat-affected zones, which can cause slight warping and less uniform surface finish. The superior control in brazing allows for tighter tolerances and more consistent joint appearance compared to welding.

Applications in Industry

Brazed joints are widely used in the electronics and HVAC industries for joining dissimilar metals with minimal thermal distortion and excellent corrosion resistance. Welded joints dominate heavy industries such as construction, automotive, and shipbuilding due to their high strength and ability to withstand significant mechanical stresses. Both methods are chosen based on application-specific requirements like joint strength, thermal sensitivity, and production efficiency.

Cost Considerations

Brazed joints generally incur lower labor costs due to faster processing times and less specialized equipment compared to welded joints, which require skilled welders and often more extensive preparation. Material costs for brazing can be higher because of the filler metals, but overall expenses tend to be lower in volume production. Welding, while potentially more expensive due to consumables and energy requirements, offers greater strength and durability that may justify the higher initial investment in critical structural applications.

Inspection and Quality Control

Inspection of brazed joints relies on visual examination, leak testing, and X-ray radiography to detect voids and incomplete wetting, emphasizing cleanliness and precise temperature control for quality assurance. Welded joint inspection integrates ultrasonic testing, magnetic particle inspection, and dye penetrant testing to identify cracks, porosity, and inclusions, with strict adherence to welding procedure specifications (WPS) and welder qualifications ensuring structural integrity. Quality control for brazing prioritizes joint fit-up and flux removal, whereas welding demands stringent monitoring of heat input and interpass temperature to prevent defects and maintain joint strength.

Choosing the Right Joint Method

Choosing between brazed and welded joints depends on factors like material types, joint strength requirements, and thermal sensitivity. Brazed joints offer strong, leak-proof seals ideal for dissimilar metals and thin materials with lower heat input. Welded joints provide superior mechanical strength and durability, suited for load-bearing applications and thicker metals requiring fusion.

Brazed joint Infographic

libterm.com

libterm.com