Fault Tree Analysis (FTA) is a systematic, top-down approach used to identify the root causes of system failures by visually mapping the relationships between various faults. This method helps in assessing risk, enhancing safety, and improving system reliability through structured problem-solving. Explore the rest of the article to understand how FTA can optimize your risk management processes.

Table of Comparison

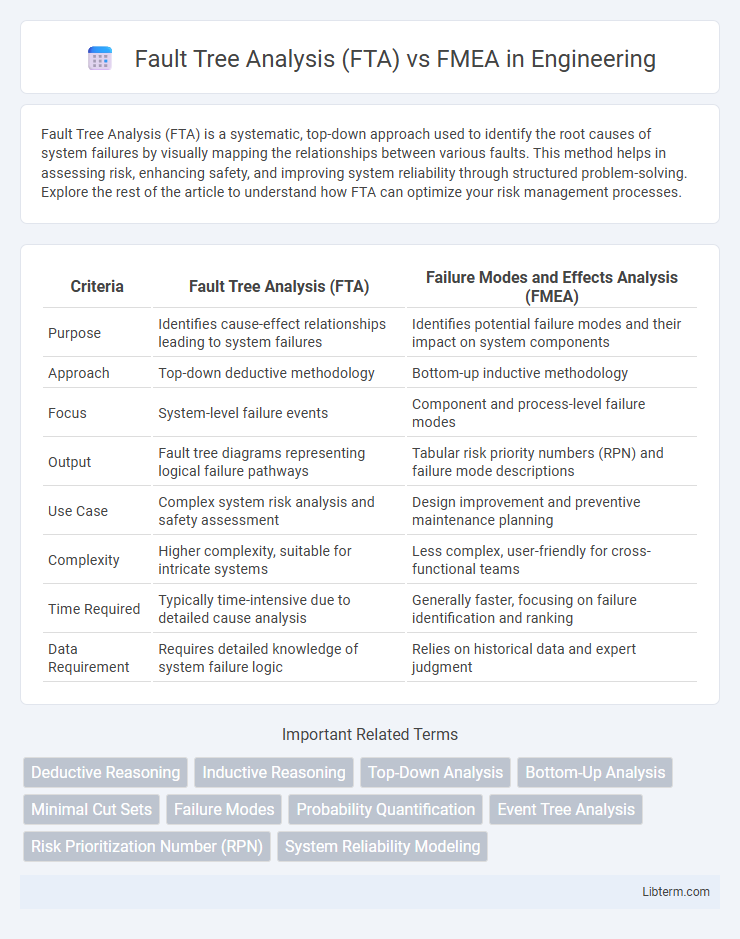

| Criteria | Fault Tree Analysis (FTA) | Failure Modes and Effects Analysis (FMEA) |

|---|---|---|

| Purpose | Identifies cause-effect relationships leading to system failures | Identifies potential failure modes and their impact on system components |

| Approach | Top-down deductive methodology | Bottom-up inductive methodology |

| Focus | System-level failure events | Component and process-level failure modes |

| Output | Fault tree diagrams representing logical failure pathways | Tabular risk priority numbers (RPN) and failure mode descriptions |

| Use Case | Complex system risk analysis and safety assessment | Design improvement and preventive maintenance planning |

| Complexity | Higher complexity, suitable for intricate systems | Less complex, user-friendly for cross-functional teams |

| Time Required | Typically time-intensive due to detailed cause analysis | Generally faster, focusing on failure identification and ranking |

| Data Requirement | Requires detailed knowledge of system failure logic | Relies on historical data and expert judgment |

Introduction to FTA and FMEA

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis technique used to identify the root causes of system failures by mapping out fault events in a tree structure. Failure Modes and Effects Analysis (FMEA) is a bottom-up, inductive approach that examines potential failure modes within components or processes and assesses their effects on system performance. Both methodologies are essential for risk assessment and reliability engineering, with FTA focusing on failure causality and FMEA emphasizing failure prevention and mitigation.

Defining Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method used to identify the root causes of system failures by mapping logical relationships between faults and their consequences. It visually represents fault events using Boolean logic to analyze complex system reliability and safety. In contrast, Failure Modes and Effects Analysis (FMEA) takes a bottom-up approach, focusing on identifying potential failure modes, their causes, and effects at the component level.

Defining Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) is a systematic approach used to identify potential failure modes within a system, assess their causes and effects, and prioritize risks based on severity, occurrence, and detectability. Unlike Fault Tree Analysis (FTA), which uses a top-down approach to model system failures through Boolean logic, FMEA takes a bottom-up perspective by examining components or processes individually to predict failure points. FMEA enhances reliability and safety by enabling proactive risk mitigation through detailed failure mode identification and impact evaluation.

Key Objectives of FTA and FMEA

Fault Tree Analysis (FTA) primarily aims to identify the root causes of system failures by mapping out logical relationships between various sub-system faults and their contributions to a top-level failure event, enabling prioritized risk mitigation strategies. Failure Modes and Effects Analysis (FMEA) focuses on systematically analyzing potential failure modes within a design, process, or system, assessing their effects on overall performance to improve reliability and safety through preventive actions. Both methodologies enhance risk management, but FTA provides a deductive, top-down approach, while FMEA employs an inductive, bottom-up evaluation of potential failures.

Methodology of Fault Tree Analysis

Fault Tree Analysis (FTA) employs a top-down, deductive methodology starting from a defined system failure and working backward to identify all possible root causes using logic gates like AND and OR. This structured approach enables visualization of complex failure pathways, quantification of failure probabilities, and prioritization of system vulnerabilities. FTA contrasts with FMEA's bottom-up, inductive technique by focusing on failure events' interrelations and their contribution to system-level faults.

Methodology of FMEA

Failure Modes and Effects Analysis (FMEA) employs a systematic approach to identify potential failure modes within a system, assess their causes and effects, and prioritize them based on risk through Risk Priority Numbers (RPN). This methodology involves detailed steps such as defining the scope, listing components, determining failure modes, analyzing their effects and causes, and implementing mitigation actions. Compared to Fault Tree Analysis (FTA), which uses a top-down logic diagram to trace the pathways to a system failure, FMEA is bottom-up and emphasizes early detection and prevention of specific failure modes in design and process stages.

Comparative Strengths of FTA vs FMEA

Fault Tree Analysis (FTA) excels in identifying the root causes of system-level failures by visually mapping event relationships and logic gates, enabling quantitative probability assessments. Failure Mode and Effects Analysis (FMEA) provides detailed insight into potential component-level failure modes and their effects, prioritizing risks through severity, occurrence, and detection rankings. While FTA is superior for complex system fault diagnostics and top-down analysis, FMEA offers strengths in early design phase risk identification and failure prevention at a granular level.

Limitations and Challenges of FTA and FMEA

Fault Tree Analysis (FTA) struggles with complexity in modeling large systems due to combinatorial explosion and reliance on accurate fault data, making it less effective in dynamic or probabilistically uncertain environments. Failure Mode and Effects Analysis (FMEA) faces limitations in capturing interdependencies between failure modes and often lacks quantitative risk prioritization, leading to potential oversight of critical failure interactions. Both techniques require expert judgment, which can introduce subjective bias and variability in results, affecting the comprehensiveness and accuracy of failure identification and risk assessment.

Best Use Cases for FTA and FMEA

Fault Tree Analysis (FTA) is best used for identifying the root causes of system-level failures and analyzing complex failure scenarios involving multiple components or events. Failure Modes and Effects Analysis (FMEA) excels in detailed examination of individual components or processes to prioritize risks and implement preventive actions. FTA is ideal for system reliability and safety-critical industries, while FMEA is more effective for design-phase risk assessment and process improvement.

Conclusion: Choosing Between FTA and FMEA

Fault Tree Analysis (FTA) excels in identifying root causes of system failures through a graphical, top-down approach, making it ideal for complex systems with interdependent failures. Failure Modes and Effects Analysis (FMEA) prioritizes potential failure modes based on severity, occurrence, and detectability, offering a bottom-up, component-level assessment best suited for design and process improvements. Selecting between FTA and FMEA depends on project goals: use FTA for in-depth fault isolation in critical systems and FMEA for proactive risk mitigation during early development stages.

Fault Tree Analysis (FTA) Infographic

libterm.com

libterm.com