Project Portfolio Management (PPM) optimizes resource allocation and prioritizes projects to align with organizational goals, enhancing efficiency and decision-making. Statistical Process Control (SPC) uses data-driven techniques to monitor and control production processes, ensuring consistent quality and reducing variability. Discover how integrating PPM and SPC can transform your project outcomes by reading the full article.

Table of Comparison

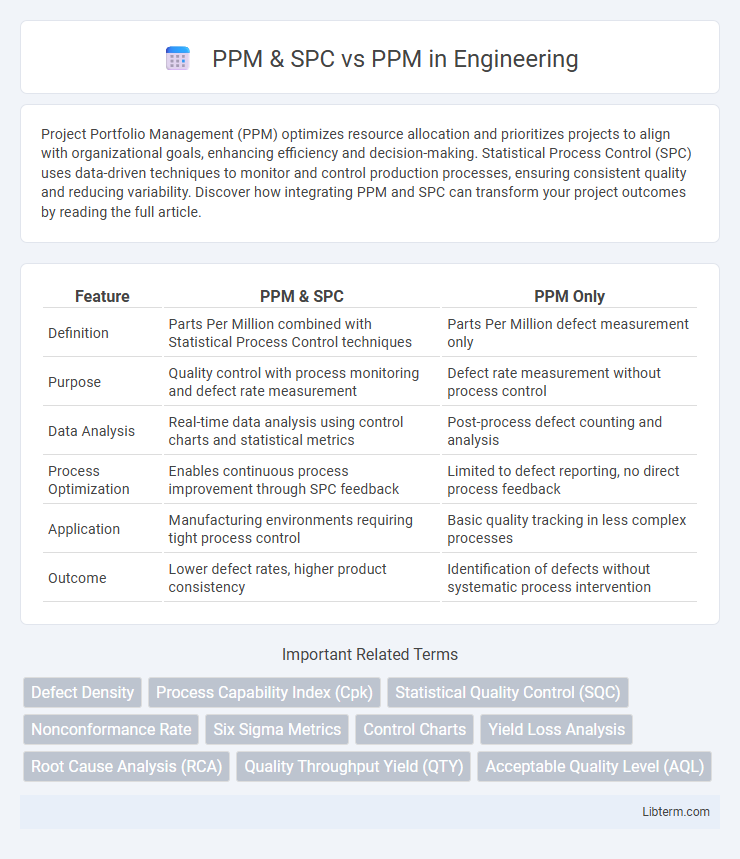

| Feature | PPM & SPC | PPM Only |

|---|---|---|

| Definition | Parts Per Million combined with Statistical Process Control techniques | Parts Per Million defect measurement only |

| Purpose | Quality control with process monitoring and defect rate measurement | Defect rate measurement without process control |

| Data Analysis | Real-time data analysis using control charts and statistical metrics | Post-process defect counting and analysis |

| Process Optimization | Enables continuous process improvement through SPC feedback | Limited to defect reporting, no direct process feedback |

| Application | Manufacturing environments requiring tight process control | Basic quality tracking in less complex processes |

| Outcome | Lower defect rates, higher product consistency | Identification of defects without systematic process intervention |

Understanding PPM: Definition and Importance

PPM (Parts Per Million) is a critical quality metric used to quantify the number of defective units in a million produced, enabling manufacturers to assess product reliability and identify improvement areas. SPC (Statistical Process Control) integrates PPM data with control charts and statistical methods to monitor and control production processes in real-time, reducing variability and defects. Understanding PPM's role in quality management highlights its importance in setting benchmarks and driving continuous process improvements within manufacturing operations.

What is SPC? Fundamentals and Applications

Statistical Process Control (SPC) is a quality management method that utilizes statistical tools to monitor and control manufacturing processes, aiming to reduce variability and defects. SPC relies on control charts and real-time data analysis to detect process deviations and maintain consistent product quality. Unlike Parts Per Million (PPM), which quantifies defect rates, SPC proactively prevents defects by identifying and addressing process variations during production.

The Role of PPM in Quality Management

PPM (Parts Per Million) is a critical metric in quality management that quantifies the number of defective parts per million produced, enabling precise measurement of production quality. SPC (Statistical Process Control) complements PPM by using statistical methods to monitor and control manufacturing processes, thus reducing variability and defects. PPM focuses on the outcome quality metric, while SPC emphasizes process control, making PPM essential for evaluating product quality performance and driving continuous improvement initiatives.

SPC Techniques for Quality Improvement

SPC (Statistical Process Control) techniques utilize control charts and process capability analysis to monitor, control, and improve manufacturing processes by identifying variations and preventing defects in real time. Unlike relying solely on PPM (parts per million) defect metrics, SPC provides actionable insights through continuous data analysis, enabling proactive adjustments before defects escalate. Implementing SPC methods drives significant quality improvement by reducing variability, enhancing process stability, and minimizing overall PPM rates in production environments.

PPM & SPC: A Comparative Overview

PPM (Parts Per Million) and SPC (Statistical Process Control) both serve quality management but differ fundamentally; PPM quantifies defect levels by measuring the number of defective units per million produced, serving as a key performance metric. SPC uses control charts and statistical methods to monitor and control process variability, enabling real-time detection of deviations and ensuring consistent process performance. Together, PPM provides the defect rate outcome while SPC offers a proactive approach to maintaining quality, making their combined use essential for effective process optimization.

Key Differences: PPM & SPC vs PPM Alone

PPM & SPC combines Project Portfolio Management with Statistical Process Control, enabling organizations to monitor project quality through data-driven process control, whereas PPM alone focuses solely on aligning projects with strategic goals without continuous process measurement. The integration of SPC in PPM facilitates real-time quality monitoring, reducing defects and improving consistency across project deliverables, which PPM alone lacks. This synergy enhances decision-making by providing both project prioritization and process performance insights, optimizing resource allocation and product quality simultaneously.

Advantages of Integrating SPC with PPM

Integrating Statistical Process Control (SPC) with Parts Per Million (PPM) measurement enhances quality management by enabling real-time monitoring and early detection of defects, reducing the likelihood of defects exceeding PPM targets. SPC's data-driven control charts and process capability analysis improve process stability, directly lowering PPM rates and ensuring compliance with industry standards. This integration facilitates continuous improvement and cost savings by minimizing product rework and scrap through precise process adjustments.

Limitations of Relying Solely on PPM

Relying solely on Parts Per Million (PPM) as a quality metric limits the ability to detect underlying process variations and trends critical for continuous improvement. Statistical Process Control (SPC) complements PPM by providing real-time monitoring through control charts, enabling early identification of deviations before defects occur. Ignoring SPC and focusing only on PPM can result in reactive quality management rather than proactive process optimization.

Industry Use Cases: PPM & SPC Implementation

PPM (Parts Per Million) and SPC (Statistical Process Control) are critical quality management tools widely implemented in manufacturing to monitor and reduce defects. Industry use cases demonstrate that combining PPM metrics with SPC techniques enables real-time process optimization, driving improved product consistency and reduced defect rates in automotive, aerospace, and electronics sectors. This integrated approach supports data-driven decision-making, enhancing production efficiency and compliance with strict quality standards like ISO 9001 and IATF 16949.

Best Practices for Combining PPM and SPC

Combining Project Portfolio Management (PPM) and Statistical Process Control (SPC) optimizes project outcomes through data-driven decision-making and quality control integration. Effective implementation involves aligning SPC metrics with portfolio objectives, enabling real-time performance tracking and risk mitigation across projects. Best practices include establishing cross-functional teams to synchronize quality standards, leveraging SPC dashboards within PPM tools, and continuous process improvement to ensure project alignment with strategic goals.

PPM & SPC Infographic

libterm.com

libterm.com