Additive action occurs when two or more substances or forces combine to produce a total effect equal to the sum of their individual effects, often observed in chemistry and pharmacology during drug interactions. Understanding additive action helps you predict outcomes when multiple agents work together, ensuring safe and effective applications. Explore the rest of the article to learn more about how additive action influences various fields.

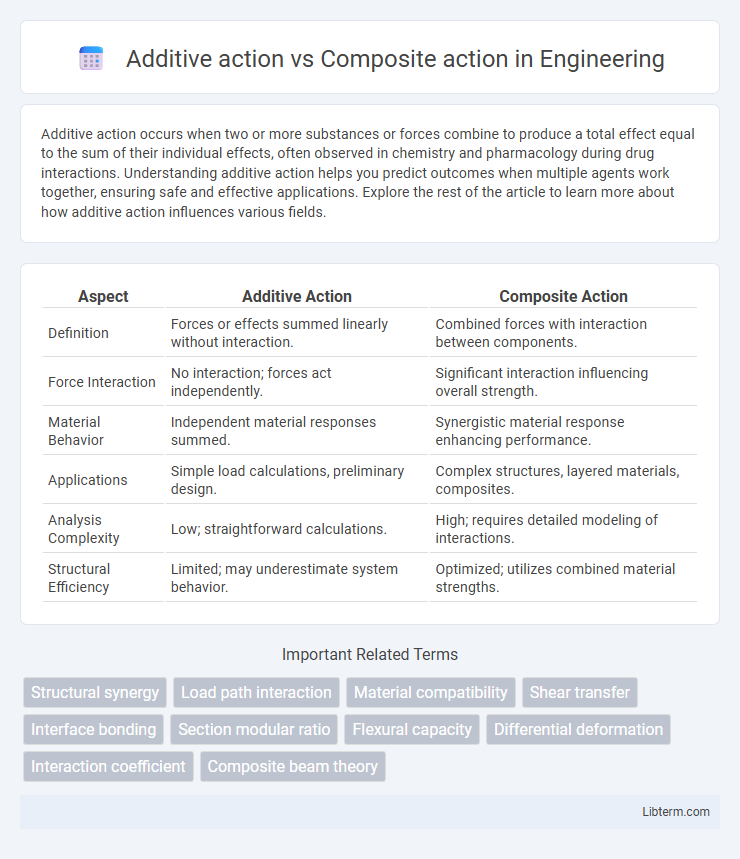

Table of Comparison

| Aspect | Additive Action | Composite Action |

|---|---|---|

| Definition | Forces or effects summed linearly without interaction. | Combined forces with interaction between components. |

| Force Interaction | No interaction; forces act independently. | Significant interaction influencing overall strength. |

| Material Behavior | Independent material responses summed. | Synergistic material response enhancing performance. |

| Applications | Simple load calculations, preliminary design. | Complex structures, layered materials, composites. |

| Analysis Complexity | Low; straightforward calculations. | High; requires detailed modeling of interactions. |

| Structural Efficiency | Limited; may underestimate system behavior. | Optimized; utilizes combined material strengths. |

Understanding Additive Action: Definition and Principles

Additive action refers to the process where the total effect is the sum of individual actions or forces applied independently and simultaneously, following the principle of superposition. This concept is essential in fields like structural engineering and physics, where the combined influence of multiple loads or forces is analyzed by adding their separate contributions. Understanding additive action allows for accurate prediction of system responses by considering each component's effect without interaction complexities.

What is Composite Action? Key Concepts Explained

Composite action refers to the combined effects of different structural elements working together to resist loads, enhancing overall strength and stability. Key concepts include the interaction between materials, such as steel and concrete in reinforced concrete beams, where both materials share stress and strain, optimizing load distribution. This synergy reduces deflection and improves performance compared to additive action, where individual elements act independently without load-sharing.

Fundamental Differences: Additive Action vs Composite Action

Additive action refers to the combined effect of multiple forces or stresses acting independently, where the total response is the simple sum of individual effects. Composite action involves the interaction between different materials or structural elements that act together to resist loads, resulting in enhanced overall strength and stiffness due to load sharing and compatibility. The fundamental difference lies in additive action treating components separately with straightforward summation, while composite action integrates components to function as a unified system with synergistic performance.

Real-World Examples of Additive Action

Additive action occurs when multiple forces or effects combine linearly, resulting in a total impact equal to the sum of individual influences. Real-world examples include the combined forces of multiple engines propelling an aircraft or the cumulative rainfall from several storms contributing to river water levels. In contrast, composite action involves complex interactions where combined effects are not simply additive but interdependent, such as in reinforced concrete where steel and concrete work together structurally.

Practical Applications of Composite Action

Composite action combines the effects of steel and concrete in structural elements, enhancing load-carrying capacity and efficiency. In practical applications, composite beams and slabs are widely used in bridge construction and high-rise buildings to optimize material usage and reduce deflection. This synergy improves overall structural performance, resulting in cost-effective and durable designs.

Mathematical Models Behind Additive and Composite Actions

Additive action models in structural engineering assume that the total response is the direct sum of individual component effects, mathematically represented as \( R = R_1 + R_2 + \cdots + R_n \), where \( R_i \) denotes the response from each isolated load or effect. Composite action models incorporate interaction terms between components, expressed through coupled differential equations or matrix formulations such as \( \mathbf{R} = \mathbf{A} \mathbf{x} + \mathbf{B} \mathbf{x} \cdot \mathbf{C} \mathbf{x} \), capturing nonlinear dependencies and synergistic effects. The mathematical distinction lies in the linear superposition principle for additive actions versus the multiplicative or nonlinear operators in composite models, essential for accurately predicting complex structural behavior under combined loadings.

Advantages and Limitations of Additive Action

Additive action in structural engineering allows for the combination of multiple loads by directly summing their effects, which simplifies analysis and improves accuracy in predicting structural response under various conditions. This method enhances design efficiency by enabling straightforward superposition of load effects, reducing conservatism compared to composite action, which merges different materials or elements to act as a single unit. However, additive action may face limitations in complex structures with nonlinear behavior or interaction effects that composite action models better, as it might not capture the synergistic performance between materials or components accurately.

Benefits and Drawbacks of Composite Action

Composite action combines steel and concrete to maximize structural efficiency, resulting in enhanced load-bearing capacity and reduced material usage, which leads to cost savings and lighter structures. Its drawbacks include complex design requirements, potential construction challenges due to the need for proper bonding between materials, and increased initial setup time compared to additive action. Despite these challenges, composite action offers superior durability and performance in modern structural engineering applications.

Comparing Additive and Composite Action in Engineering

Additive action in engineering involves the direct summation of individual forces or effects acting simultaneously on a structure, resulting in a combined impact that can be easily quantified. Composite action refers to the interaction between different materials or structural components that work together to resist loads more efficiently, often leading to enhanced strength and stiffness compared to the sum of individual parts. Comparing additive and composite actions highlights that additive action assumes linear superposition, while composite action relies on the synergistic behavior and load sharing between components within engineered systems.

Choosing the Right Approach: Guidelines and Considerations

Choosing between additive action and composite action depends on the structural requirements and load distribution characteristics of the project. Additive action is ideal for scenarios where individual components bear loads independently without interaction, while composite action leverages the combined strength of materials or elements working together to resist loads more efficiently. Key considerations include material compatibility, connection design, expected load types, and construction complexity to ensure optimal performance and cost-effectiveness.

Additive action Infographic

libterm.com

libterm.com