Transition fit ensures precise alignment between two mating parts by accommodating slight allowances for easy assembly and controlled movement. This type of fit balances the need for secure positioning with the flexibility required for operational adjustments under varying conditions. Explore the rest of the article to understand how transition fits can optimize your mechanical designs.

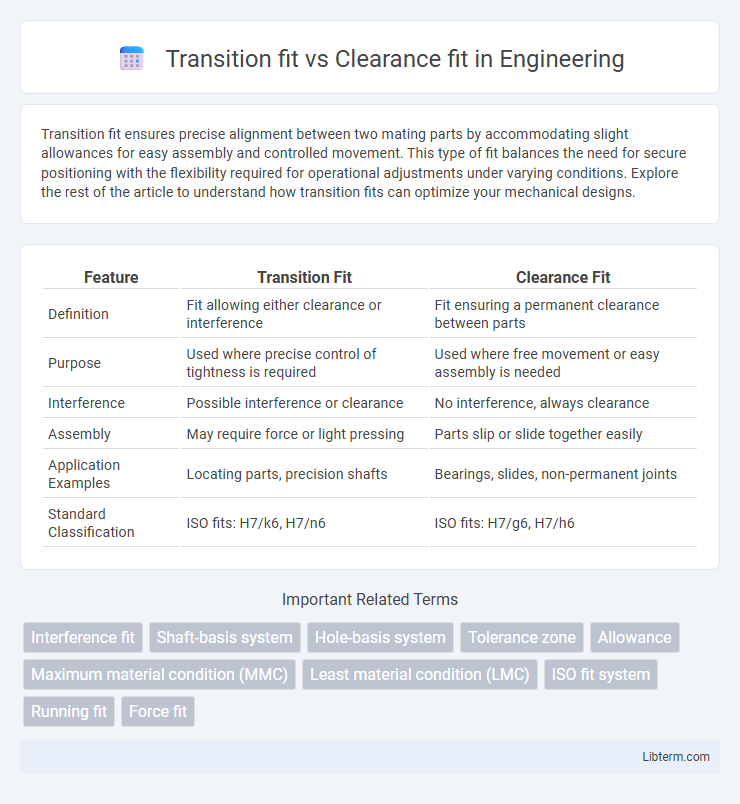

Table of Comparison

| Feature | Transition Fit | Clearance Fit |

|---|---|---|

| Definition | Fit allowing either clearance or interference | Fit ensuring a permanent clearance between parts |

| Purpose | Used where precise control of tightness is required | Used where free movement or easy assembly is needed |

| Interference | Possible interference or clearance | No interference, always clearance |

| Assembly | May require force or light pressing | Parts slip or slide together easily |

| Application Examples | Locating parts, precision shafts | Bearings, slides, non-permanent joints |

| Standard Classification | ISO fits: H7/k6, H7/n6 | ISO fits: H7/g6, H7/h6 |

Understanding Fit Types: Transition vs Clearance

Transition fit offers a precise combination of interference and clearance, enabling components to either slide together or create a tight press fit, ideal for applications requiring controlled alignment and moderate force. Clearance fit provides intentional space between parts, ensuring easy assembly and free movement, commonly used in mechanisms where components must rotate or slide smoothly without binding. Understanding these fit types aids engineers in selecting the appropriate tolerance class to balance ease of assembly with functional stability in mechanical design.

Definition of Transition Fit

Transition fit refers to a type of fit between two mating parts where the tolerance zones of the shaft and hole overlap, allowing for either a small clearance or slight interference. This fit provides a balance between clearance and interference fits, enabling parts to be assembled with precision without excessive tightness or looseness. Transition fit is commonly used in applications requiring accurate alignment and moderate force for assembly or disassembly.

Definition of Clearance Fit

Clearance fit occurs when the shaft diameter is always smaller than the hole diameter, ensuring free movement between the assembled parts without any interference. This type of fit guarantees a measurable amount of space or clearance, allowing for easy assembly and disassembly while minimizing friction. Common applications include bearings and sliding mechanisms where unrestricted motion is essential.

Key Differences Between Transition and Clearance Fits

Transition fit provides a range where parts may either have a small clearance or interference, enabling easy assembly with some tightness, while clearance fit always ensures a gap between mating parts for free movement. Transition fit is commonly used in applications requiring precise alignment without excessive force, whereas clearance fit prioritizes easy installation and removal. The key difference lies in the tolerance ranges: transition fits straddle zero line tolerances, and clearance fits have allowances strictly above zero ensuring no interference.

Applications of Transition Fit

Transition fit is widely used in applications where moderate precision and adjustable assembly strength are required, such as in automotive components and machine tool parts. This fit allows for either a slight clearance or interference, making it ideal for parts that must be assembled or disassembled without damaging the components. Common uses include coupling shafts to gears or pulleys where controlled tightness and ease of maintenance are essential.

Applications of Clearance Fit

Clearance fit is widely applied in engineering where easy assembly and disassembly of parts are critical, such as in shaft and hub connections, couplings, and fasteners. This fit ensures sufficient space between mating components, allowing for lubrication, thermal expansion, and tolerance variations without causing interference or stress. Typical applications include sliding mechanisms, bearings, and parts requiring frequent maintenance or adjustments.

Advantages of Transition Fit

Transition fit provides the unique advantage of offering a balance between interference and clearance fits, ensuring components can either slide or be pressed together with precise control. This fit type enhances assembly accuracy and reduces the risk of component movement or misalignment under operational stresses. Its adaptability makes it ideal for applications requiring moderate force for assembly while maintaining reliable positioning and ease of disassembly.

Advantages of Clearance Fit

Clearance fit allows components to assemble easily without force, reducing manufacturing complexity and costs. It provides reliable operation under varying conditions by maintaining space for thermal expansion, preventing seizure or binding. This fit type enhances serviceability with simpler disassembly and reassembly processes, crucial for maintenance tasks.

Factors Influencing Fit Selection

Material properties such as thermal expansion and hardness significantly influence the choice between transition fit and clearance fit, ensuring proper functionality under operational conditions. Load requirements and the need for precise alignment impact the selection, with transition fits offering moderate interference for controlled positioning while clearance fits allow free movement. Manufacturing tolerances and assembly conditions also play critical roles, affecting achievable fits and long-term performance in mechanical components.

Choosing the Right Fit for Engineering Projects

Selecting the appropriate fit type--transition fit or clearance fit--is crucial for engineering projects to ensure optimal assembly performance and durability. Transition fit offers controlled interference or slight clearance, ideal for applications requiring precise positioning without permanent fastening, while clearance fit guarantees free movement between parts, reducing the risk of jamming in assemblies like bearings or gears. Engineers must evaluate load conditions, thermal expansion, and ease of maintenance when choosing between these fits to achieve balance between stability and functionality.

Transition fit Infographic

libterm.com

libterm.com