Uniaxial stress occurs when a force is applied along a single axis, causing deformation in one direction. Understanding this concept is essential for analyzing material strength and predicting failure in engineering applications. Explore the rest of the article to learn how uniaxial stress influences structural integrity and design.

Table of Comparison

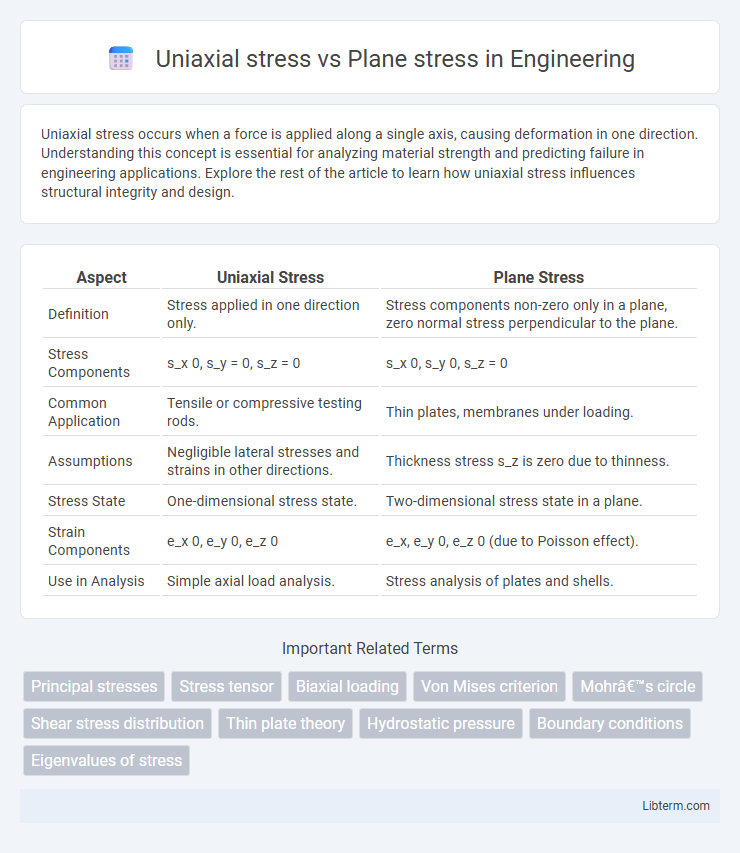

| Aspect | Uniaxial Stress | Plane Stress |

|---|---|---|

| Definition | Stress applied in one direction only. | Stress components non-zero only in a plane, zero normal stress perpendicular to the plane. |

| Stress Components | s_x 0, s_y = 0, s_z = 0 | s_x 0, s_y 0, s_z = 0 |

| Common Application | Tensile or compressive testing rods. | Thin plates, membranes under loading. |

| Assumptions | Negligible lateral stresses and strains in other directions. | Thickness stress s_z is zero due to thinness. |

| Stress State | One-dimensional stress state. | Two-dimensional stress state in a plane. |

| Strain Components | e_x 0, e_y 0, e_z 0 | e_x, e_y 0, e_z 0 (due to Poisson effect). |

| Use in Analysis | Simple axial load analysis. | Stress analysis of plates and shells. |

Introduction to Stress States in Materials

Uniaxial stress occurs when a material experiences force along a single axis, resulting in tension or compression without stress in the perpendicular directions. Plane stress describes a stress state where forces act in two dimensions, typically occurring in thin structures, with negligible thickness stress. Understanding these fundamental stress conditions is crucial for analyzing material deformation and failure in structural engineering and materials science.

Defining Uniaxial Stress

Uniaxial stress refers to the condition where stress is applied in only one direction or axis, typically characterized by a single non-zero principal stress component. This type of stress is commonly analyzed in tension or compression tests where the material experiences force along a single axis without significant stress in the perpendicular directions. Unlike plane stress, which involves two non-zero stress components confined to a plane, uniaxial stress simplifies analysis by focusing solely on one-dimensional loading conditions.

Understanding Plane Stress Condition

Plane stress condition occurs when the stress in the thickness direction of a thin structure is negligible compared to stresses in the plane, commonly in thin plates or sheets where s_z 0. This simplification allows engineers to analyze two-dimensional stress states using only s_x and s_y with shear stress t_xy, facilitating structural analysis in applications like aerospace and mechanical components. Understanding plane stress is crucial for accurate predictions of deformation and failure in materials subjected to surface loads without significant out-of-plane forces.

Mathematical Representation: Uniaxial vs. Plane Stress

Uniaxial stress is mathematically represented by a single non-zero normal stress component, typically s_x, with all other stress components equal to zero (s_y = s_z = t_xy = t_yz = t_xz = 0). Plane stress involves two non-zero in-plane normal stresses, s_x and s_y, and one shear stress t_xy, while out-of-plane stresses are zero (s_z = t_xz = t_yz = 0). The stress tensor for uniaxial stress simplifies to a diagonal matrix with one non-zero element, whereas for plane stress, the tensor includes a 2x2 submatrix of stresses in the plane with shear components considered.

Key Differences Between Uniaxial and Plane Stress

Uniaxial stress involves stress applied in a single direction, typically represented by a single non-zero normal stress component, while plane stress occurs when stresses act only in two dimensions with negligible out-of-plane stresses. In uniaxial stress, the material experiences normal stress along one axis and zero stress in the perpendicular directions, whereas plane stress assumes zero stress along the thickness, making it suitable for thin plates. The key differences include the dimensionality of stress states, stress components involved, and applicability to different structural elements such as rods for uniaxial stress and thin sheets for plane stress analysis.

Applications of Uniaxial Stress in Engineering

Uniaxial stress is predominantly applied in tensile testing to determine mechanical properties like Young's modulus and yield strength in materials engineering. Structural components such as beams and rods under axial loads experience uniaxial stress, making it crucial for analyzing load-bearing elements in civil, mechanical, and aerospace engineering. Its simplicity in stress state aids in failure prediction and design optimization in engineering applications.

Practical Examples of Plane Stress in Structures

Plane stress commonly occurs in thin structural elements such as metal sheets, aircraft fuselage panels, and thin-walled pressure vessels where the thickness is negligible compared to other dimensions. In these cases, stresses perpendicular to the plane, like the thickness direction, are minimal and often assumed to be zero for simplified analysis. Understanding plane stress conditions enables engineers to design safer, more efficient structures by accurately predicting stress distribution in thin components subjected to in-plane loads.

Effect on Material Behavior: Strength and Failure

Uniaxial stress simplifies the stress state by applying force along a single axis, often resulting in predictable tensile or compressive strength responses and well-defined failure modes like necking or fracture. Plane stress conditions, common in thin plates, involve stresses in two dimensions and typically lead to more complex failure mechanisms such as shear yielding or delamination due to stress interactions in the plane. Material behavior under plane stress generally exhibits lower apparent strength compared to uniaxial stress because multiaxial stresses accelerate damage and failure processes.

Experimental Methods for Identifying Stress States

Experimental methods for identifying uniaxial stress and plane stress states primarily involve strain gauge measurements and photoelasticity. Strain gauges provide localized strain data enabling the determination of principal stresses under uniaxial or plane stress conditions through calibrated elastic constants. Photoelastic techniques use polarized light to visualize stress contours, allowing the qualitative and quantitative assessment of stress distributions in two-dimensional plane stress scenarios.

Summary: Choosing Between Uniaxial and Plane Stress

Uniaxial stress involves stress applied along a single axis, often used for materials subjected to tension or compression in one direction, while plane stress assumes zero stress in the thickness direction, ideal for thin plates or shells under in-plane loading. Selecting between uniaxial and plane stress models depends on the geometry and loading conditions of the structure, with uniaxial stress suitable for rods and bars, and plane stress preferable for thin-walled components like aircraft wings or metal sheets. Accurate stress modeling enhances structural analysis, ensuring safety and performance in engineering applications.

Uniaxial stress Infographic

libterm.com

libterm.com