Induction motors are widely used in industrial applications due to their robustness, reliability, and efficiency in converting electrical energy into mechanical motion. These motors operate based on electromagnetic induction principles, eliminating the need for brushes and commutators, which reduces maintenance requirements. Explore the rest of the article to understand how an induction motor can optimize your machinery performance and energy consumption.

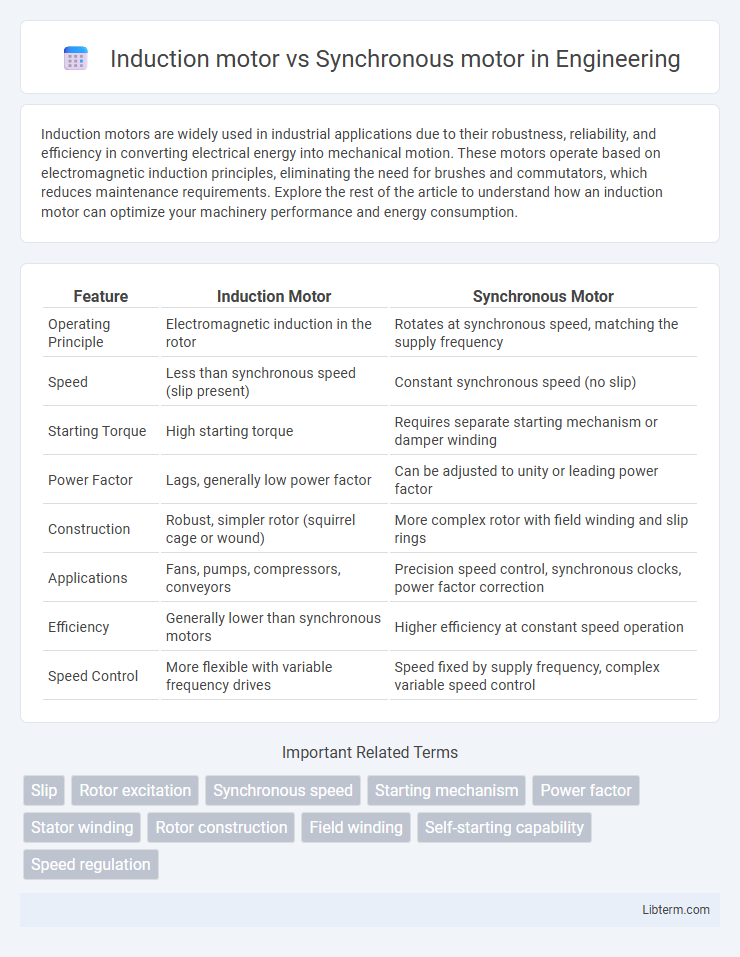

Table of Comparison

| Feature | Induction Motor | Synchronous Motor |

|---|---|---|

| Operating Principle | Electromagnetic induction in the rotor | Rotates at synchronous speed, matching the supply frequency |

| Speed | Less than synchronous speed (slip present) | Constant synchronous speed (no slip) |

| Starting Torque | High starting torque | Requires separate starting mechanism or damper winding |

| Power Factor | Lags, generally low power factor | Can be adjusted to unity or leading power factor |

| Construction | Robust, simpler rotor (squirrel cage or wound) | More complex rotor with field winding and slip rings |

| Applications | Fans, pumps, compressors, conveyors | Precision speed control, synchronous clocks, power factor correction |

| Efficiency | Generally lower than synchronous motors | Higher efficiency at constant speed operation |

| Speed Control | More flexible with variable frequency drives | Speed fixed by supply frequency, complex variable speed control |

Introduction to Induction and Synchronous Motors

Induction motors operate based on electromagnetic induction, where the rotor is induced by a rotating magnetic field generated in the stator, resulting in asynchronous speed relative to the supply frequency. Synchronous motors maintain a constant speed that matches the supply frequency, using a rotor excited by direct current, creating a magnetic field that locks in with the stator's rotating magnetic field. These fundamental differences in operation define their applications, with induction motors favored for robust, low-maintenance uses and synchronous motors valued for precise speed control and power factor correction.

Basic Working Principles

Induction motors operate on the principle of electromagnetic induction, where a rotating magnetic field in the stator induces current in the rotor, causing it to rotate asynchronously with the stator field. Synchronous motors function by locking the rotor speed with the rotating magnetic field of the stator, maintaining constant speed synchronous with the supply frequency through direct excitation of the rotor. The key difference lies in rotor operation: induction motors rely on induced currents, while synchronous motors require external excitation for rotor magnetization.

Construction and Components Comparison

Induction motors feature a squirrel-cage or wound rotor and a stator with a three-phase winding, relying on electromagnetic induction for rotor excitation, while synchronous motors consist of a rotor with permanent magnets or DC-excited field windings and a stator similar to that of the induction motor. The stator core of both motors is made of laminated silicon steel to reduce eddy current losses, but synchronous motors have additional components like slip rings or brushes for DC excitation in wound rotor types. Induction motors are simpler in construction with no external excitation required, whereas synchronous motors require a separate DC supply for the rotor, making their construction more complex and costly.

Operating Speed Characteristics

Induction motors operate at a speed slightly less than the synchronous speed, known as slip, which allows torque generation through electromagnetic induction. Synchronous motors run precisely at synchronous speed, matching the frequency of the supply current, resulting in zero slip and constant speed regardless of load variations. The slip in induction motors causes speed fluctuations under load, while synchronous motors maintain a fixed speed ideal for applications requiring precise speed control.

Starting Mechanisms and Requirements

Induction motors start by inducing current in the rotor windings through electromagnetic induction, requiring no external excitation, making their starting mechanism simpler and self-sufficient. Synchronous motors need an external DC power source to energize the rotor field winding and often require a separate starting method, such as an auxiliary motor or damper windings, to reach synchronous speed before locking in. The starting torque of induction motors is generally higher, whereas synchronous motors rely on additional devices or methods to achieve initial rotation.

Efficiency and Power Factor Differences

Induction motors generally exhibit lower efficiency and lagging power factor compared to synchronous motors, which achieve higher efficiency through constant speed operation and improved power factor by adjusting excitation. Induction motors often operate under varying loads with power factors around 0.7 to 0.85 lagging, whereas synchronous motors can maintain near unity or leading power factor, enhancing overall system performance. The capability of synchronous motors to correct power factor reduces reactive power demand, leading to energy savings and reduced utility penalties in industrial applications.

Applications and Use Cases

Induction motors are widely used in industrial applications such as conveyor systems, pumps, and fans due to their robust construction, low cost, and simple control requirements. Synchronous motors find applications in precise speed control scenarios, including robotics, clocks, and large power factor correction in electrical grids, where constant speed and synchronization with the power supply are critical. Both motor types serve essential roles in manufacturing, HVAC systems, and renewable energy sectors, selected based on performance needs like torque, speed regulation, and efficiency.

Advantages of Induction Motors

Induction motors offer robust construction and lower cost compared to synchronous motors, making them ideal for industrial applications. They require less maintenance due to their simple design and do not need an external excitation source, enhancing reliability and ease of use. Induction motors provide excellent starting torque and operate efficiently under varying load conditions, contributing to widespread adoption in manufacturing and heavy machinery.

Advantages of Synchronous Motors

Synchronous motors offer superior efficiency and precise speed control compared to induction motors, making them ideal for applications requiring constant speed under varying load conditions. They consume less reactive power due to their ability to operate at unity power factor or even leading power factor, which improves overall power system stability and reduces energy costs. The capability of synchronous motors to provide accurate phase synchronization makes them essential in industries such as manufacturing and power generation where consistent motor performance is critical.

Key Differences and Selection Criteria

Induction motors operate on electromagnetic induction principles, offering simple construction, robustness, and cost-effectiveness, making them ideal for general-purpose industrial applications. Synchronous motors provide constant speed operation synchronized with the supply frequency, suitable for precision-driven processes requiring high power factor correction and stable speed control. Selection criteria depend on application demands, with induction motors favored for variable loads and harsh environments, while synchronous motors are chosen for tasks needing exact speed regulation and power efficiency.

Induction motor Infographic

libterm.com

libterm.com