Synchronous motors operate by rotating at a speed directly proportional to the frequency of the supply current, making them ideal for applications requiring constant speed under varying loads. Their precise control and high efficiency benefit manufacturing processes and industrial machinery where timing and accuracy are critical. Discover how understanding synchronous motor technology can enhance your system's performance by reading the full article.

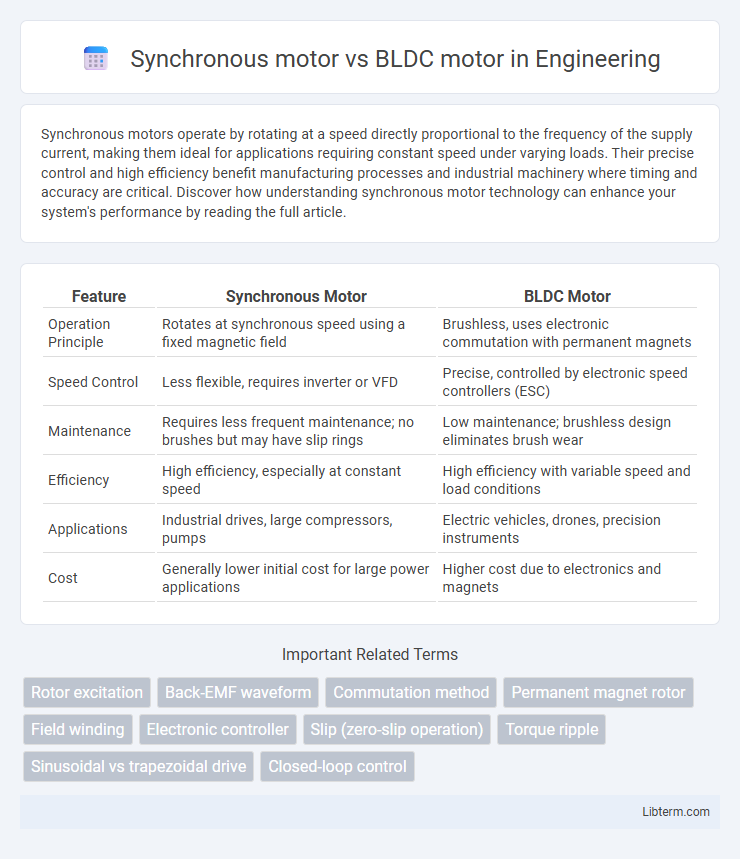

Table of Comparison

| Feature | Synchronous Motor | BLDC Motor |

|---|---|---|

| Operation Principle | Rotates at synchronous speed using a fixed magnetic field | Brushless, uses electronic commutation with permanent magnets |

| Speed Control | Less flexible, requires inverter or VFD | Precise, controlled by electronic speed controllers (ESC) |

| Maintenance | Requires less frequent maintenance; no brushes but may have slip rings | Low maintenance; brushless design eliminates brush wear |

| Efficiency | High efficiency, especially at constant speed | High efficiency with variable speed and load conditions |

| Applications | Industrial drives, large compressors, pumps | Electric vehicles, drones, precision instruments |

| Cost | Generally lower initial cost for large power applications | Higher cost due to electronics and magnets |

Introduction to Synchronous and BLDC Motors

Synchronous motors operate at a constant speed synchronized with the supply frequency, utilizing rotor magnets or windings energized by DC current to produce a steady magnetic field. Brushless DC (BLDC) motors feature electronically commutated stator windings and permanent magnets on the rotor, offering high efficiency, precise speed control, and reduced maintenance due to the absence of brushes. Both motor types are widely used in industrial applications, with synchronous motors preferred for constant speed tasks and BLDC motors favored for variable speed and high-performance scenarios.

Basic Working Principles

Synchronous motors operate by rotating the rotor at the same speed as the stator's rotating magnetic field, achieved through direct current excitation or permanent magnets on the rotor. BLDC motors utilize electronic commutation to switch current in the stator windings, creating a rotating magnetic field that interacts with permanent magnets on the rotor to produce motion. The key difference lies in synchronous motors requiring an external excitation source for rotor magnetization, whereas BLDC motors use permanent magnets and electronic control for efficient torque generation.

Key Construction Differences

Synchronous motors feature wound rotor coils and often require external excitation through slip rings, while BLDC motors use permanent magnets on the rotor, eliminating the need for brushes and slip rings. The stator in synchronous motors typically consists of a concentrated or distributed winding designed for AC supply, whereas BLDC motors have a trapezoidal back-EMF waveform generated by stator windings energized through electronic commutation. This fundamental construction difference results in synchronous motors relying on magnetic field synchronization and BLDC motors achieving commutation via an electronic controller that switches current in the stator windings.

Performance Characteristics

Synchronous motors provide precise speed control with high torque at low speeds due to their constant synchronous speed operation, making them ideal for industrial applications requiring steady performance. BLDC motors exhibit high power-to-weight ratios and superior efficiency with low maintenance, benefiting applications that demand rapid acceleration and variable speed control. While synchronous motors excel in consistent load environments, BLDC motors outperform in scenarios requiring dynamic response and compact design.

Efficiency Comparison

Synchronous motors typically exhibit high efficiency at constant speeds due to their precise magnetic field synchronization, often achieving efficiency rates above 90%. BLDC (Brushless DC) motors offer superior efficiency in variable speed applications, with efficiencies commonly ranging from 85% to 95% because of reduced friction and electrical losses. The efficiency comparison depends largely on the specific operating conditions, with BLDC motors outperforming in applications requiring rapid speed changes and synchronous motors excelling in steady-state performance.

Control and Drive Requirements

Synchronous motors require complex control algorithms like vector control to regulate rotor position and maintain synchronous speed, often needing external sensors for accurate feedback. BLDC motors utilize electronic commutation with Hall effect sensors or sensorless control techniques, simplifying drive circuitry and enabling precise speed and torque control. Both motor types benefit from advanced digital controllers, but BLDC motors are generally favored in applications demanding high efficiency and compact, low-maintenance drives.

Common Applications

Synchronous motors are commonly used in industrial applications requiring precise speed control and constant speed, such as robotics, conveyors, and CNC machines. BLDC (Brushless DC) motors find widespread use in electric vehicles, drones, and household appliances due to their high efficiency, reliability, and low maintenance. Both motor types excel in performance but are selected based on application-specific requirements like torque, speed, and control complexity.

Advantages and Disadvantages

Synchronous motors provide precise speed control and high efficiency, making them ideal for industrial applications requiring constant speed and high torque; however, they often require complex control systems and are less efficient at low speeds. BLDC motors offer high power density, low maintenance due to brushless design, and excellent speed-torque characteristics, but they typically involve higher initial costs and complex electronic controllers. Choosing between synchronous and BLDC motors depends on application-specific needs such as efficiency, control complexity, and operational environment.

Cost and Maintenance Factors

Synchronous motors generally have lower initial costs due to simpler construction and established manufacturing processes, while BLDC motors tend to be more expensive because of their permanent magnets and advanced electronics. Maintenance for synchronous motors is often higher, as brushes and slip rings require regular servicing, whereas BLDC motors feature brushless designs that reduce maintenance needs and improve durability. The long-term cost-effectiveness of BLDC motors is favored in applications where reduced downtime and maintenance expenses are critical.

Future Trends and Innovations

Synchronous motors are evolving with advancements in magnetic materials and control algorithms, enhancing efficiency and torque precision for industrial automation and renewable energy applications. BLDC motors benefit from innovations in sensorless control and integrated power electronics, boosting reliability and compactness in electric vehicles and robotics. Future trends emphasize the integration of AI-based predictive maintenance and energy-saving designs for both motor types, driving smarter, more sustainable motion control solutions.

Synchronous motor Infographic

libterm.com

libterm.com