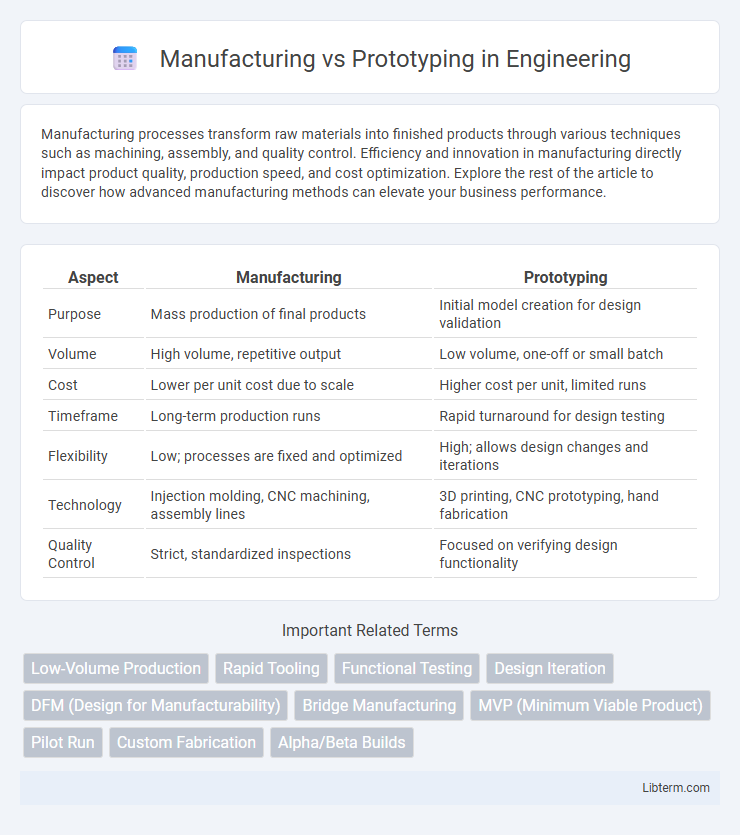

Manufacturing processes transform raw materials into finished products through various techniques such as machining, assembly, and quality control. Efficiency and innovation in manufacturing directly impact product quality, production speed, and cost optimization. Explore the rest of the article to discover how advanced manufacturing methods can elevate your business performance.

Table of Comparison

| Aspect | Manufacturing | Prototyping |

|---|---|---|

| Purpose | Mass production of final products | Initial model creation for design validation |

| Volume | High volume, repetitive output | Low volume, one-off or small batch |

| Cost | Lower per unit cost due to scale | Higher cost per unit, limited runs |

| Timeframe | Long-term production runs | Rapid turnaround for design testing |

| Flexibility | Low; processes are fixed and optimized | High; allows design changes and iterations |

| Technology | Injection molding, CNC machining, assembly lines | 3D printing, CNC prototyping, hand fabrication |

| Quality Control | Strict, standardized inspections | Focused on verifying design functionality |

Introduction: Defining Manufacturing and Prototyping

Manufacturing refers to the large-scale production of goods using standardized processes, machinery, and workforce to create finished products for market distribution. Prototyping involves the initial creation of a model or sample that tests design concepts, functionality, and feasibility before mass production. Both processes are critical in product development, with prototyping serving as a preliminary step to validate ideas and manufacturing focusing on efficient, high-volume output.

Key Differences Between Manufacturing and Prototyping

Manufacturing involves large-scale production of finished goods using standardized processes and automated machinery, while prototyping focuses on creating initial models or samples to test design concepts and functionality. Manufacturing typically requires higher investment, stringent quality control, and consistency across multiple units, whereas prototyping allows for flexibility, rapid iteration, and cost-effective experimentation. Key differences include production volume, purpose, cost, and time, with manufacturing aiming for mass production and prototyping emphasizing development and validation.

Objectives: Purpose of Prototyping vs Manufacturing

Prototyping aims to validate design concepts, identify potential flaws, and gather user feedback through iterative models before full-scale production. Manufacturing focuses on consistent, cost-effective mass production of finalized products to meet market demand. Prototyping serves experimentation and refinement, while manufacturing emphasizes efficiency and quality control.

Materials Used in Prototyping vs Manufacturing

Prototyping commonly employs materials such as PLA, ABS, resin, and foam due to their affordability, ease of use, and rapid production capabilities, enabling quick design iterations. In contrast, manufacturing typically utilizes durable and high-performance materials like aluminum, stainless steel, and engineering-grade plastics to ensure product longevity, functionality, and compliance with industry standards. The choice of materials directly impacts the cost, production time, and end-use applicability in both prototyping and manufacturing processes.

Production Volume and Scalability

Manufacturing is designed for high production volumes, enabling scalable output to meet large market demands efficiently, whereas prototyping focuses on low-volume, iterative development to refine designs before mass production. Scalability in manufacturing involves streamlined processes and automation to reduce costs per unit, while prototyping prioritizes flexibility and customization over speed and volume. Production volume in prototyping remains limited to a few units or samples, contrasting with manufacturing's ability to produce thousands or millions of consistent, quality-controlled products.

Cost Comparison: Prototyping vs Full-Scale Manufacturing

Prototyping incurs lower initial costs due to limited material use and simplified production processes, making it ideal for testing and design validation. Full-scale manufacturing demands significant upfront investment in tooling, molds, and setup, but benefits from economies of scale, reducing per-unit cost as production volume increases. Understanding the cost trade-offs between prototyping and manufacturing is essential for optimizing budget allocation in product development cycles.

Lead Time and Speed: Prototyping vs Manufacturing

Prototyping significantly reduces lead time by enabling rapid design iterations and quick validation of concepts, often completed within days or weeks. Manufacturing involves longer lead times due to complex tooling, batch production, and quality control processes, typically extending from weeks to months. Speed in prototyping accelerates innovation cycles, while manufacturing prioritizes volume efficiency and consistency in production output.

Quality Control and Testing in Both Processes

Quality control in manufacturing emphasizes consistency and scalability, employing rigorous inspections and automated testing to ensure each product meets exact standards. Prototyping focuses on iterative testing and validation, allowing designers to identify flaws and make adjustments before full-scale production. Both processes rely on quality control, but manufacturing prioritizes repeatability while prototyping centers on refinement and functional evaluation.

When to Choose Prototyping vs Manufacturing

Prototyping is ideal for testing design concepts, identifying flaws, and gathering user feedback before committing to large-scale production. Manufacturing should be chosen when the design is finalized, consistent quality is required, and cost efficiency at scale becomes a priority. Opt for prototyping during early development phases and manufacturing once product validation and optimization are complete.

Future Trends in Prototyping and Manufacturing

Future trends in prototyping emphasize advanced additive manufacturing techniques such as 3D printing with multi-material capabilities and accelerated production speeds, enabling rapid iteration and customization. Manufacturing is increasingly integrating Industry 4.0 technologies, including AI-driven automation, IoT sensors for real-time monitoring, and digital twins for predictive maintenance, enhancing efficiency and reducing downtime. Both prototyping and manufacturing are moving towards sustainable practices, utilizing eco-friendly materials and energy-efficient processes to lower environmental impact.

Manufacturing Infographic

libterm.com

libterm.com