Plate heat exchangers offer efficient heat transfer by using thin, corrugated plates that maximize surface area and enhance thermal performance. Their compact design ensures space-saving installation and easy maintenance, ideal for various industrial and HVAC applications. Discover how a plate heat exchanger can optimize your system by reading the full article.

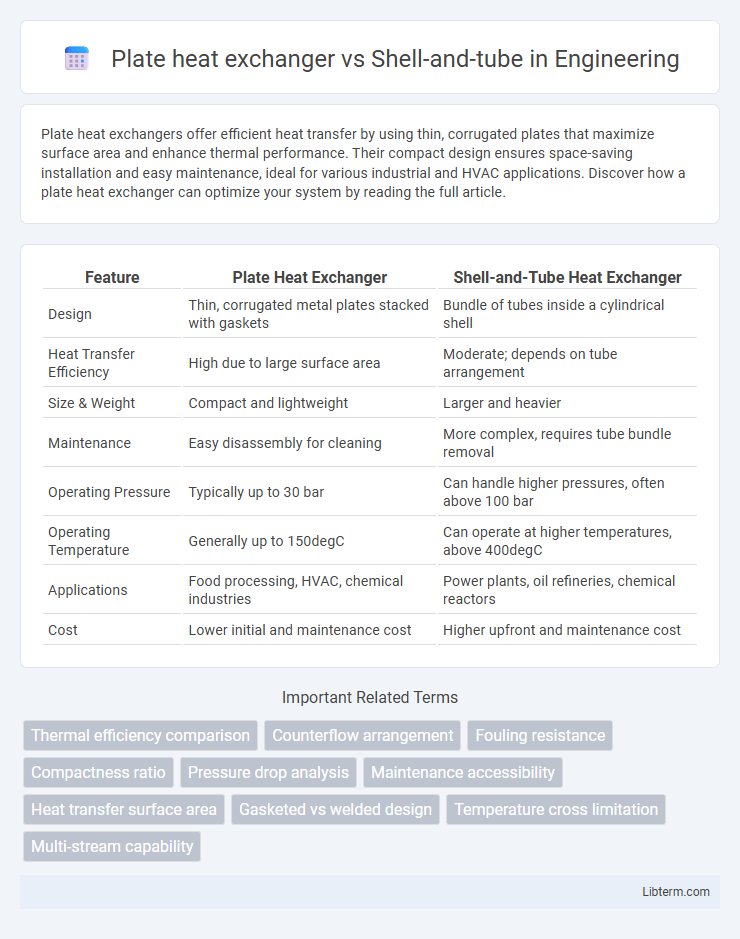

Table of Comparison

| Feature | Plate Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Design | Thin, corrugated metal plates stacked with gaskets | Bundle of tubes inside a cylindrical shell |

| Heat Transfer Efficiency | High due to large surface area | Moderate; depends on tube arrangement |

| Size & Weight | Compact and lightweight | Larger and heavier |

| Maintenance | Easy disassembly for cleaning | More complex, requires tube bundle removal |

| Operating Pressure | Typically up to 30 bar | Can handle higher pressures, often above 100 bar |

| Operating Temperature | Generally up to 150degC | Can operate at higher temperatures, above 400degC |

| Applications | Food processing, HVAC, chemical industries | Power plants, oil refineries, chemical reactors |

| Cost | Lower initial and maintenance cost | Higher upfront and maintenance cost |

Introduction to Plate and Shell-and-Tube Heat Exchangers

Plate heat exchangers feature multiple thin, corrugated metal plates stacked to maximize surface area for efficient heat transfer, making them ideal for compact installations and applications requiring high thermal performance. Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, facilitating the transfer of heat between two fluids with robust operation suited for high-pressure and high-temperature conditions. Both types are widely used in industries such as HVAC, chemical processing, and power generation, but plate heat exchangers excel in ease of maintenance and heat transfer efficiency while shell-and-tube systems offer greater durability and capacity for handling large fluid volumes.

How Plate Heat Exchangers Work

Plate heat exchangers operate by passing two fluids through alternating corrugated metal plates, maximizing surface area for efficient heat transfer while keeping the fluids separate. The design enables high turbulence and minimal fouling, resulting in superior thermal performance and compact size compared to shell-and-tube heat exchangers. This mechanism allows rapid heat exchange in applications like HVAC, refrigeration, and chemical processing.

How Shell-and-Tube Heat Exchangers Work

Shell-and-tube heat exchangers operate by directing one fluid through a series of tubes enclosed within a larger cylindrical shell, allowing heat transfer between the fluids without mixing. The fluid inside the tubes exchanges heat with the fluid flowing around the tubes in the shell, leveraging convection and conduction to maximize thermal efficiency. Their robust design accommodates high pressures and temperatures, making them suitable for industrial applications like oil refining and power generation.

Key Design Differences

Plate heat exchangers feature a compact design with multiple thin, corrugated plates that create high turbulence, enhancing heat transfer efficiency and allowing for easy maintenance and cleaning. Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, providing robust construction suitable for high-pressure and high-temperature applications but with lower heat transfer efficiency. The key design differences lie in the surface area per unit volume, flow arrangement flexibility, and ease of scalability, with plate heat exchangers offering greater thermal performance and shell-and-tube units excelling in durability and pressure resistance.

Heat Transfer Efficiency Comparison

Plate heat exchangers exhibit superior heat transfer efficiency due to their larger surface area per unit volume and turbulent flow conditions, which enhance thermal performance. Shell-and-tube heat exchangers typically have lower heat transfer coefficients because of their larger fluid passage diameters and less effective fluid dynamics. The compact design and close temperature approach in plate heat exchangers enable greater thermal efficiency compared to the traditional shell-and-tube models.

Space and Footprint Requirements

Plate heat exchangers offer a significantly smaller footprint compared to shell-and-tube designs due to their compact, modular plates that maximize heat transfer surface area within minimal space. Shell-and-tube exchangers require more installation space because of their bulky cylindrical shells and extensive tube bundles. Space constraints often make plate heat exchangers the preferred choice for facilities aiming to optimize layout efficiency and reduce operational footprint.

Maintenance and Cleaning Processes

Plate heat exchangers offer easier maintenance and cleaning due to their modular design, allowing individual plates to be removed, inspected, and cleaned without dismantling the entire unit. Shell-and-tube heat exchangers require periodic tube bundle removal for cleaning, often using mechanical or chemical methods, which can be more time-consuming and labor-intensive. The gasketed design of plate heat exchangers also facilitates faster disassembly and reassembly, reducing downtime compared to the welded construction typical of shell-and-tube units.

Typical Applications for Each Type

Plate heat exchangers excel in applications requiring efficient heat transfer with limited space, such as HVAC systems, food processing, and chemical industries where frequent cleaning or maintenance is needed. Shell-and-tube heat exchangers are preferred for high-pressure and high-temperature environments like power plants, oil refineries, and marine applications due to their robust design and ability to handle large volumes of fluids. Each type serves distinct industrial needs based on operational conditions and maintenance requirements.

Cost Considerations and Budget Impact

Plate heat exchangers generally offer lower initial costs and require less installation space compared to shell-and-tube models, making them budget-friendly for compact applications. Maintenance costs for plate heat exchangers tend to be lower due to easier cleaning and fewer components prone to failure, which can reduce operational expenses over time. Conversely, shell-and-tube exchangers may involve higher upfront investments and increased maintenance labor, but their robust design supports higher pressure and temperature applications, potentially justifying the expense in industrial settings.

Choosing the Right Heat Exchanger for Your Needs

Plate heat exchangers offer high heat transfer efficiency and compact design, making them ideal for applications with limited space and moderate pressure. Shell-and-tube heat exchangers are suitable for high-pressure, high-temperature scenarios and handle fouling fluids better, providing robust durability and easier maintenance. Choosing the right heat exchanger depends on factors like thermal performance, fluid properties, space constraints, and maintenance requirements to optimize system efficiency and longevity.

Plate heat exchanger Infographic

libterm.com

libterm.com