Commissioning ensures that your new systems and equipment operate according to design specifications, maximizing efficiency and safety. This critical process includes thorough testing, calibration, and validation to identify and resolve potential issues before full-scale operation. Discover how proper commissioning can save you time and costs by reading the rest of the article.

Table of Comparison

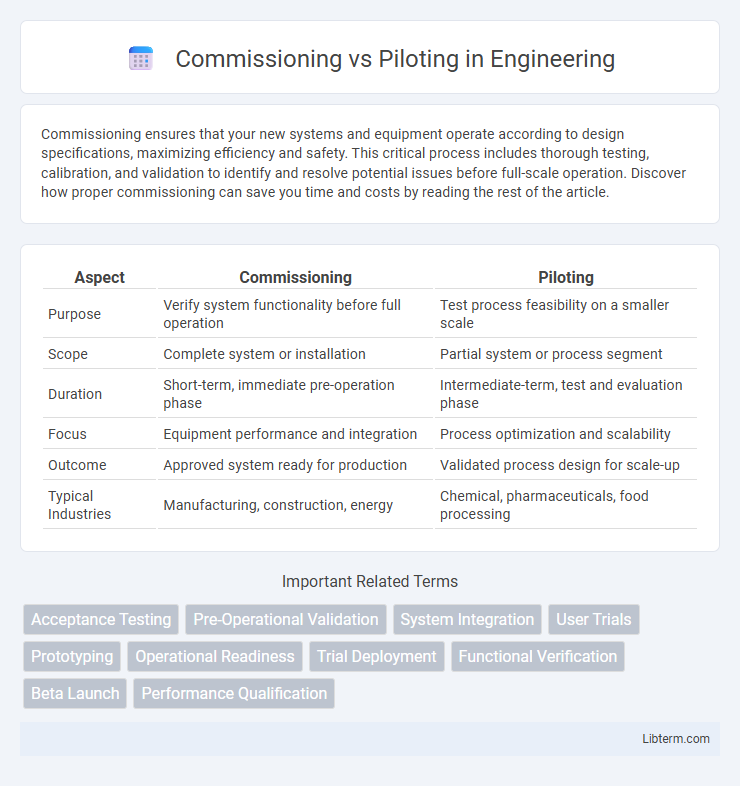

| Aspect | Commissioning | Piloting |

|---|---|---|

| Purpose | Verify system functionality before full operation | Test process feasibility on a smaller scale |

| Scope | Complete system or installation | Partial system or process segment |

| Duration | Short-term, immediate pre-operation phase | Intermediate-term, test and evaluation phase |

| Focus | Equipment performance and integration | Process optimization and scalability |

| Outcome | Approved system ready for production | Validated process design for scale-up |

| Typical Industries | Manufacturing, construction, energy | Chemical, pharmaceuticals, food processing |

Understanding Commissioning and Piloting

Commissioning involves verifying and documenting that all systems and components of a project are designed, installed, tested, and operating according to requirements, ensuring operational readiness. Piloting refers to testing a new process or system on a small scale to evaluate feasibility, identify issues, and gather data before full-scale implementation. Understanding commissioning ensures compliance and reliability, while piloting focuses on iterative learning and risk mitigation through controlled experimentation.

Key Differences Between Commissioning and Piloting

Commissioning involves verifying and validating that all systems, components, and equipment in a project are installed and functioning according to design specifications, ensuring readiness for full operational use. Piloting focuses on testing a new process, product, or system on a smaller scale to identify potential issues, gather data, and refine operations before full-scale implementation. The key difference lies in commissioning confirming system readiness post-installation, while piloting emphasizes experimental evaluation and adjustments during initial operational phases.

Objectives of Commissioning

Commissioning aims to verify and document that all building systems and components operate according to design specifications, ensuring safety, performance, and reliability. It includes systematic testing, adjusting, and balancing of HVAC, electrical, and control systems to meet operational requirements. This process reduces energy consumption, minimizes downtime, and supports long-term maintenance by identifying defects and functionality issues before full-scale operation.

Goals and Scope of Piloting

Piloting aims to validate and refine a system or process on a small scale before full deployment, focusing on identifying potential issues and gathering user feedback within a controlled environment. Its scope includes testing functionality, performance, and user interaction to ensure the solution meets business requirements and operational goals. Piloting provides actionable insights to optimize implementation strategies and mitigate risks prior to comprehensive commissioning.

Steps Involved in the Commissioning Process

Commissioning involves a series of methodical steps including design review, installation verification, functional performance testing, and system documentation to ensure operational reliability and compliance with specifications. The process begins with pre-commissioning activities such as equipment inspection and calibration, followed by integrated system testing to validate performance under real conditions. Final steps include staff training, handover documentation, and continuous monitoring to achieve optimal system functionality before full-scale operation.

Piloting Workflow Explained

Piloting workflow involves testing a new system or process in a controlled environment to validate its performance, identify potential issues, and gather user feedback before full-scale implementation. This phase includes steps such as defining objectives, selecting pilot participants, configuring the system, executing pilot runs, monitoring results, and analyzing data for improvements. Effective piloting minimizes risks and ensures smoother transitions by addressing challenges early in the deployment cycle.

Benefits of Commissioning

Commissioning ensures that systems and equipment are installed, tested, and calibrated to meet operational requirements, leading to optimized performance and reduced downtime. It provides validation of design intent and enhances safety by identifying issues before full-scale operation. This thorough process improves reliability, ensuring smoother transitions to production and minimizing costly post-installation modifications.

Advantages of Piloting

Piloting offers the advantage of identifying potential issues and optimizing system performance in a controlled, real-world environment before full-scale implementation. It enables iterative feedback and adjustments, reducing risks and ensuring smoother integration with existing operations. This approach also facilitates stakeholder buy-in through demonstrable results, enhancing overall project success.

When to Choose Commissioning Over Piloting

Choose commissioning over piloting when a system or equipment requires formal validation and integration into operational workflows after installation, ensuring compliance with industry standards and design specifications. Commissioning is essential for complex infrastructure projects like HVAC systems, industrial machinery, or building automation, where full functionality, safety, and performance must be certified before official handover. Piloting is typically reserved for trial phases, whereas commissioning confirms readiness for full-scale use in production environments.

Best Practices for Successful Implementation

Commissioning involves verifying that all systems and components of a project are designed, installed, and functioning according to specifications, while piloting tests the system in a real-world environment to identify and resolve issues before full-scale deployment. Best practices for successful implementation include thorough planning, stakeholder engagement, detailed documentation, and iterative testing to ensure reliability and performance. Combining systematic commissioning with a carefully monitored pilot phase minimizes risks and enhances overall project quality and user acceptance.

Commissioning Infographic

libterm.com

libterm.com