Fluid film contact occurs when a thin layer of lubricant separates two surfaces in relative motion, reducing friction and wear significantly. This type of lubrication is crucial in high-speed machinery and bearing systems, where metal-to-metal contact must be avoided to ensure longevity and efficiency. Explore the rest of the article to learn how fluid film contact optimizes performance and how you can apply its principles to your mechanical systems.

Table of Comparison

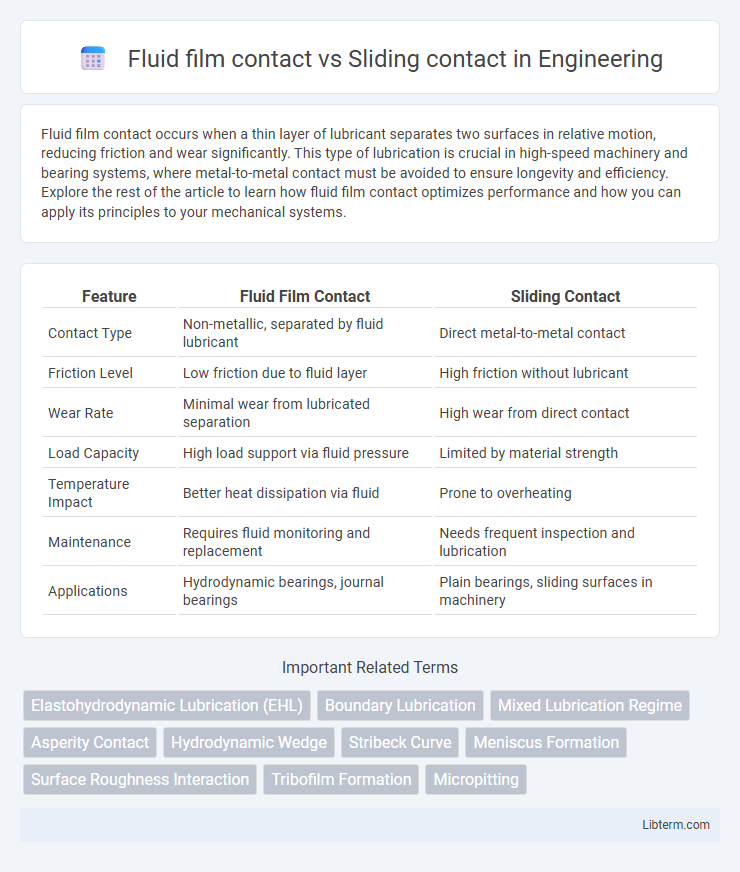

| Feature | Fluid Film Contact | Sliding Contact |

|---|---|---|

| Contact Type | Non-metallic, separated by fluid lubricant | Direct metal-to-metal contact |

| Friction Level | Low friction due to fluid layer | High friction without lubricant |

| Wear Rate | Minimal wear from lubricated separation | High wear from direct contact |

| Load Capacity | High load support via fluid pressure | Limited by material strength |

| Temperature Impact | Better heat dissipation via fluid | Prone to overheating |

| Maintenance | Requires fluid monitoring and replacement | Needs frequent inspection and lubrication |

| Applications | Hydrodynamic bearings, journal bearings | Plain bearings, sliding surfaces in machinery |

Introduction to Contact Mechanics

Fluid film contact involves a lubricating layer that separates surfaces, minimizing direct metal-to-metal interaction and significantly reducing friction and wear in mechanical systems. Sliding contact occurs when surfaces move relative to each other with direct asperity interaction, leading to higher friction and potential surface damage. Understanding these contact modes is essential in contact mechanics to optimize performance and longevity of components such as bearings, gears, and seals.

Defining Fluid Film Contact

Fluid film contact occurs when two surfaces are completely separated by a continuous lubricant layer, preventing direct solid-to-solid contact and minimizing friction and wear. This regime is characterized by hydrodynamic or elastohydrodynamic lubrication where the fluid film thickness exceeds the combined surface roughness, ensuring smooth operation under high-speed or high-load conditions. In contrast, sliding contact involves partial or full metal-to-metal contact, resulting in higher friction, increased wear, and the necessity for boundary or mixed lubrication.

Understanding Sliding Contact

Sliding contact involves direct surface interaction where friction and wear are predominant factors affecting mechanical performance. Unlike fluid film contact, which forms a lubricating layer to reduce metal-to-metal contact, sliding contact relies on boundary or mixed lubrication regimes that minimize damage through protective films or surface treatments. Understanding sliding contact is critical for optimizing bearing design, wear resistance, and improving the longevity of mechanical components subjected to relative motion.

Key Differences Between Fluid Film and Sliding Contact

Fluid film contact involves a lubricating layer that separates two surfaces, minimizing direct metal-to-metal contact and reducing wear and friction. Sliding contact occurs when surfaces move directly against each other without a full lubricating film, resulting in higher friction, increased wear, and potential surface damage. The key difference lies in the presence of a continuous lubricant film in fluid film contact versus direct surface interaction in sliding contact, significantly impacting durability and performance.

Types of Fluid Film Lubrication

Fluid film lubrication is classified into three main types: hydrodynamic, elastohydrodynamic, and hydrostatic lubrication, each providing a continuous fluid film that separates sliding surfaces, preventing direct metal-to-metal contact. Hydrodynamic lubrication relies on relative motion to generate a pressure wedge of lubricant, elastohydrodynamic lubrication occurs in highly loaded contacts with elastic deformation of surfaces, and hydrostatic lubrication uses external pressure to maintain the lubricant film. Sliding contact involves direct asperity interaction, resulting in higher friction and wear compared to the smooth separation achieved by fluid film lubrication types.

Wear and Friction in Sliding Contacts

Sliding contact involves direct surface-to-surface interaction, resulting in higher friction and significant wear due to asperity deformation and material removal. Fluid film contact, by maintaining a lubricating layer between surfaces, drastically reduces friction and wear by preventing metal-to-metal contact. In sliding contacts, optimizing lubrication regimes is essential to minimize wear rates and enhance component longevity in mechanical systems.

Benefits and Limitations of Fluid Film Contact

Fluid film contact, characterized by a continuous lubricant layer separating surfaces, significantly reduces friction and wear compared to sliding contact, where direct surface interaction occurs. This lubrication mechanism enhances machinery lifespan and operational efficiency by minimizing metal-to-metal contact and heat generation. However, fluid film contact relies heavily on maintaining optimal lubricant viscosity and pressure, limiting its effectiveness under extreme loads or start-stop conditions when the lubricant film may break down.

Applications of Fluid Film vs Sliding Contact

Fluid film contact is widely used in high-speed bearings, such as journal and thrust bearings, where a continuous lubricant layer prevents metal-to-metal contact, reducing wear and increasing lifespan in turbines, compressors, and automotive engines. Sliding contact finds applications in situations with low or intermittent lubrication, such as plain bearings, brake pads, and clutch plates, where direct surface interaction is essential for friction and control. Fluid film contact is preferred in high-load, high-speed environments to minimize friction, while sliding contact suits applications requiring controlled friction under variable load conditions.

Material Considerations in Both Contact Types

Material considerations in fluid film contact emphasize high surface finish and compatibility with lubricants to maintain a continuous lubricating film, reducing wear in hydrodynamic or elastohydrodynamic lubrication regimes. In sliding contact, material selection prioritizes wear resistance, hardness, and the ability to withstand adhesive or abrasive interactions due to direct metal-to-metal or material interface contact without a separating fluid layer. Advanced coatings, such as diamond-like carbon (DLC) or solid lubricants like graphite, are often employed in sliding contacts to enhance durability and reduce friction under severe operating conditions.

Future Trends in Contact Mechanics

Future trends in contact mechanics emphasize the integration of fluid film contact principles with advanced materials and surface textures to minimize friction and wear in micro- and nanoscale sliding contacts. Innovations in smart lubricant formulations and adaptive surface coatings enhance the durability and energy efficiency of mechanical systems by maintaining stable fluid films under variable load and speed conditions. Computational modeling combined with real-time sensor data drives the development of predictive maintenance strategies for sliding and fluid film interfaces in aerospace and precision manufacturing industries.

Fluid film contact Infographic

libterm.com

libterm.com