Electrical propulsion offers a clean and efficient alternative to traditional fuel-based engines by using electric energy to power vehicles and spacecraft. This technology reduces emissions and operational costs while enhancing performance through precise control and lower maintenance requirements. Discover how electrical propulsion can transform your approach to transportation by reading the rest of the article.

Table of Comparison

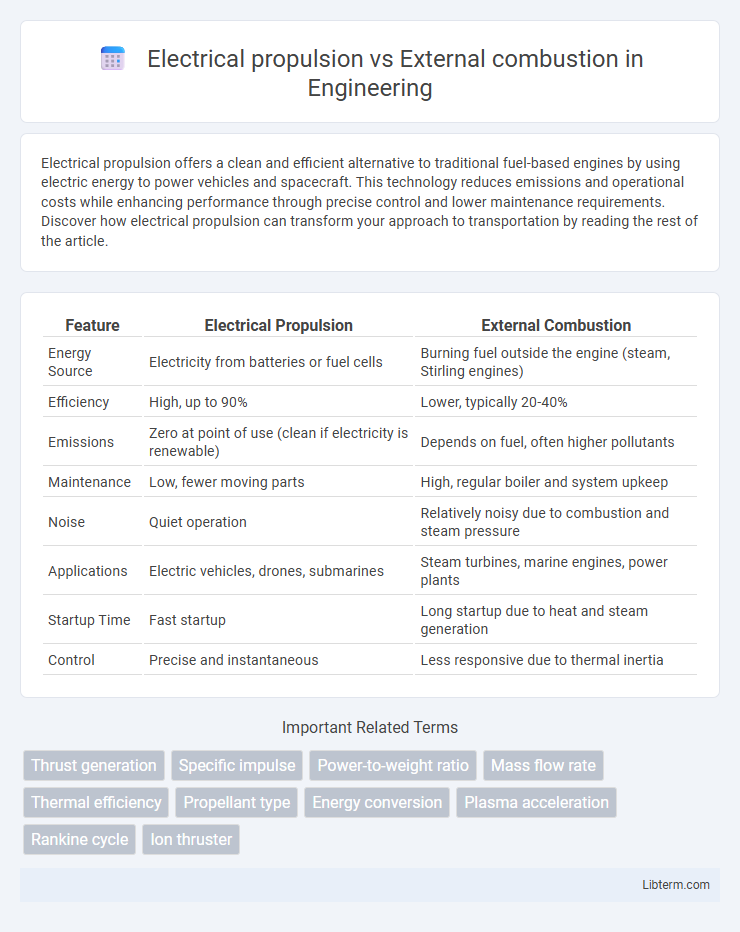

| Feature | Electrical Propulsion | External Combustion |

|---|---|---|

| Energy Source | Electricity from batteries or fuel cells | Burning fuel outside the engine (steam, Stirling engines) |

| Efficiency | High, up to 90% | Lower, typically 20-40% |

| Emissions | Zero at point of use (clean if electricity is renewable) | Depends on fuel, often higher pollutants |

| Maintenance | Low, fewer moving parts | High, regular boiler and system upkeep |

| Noise | Quiet operation | Relatively noisy due to combustion and steam pressure |

| Applications | Electric vehicles, drones, submarines | Steam turbines, marine engines, power plants |

| Startup Time | Fast startup | Long startup due to heat and steam generation |

| Control | Precise and instantaneous | Less responsive due to thermal inertia |

Introduction to Electrical Propulsion and External Combustion

Electrical propulsion systems utilize electric energy to generate thrust, often through electric motors powering propellers or fans, providing high efficiency and precise control ideal for aerospace and marine applications. External combustion engines, such as steam engines, combust fuel outside the engine cylinder to produce steam or hot gases that drive mechanical movement, known for their ability to use diverse fuel sources and maintain consistent power output. The fundamental difference lies in electrical propulsion's direct energy conversion and control capabilities versus the external combustion engine's reliance on thermal energy cycles for mechanical work.

Fundamental Principles of Each Propulsion Method

Electrical propulsion relies on the conversion of electrical energy into mechanical thrust using electric motors and electromagnetic forces, enabling precise control and high efficiency in spacecraft and marine applications. External combustion propulsion generates thrust by burning fuel outside the engine's working fluid system, such as in steam engines or Stirling engines, where heat transfer creates pressure differences for mechanical motion. The fundamental distinction lies in electrical propulsion leveraging electromagnetic fields for movement, while external combustion depends on thermodynamic cycles and heat energy transfer.

Historical Development and Key Innovations

The historical development of electrical propulsion traces back to early 19th-century experiments with electric motors and batteries, culminating in innovations like Thomas Davenport's motor and the introduction of electric streetcars in the late 1800s. External combustion engines evolved from the steam engine, pioneered by James Watt in the 18th century, with key innovations including the Watt governor and high-pressure boilers enhancing efficiency and reliability. Electrical propulsion advanced through battery technology improvements and motor efficiency breakthroughs, while external combustion's progress centered on thermodynamic optimization and fuel versatility.

Efficiency Comparison: Electrical vs External Combustion

Electrical propulsion systems demonstrate significantly higher efficiency compared to external combustion engines, often exceeding 85% energy conversion rates due to direct electrical energy use and minimal mechanical losses. External combustion engines, such as steam engines, typically exhibit lower thermal efficiency, usually around 20-30%, as substantial energy is lost through heat dissipation and multiple energy conversion stages. The superior efficiency of electrical propulsion translates to reduced energy consumption and lower operational costs, making it a preferred choice for modern transportation and industrial applications.

Environmental Impact and Emissions Analysis

Electrical propulsion systems generate zero tailpipe emissions, relying on electricity that can be sourced from renewable energy, thereby significantly reducing greenhouse gas emissions and air pollutants compared to external combustion engines. External combustion engines, such as steam turbines, commonly burn fossil fuels, releasing carbon dioxide, sulfur oxides, and nitrogen oxides that contribute to environmental degradation and respiratory health issues. Life cycle assessments reveal that the environmental benefits of electrical propulsion increase when the electricity grid incorporates higher shares of clean energy, minimizing the overall carbon footprint compared to conventional external combustion propulsion methods.

Maintenance and Operational Costs

Electrical propulsion systems typically offer lower maintenance costs due to fewer moving parts and reduced wear compared to external combustion engines, which require regular servicing of components like boilers and turbines. Operational costs for electrical propulsion benefit from higher energy efficiency and less fuel consumption, whereas external combustion systems often have higher fuel costs and more frequent maintenance intervals. The reliability and longer service intervals of electrical propulsion contribute to overall reduced lifecycle expenses in marine and industrial applications.

Performance Metrics: Power, Speed, and Range

Electrical propulsion systems deliver high torque at low speeds, enabling rapid acceleration and precise speed control with power outputs varying from kilowatts in small vehicles to megawatts in large electric ships. External combustion engines, such as steam turbines, often provide sustained power levels suitable for continuous operation, with lower peak power density but high thermal efficiency in large-scale applications. Range in electrically propelled systems is limited by battery energy density, generally lower than the energy density of fuels used in external combustion engines, which allows for extended operational durations and speeds in heavy-duty transport.

Current Applications in Industry and Transportation

Electrical propulsion dominates modern transportation sectors such as electric vehicles (EVs), rail systems, and aerospace due to its high efficiency, low emissions, and advanced energy storage technologies like lithium-ion batteries. External combustion engines, primarily steam turbines, find widespread industrial applications in power generation, especially in thermal power plants and marine propulsion where fuel flexibility and high power output are essential. Current trends emphasize the transition to electric propulsion in passenger vehicles and urban transport, while external combustion remains integral to large-scale industrial energy systems.

Future Trends and Emerging Technologies

Electrical propulsion systems are rapidly advancing with innovations in high-efficiency electric motors and solid-state batteries, promising greater energy density and reduced emissions compared to traditional external combustion engines. Emerging technologies such as wireless power transfer and integrated AI-driven energy management are enhancing the performance and reliability of electric propulsion in aerospace and automotive sectors. Future trends indicate a strong shift towards electrification combined with renewable energy sources, significantly outpacing the incremental improvements in external combustion engines fueled by biofuels or synthetic fuels.

Conclusion: Choosing the Right Propulsion System

Selecting the optimal propulsion system depends on application-specific requirements such as efficiency, environmental impact, and operational complexity. Electrical propulsion offers high efficiency and zero emissions, making it ideal for sustainable and low-maintenance applications. External combustion engines provide fuel flexibility and simpler fuel sources but tend to have lower efficiency and higher emissions, suitable for contexts where fuel availability and simplicity are prioritized.

Electrical propulsion Infographic

libterm.com

libterm.com