Wear affects both comfort and durability of your clothing, influencing how long garments maintain their appearance and fit. Selecting high-quality fabrics and proper care techniques can significantly reduce wear and extend the lifespan of your wardrobe. Explore the rest of the article to learn practical tips for minimizing wear and keeping your clothes looking fresh.

Table of Comparison

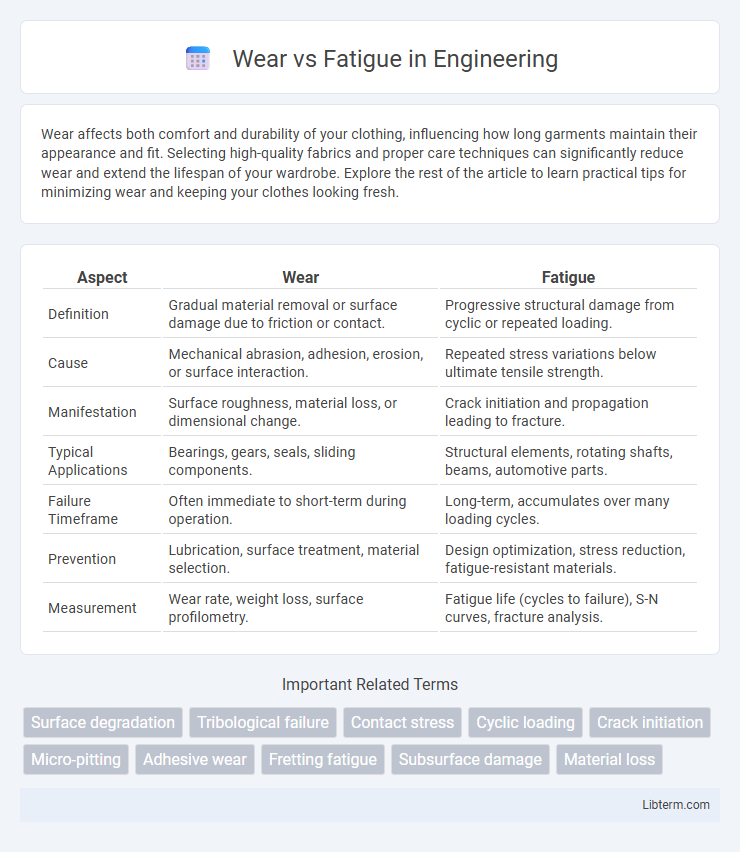

| Aspect | Wear | Fatigue |

|---|---|---|

| Definition | Gradual material removal or surface damage due to friction or contact. | Progressive structural damage from cyclic or repeated loading. |

| Cause | Mechanical abrasion, adhesion, erosion, or surface interaction. | Repeated stress variations below ultimate tensile strength. |

| Manifestation | Surface roughness, material loss, or dimensional change. | Crack initiation and propagation leading to fracture. |

| Typical Applications | Bearings, gears, seals, sliding components. | Structural elements, rotating shafts, beams, automotive parts. |

| Failure Timeframe | Often immediate to short-term during operation. | Long-term, accumulates over many loading cycles. |

| Prevention | Lubrication, surface treatment, material selection. | Design optimization, stress reduction, fatigue-resistant materials. |

| Measurement | Wear rate, weight loss, surface profilometry. | Fatigue life (cycles to failure), S-N curves, fracture analysis. |

Introduction to Wear and Fatigue

Wear refers to the progressive loss of material from a solid surface due to mechanical action such as friction, abrasion, or erosion. Fatigue involves the weakening of a material caused by repeated cyclic stresses, leading to crack initiation and eventual failure. Understanding the fundamental mechanisms of wear and fatigue is essential for predicting the lifespan and maintenance needs of engineering components.

Defining Wear and Its Types

Wear refers to the gradual removal or deformation of material surfaces due to mechanical action, often leading to equipment degradation or failure. Common types of wear include abrasive wear, caused by hard particles or rough surfaces; adhesive wear, resulting from material transfer between contacting surfaces; and corrosive wear, which involves chemical reactions deteriorating the surface. Understanding wear mechanisms is crucial for selecting materials and lubrication strategies that extend component lifespan and ensure system reliability.

Understanding Fatigue in Materials

Fatigue in materials refers to the progressive and localized structural damage that occurs under cyclic loading, even when the stress levels are below the material's ultimate tensile strength. It is characterized by the initiation and growth of cracks, which can ultimately lead to sudden and catastrophic failure. Understanding the mechanisms of fatigue, including crack nucleation, propagation, and the influence of factors such as stress concentration, surface finish, and environmental conditions, is critical for predicting material lifespan and enhancing durability in engineering applications.

Key Differences Between Wear and Fatigue

Wear and fatigue are distinct material degradation mechanisms with wear involving the progressive removal of material due to mechanical action such as friction, while fatigue refers to the initiation and growth of cracks caused by cyclic loading. Wear typically results in surface damage and mass loss, whereas fatigue failure originates internally or on the surface through repeated stress below the ultimate tensile strength. Understanding these differences is crucial for selecting appropriate materials and designing components that can withstand specific operational environments and loading conditions.

Causes of Wear in Engineering Components

Wear in engineering components primarily results from mechanical abrasion, adhesion, surface fatigue, and corrosive reactions. Abrasive wear occurs due to hard particles or asperities causing material removal, while adhesive wear arises from material transfer between contacting surfaces under load. Corrosion accelerates wear through chemical or electrochemical interactions that degrade component surfaces, significantly impacting their operational lifespan.

Factors Influencing Fatigue Failure

Fatigue failure is primarily influenced by factors such as cyclic stress amplitude, stress concentration, and environmental conditions like corrosion, which accelerate crack initiation and propagation in materials. Material properties, including microstructure, hardness, and ductility, also significantly affect fatigue life by determining resistance to crack growth under repeated loading. Manufacturing processes and surface finish quality play crucial roles by introducing defects or residual stresses that act as fatigue crack initiation sites.

Methods for Testing Wear and Fatigue

Testing wear involves methods like pin-on-disk, abrasion, and erosion tests to simulate material loss under frictional contact conditions. Fatigue testing employs techniques such as rotating bending, axial loading, and cantilever beam methods to evaluate material durability under cyclic stresses. Both tests rely on precise measurement of surface degradation and crack initiation to predict lifespan in engineering applications.

Prevention and Mitigation Strategies

Wear and fatigue are critical factors affecting material longevity, with wear involving surface material loss due to friction and fatigue referring to structural failure from repeated stress cycles. Prevention strategies include applying surface treatments like coatings or lubricants to reduce friction and designing components with appropriate stress limits to avoid fatigue initiation. Mitigation involves regular inspections, timely maintenance, and employing advanced materials with higher wear resistance and fatigue strength to enhance durability.

Real-World Applications and Case Studies

Wear and fatigue are critical factors in material degradation, influencing the lifespan of components in industries such as automotive, aerospace, and manufacturing. Real-world applications demonstrate that wear primarily causes surface material loss through abrasion or adhesion, while fatigue results from repeated cyclic stresses leading to crack initiation and propagation. Case studies reveal that combining wear-resistant coatings with fatigue life analysis significantly improves performance and safety in high-stress environments like turbine engines and heavy machinery.

Advances in Materials to Minimize Wear and Fatigue

Advances in materials science have led to the development of high-performance alloys and composite materials with superior wear resistance and fatigue strength, significantly extending the lifespan of mechanical components. Innovations such as nanostructured coatings, self-healing polymers, and surface treatments enhance durability by reducing friction and inhibiting crack propagation under cyclic loading. These breakthroughs optimize maintenance intervals and reliability in critical industries including aerospace, automotive, and manufacturing.

Wear Infographic

libterm.com

libterm.com