Abrasion is a common physical process where the surface layer of a material is worn away due to friction or rubbing against another surface. It plays a significant role in industries like manufacturing, construction, and geology, affecting the durability and lifespan of tools, structures, and natural formations. Explore the rest of the article to understand how abrasion impacts various materials and ways to protect against it.

Table of Comparison

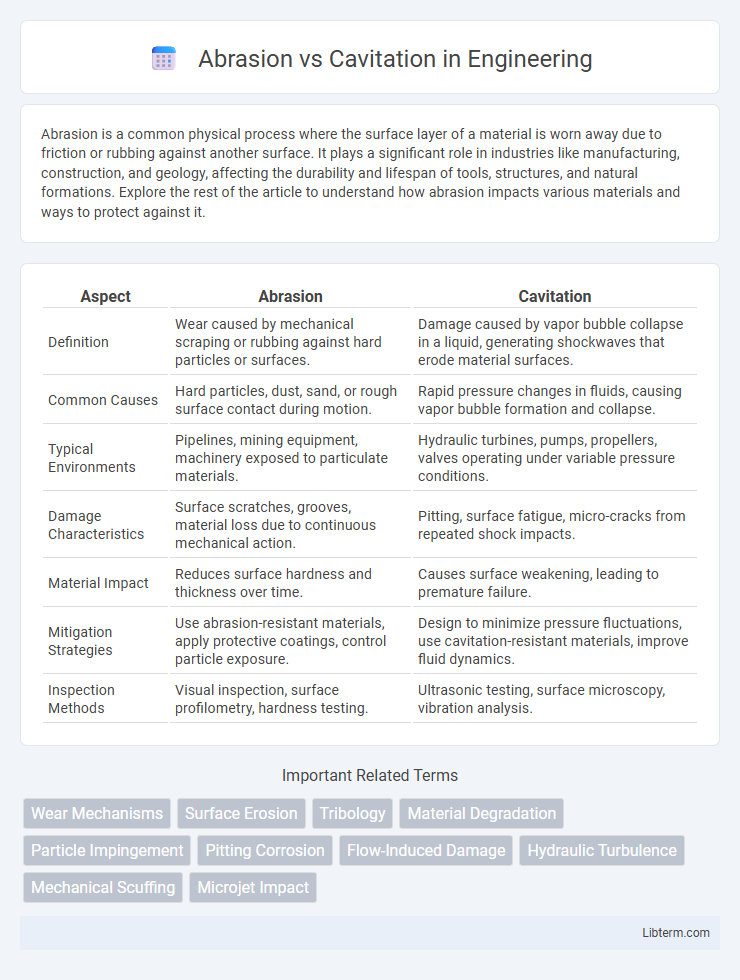

| Aspect | Abrasion | Cavitation |

|---|---|---|

| Definition | Wear caused by mechanical scraping or rubbing against hard particles or surfaces. | Damage caused by vapor bubble collapse in a liquid, generating shockwaves that erode material surfaces. |

| Common Causes | Hard particles, dust, sand, or rough surface contact during motion. | Rapid pressure changes in fluids, causing vapor bubble formation and collapse. |

| Typical Environments | Pipelines, mining equipment, machinery exposed to particulate materials. | Hydraulic turbines, pumps, propellers, valves operating under variable pressure conditions. |

| Damage Characteristics | Surface scratches, grooves, material loss due to continuous mechanical action. | Pitting, surface fatigue, micro-cracks from repeated shock impacts. |

| Material Impact | Reduces surface hardness and thickness over time. | Causes surface weakening, leading to premature failure. |

| Mitigation Strategies | Use abrasion-resistant materials, apply protective coatings, control particle exposure. | Design to minimize pressure fluctuations, use cavitation-resistant materials, improve fluid dynamics. |

| Inspection Methods | Visual inspection, surface profilometry, hardness testing. | Ultrasonic testing, surface microscopy, vibration analysis. |

Understanding Abrasion and Cavitation

Abrasion refers to the mechanical wearing down of material surfaces caused by friction or contact with hard particles, often leading to surface roughness and erosion in industrial components. Cavitation occurs when rapid pressure changes in a liquid create vapor bubbles that implode violently, causing localized microjets and shockwaves that damage metal surfaces. Understanding the distinct mechanisms of abrasion and cavitation is crucial for selecting appropriate materials and protective coatings to enhance equipment durability and performance in fluid environments.

Definition of Abrasion

Abrasion is the mechanical process of wear caused by friction between surfaces, typically involving hard particles or rough materials scraping against a softer surface. This form of surface degradation results in material loss and reduced structural integrity, commonly seen in industrial machinery, pipelines, and coatings. Unlike cavitation, which is driven by vapor bubble implosions, abrasion primarily stems from direct physical contact and mechanical action.

Definition of Cavitation

Cavitation is the formation and collapse of vapor bubbles in a liquid caused by rapid changes in pressure, typically occurring near pump impellers or propeller blades. This phenomenon generates intense shock waves that can cause significant material damage and surface pitting. Unlike abrasion, which involves mechanical wear due to friction or particle impact, cavitation specifically results from vapor bubble dynamics in fluid environments.

Causes of Abrasion

Abrasion occurs primarily due to the mechanical scraping or wearing away of a surface caused by friction between abrasive particles and the material. Common causes include the presence of hard particles like sand, dust, or grit in fluids or on surfaces, which grind against equipment or surfaces, leading to material loss. The intensity of abrasion depends on factors such as particle size, hardness, concentration, and the velocity of the moving medium.

Causes of Cavitation

Cavitation is primarily caused by the formation and collapse of vapor bubbles in a liquid when local pressure drops below the vapor pressure, often due to changes in flow velocity or pressure within pumps, propellers, or valves. This phenomenon typically occurs in areas of high turbulence and rapid pressure fluctuations, leading to localized damage on metal surfaces as the vapor bubbles implode. Unlike abrasion, which involves direct mechanical wear from solid particles, cavitation results from fluid dynamic forces causing micro-jet impacts and shock waves that erode material surfaces.

Distinctive Features: Abrasion vs Cavitation

Abrasion primarily involves the mechanical wearing away of a surface caused by friction from particles or rough materials, leading to gradual material loss and surface roughness. Cavitation results from the formation and implosion of vapor bubbles in a fluid, causing intense localized pressure and surface pitting or erosion on materials submerged in liquid. The key distinction lies in abrasion being a solid-solid contact phenomenon, while cavitation is a fluid dynamic effect causing damage through micro-jet impacts and shock waves.

Impact on Equipment and Materials

Abrasion causes surface wear and progressive material loss due to friction or contact with hard particles, leading to thinning and eventual failure of components such as pipes, pumps, and turbines. Cavitation generates intense localized pressure fluctuations and shock waves from vapor bubble collapse, resulting in pitting, surface erosion, and compromised structural integrity in hydraulic machinery and propellers. Both mechanisms accelerate equipment degradation, increase maintenance costs, and reduce operational lifespan by undermining material strength and surface smoothness.

Detection and Diagnosis Methods

Abrasion detection primarily relies on visual inspection techniques, including microscopy to identify surface wear patterns and material loss on components. Cavitation diagnosis utilizes ultrasonic testing and acoustic emission analysis to detect characteristic bubble collapse noises and surface pitting caused by vapor bubble implosions. Advanced methods such as scanning electron microscopy (SEM) and vibration analysis enhance accuracy in distinguishing between abrasion wear and cavitation damage in industrial machinery.

Prevention and Mitigation Strategies

Abrasion prevention focuses on using wear-resistant materials such as hardened steel or ceramics and implementing protective coatings like polyurethane or rubber liners to reduce surface damage from friction and particulate matter. Cavitation mitigation relies on design modifications that minimize pressure fluctuations, including increasing pipe diameter, smoothing flow paths, and using anti-cavitation valve trims to prevent bubble formation and collapse. Routine maintenance, real-time monitoring with vibration sensors, and timely replacement of damaged components are essential strategies to extend equipment lifespan and ensure operational efficiency.

Choosing the Right Solution for Wear Problems

Selecting the right solution for wear problems involves understanding the distinct causes and effects of abrasion and cavitation. Abrasion occurs due to hard particles or rough surfaces causing mechanical wear, best managed using wear-resistant coatings or hardened materials, while cavitation results from vapor bubble collapse in fluids, requiring design modifications like improved fluid flow or cavitation-resistant materials. Implementing targeted treatments based on accurate diagnosis optimizes equipment lifespan and performance by addressing the specific wear mechanism effectively.

Abrasion Infographic

libterm.com

libterm.com