Shielded metal arc welding (SMAW) is a versatile and widely used welding process that employs a consumable electrode coated with flux to create a strong, durable weld. This method is highly effective for joining ferrous metals and is favored for its simplicity, portability, and cost-efficiency in various industrial applications. Enhance Your welding knowledge and skills by exploring the detailed insights and techniques outlined in the rest of this article.

Table of Comparison

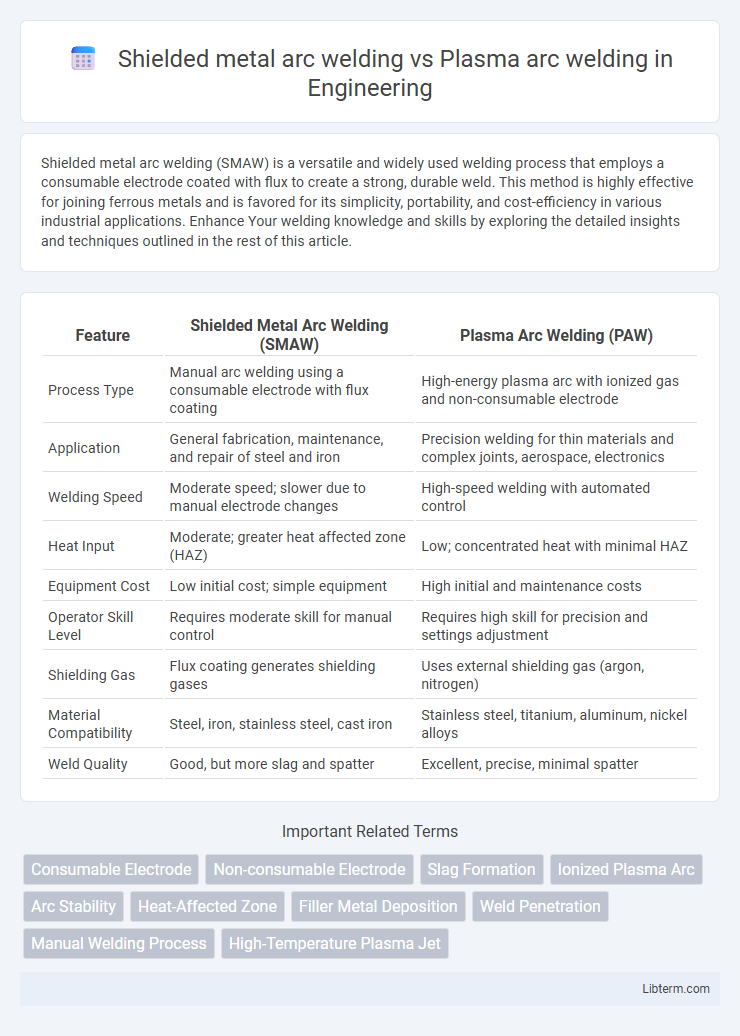

| Feature | Shielded Metal Arc Welding (SMAW) | Plasma Arc Welding (PAW) |

|---|---|---|

| Process Type | Manual arc welding using a consumable electrode with flux coating | High-energy plasma arc with ionized gas and non-consumable electrode |

| Application | General fabrication, maintenance, and repair of steel and iron | Precision welding for thin materials and complex joints, aerospace, electronics |

| Welding Speed | Moderate speed; slower due to manual electrode changes | High-speed welding with automated control |

| Heat Input | Moderate; greater heat affected zone (HAZ) | Low; concentrated heat with minimal HAZ |

| Equipment Cost | Low initial cost; simple equipment | High initial and maintenance costs |

| Operator Skill Level | Requires moderate skill for manual control | Requires high skill for precision and settings adjustment |

| Shielding Gas | Flux coating generates shielding gases | Uses external shielding gas (argon, nitrogen) |

| Material Compatibility | Steel, iron, stainless steel, cast iron | Stainless steel, titanium, aluminum, nickel alloys |

| Weld Quality | Good, but more slag and spatter | Excellent, precise, minimal spatter |

Introduction to Shielded Metal Arc Welding (SMAW) and Plasma Arc Welding (PAW)

Shielded Metal Arc Welding (SMAW) utilizes a consumable electrode coated with flux to produce a shielding gas and slag, protecting the weld from atmospheric contamination, making it ideal for outdoor and construction applications. Plasma Arc Welding (PAW) employs a high-velocity ionized gas plasma to generate concentrated heat, enabling precise and deep welds, commonly used in aerospace and intricate metal fabrication. Both processes offer distinct benefits, with SMAW favored for versatility and PAW for precision and speed in high-quality welds.

Process Overview: SMAW vs PAW

Shielded Metal Arc Welding (SMAW) uses a consumable electrode coated with flux to create an electric arc between the electrode and the workpiece, forming a weld pool protected by the flux-generated shielding gas and slag. Plasma Arc Welding (PAW) employs a high-velocity ionized gas (plasma) directed through a fine nozzle, producing a concentrated arc that melts the base metal with precise heat control and minimal filler material use. SMAW is versatile for outdoor and heavy-duty applications, while PAW offers higher precision and cleaner welds ideal for thin materials and intricate tasks.

Equipment and Setup Differences

Shielded metal arc welding (SMAW) utilizes a consumable electrode coated with flux, requiring basic power sources typically delivering 20-300 amps and portable, straightforward equipment suitable for outdoor or fieldwork. Plasma arc welding (PAW) employs a non-consumable tungsten electrode with a separate plasma gas supply and a specialized torch, demanding precise control units, high-frequency starters, and often more complex, stationary setups for clean, high-precision welds. The equipment complexity and setup time in PAW are significantly higher than SMAW, reflecting its suitability for detailed industrial applications versus SMAW's versatility and ease of use.

Types of Electrodes and Consumables Used

Shielded Metal Arc Welding (SMAW) utilizes flux-coated consumable electrodes that provide a protective gas shield and slag layer, critical for preventing oxidation and contamination during welding. In contrast, Plasma Arc Welding (PAW) employs non-consumable tungsten electrodes, with shielding achieved through a controlled plasma gas, often argon or nitrogen, offering precise and high-temperature arcs ideal for detailed welds. SMAW electrodes vary in composition, such as cellulose or low-hydrogen coatings, tailored for specific metals and applications, while PAW consumables include filler rods selected based on the base material and welding requirements.

Applications and Suitability

Shielded metal arc welding (SMAW) is widely suited for heavy steel construction, shipbuilding, and maintenance work due to its portability and ability to weld thick materials in outdoor or rugged environments. Plasma arc welding (PAW) excels in precision industries such as aerospace and automotive manufacturing, offering superior control and high-quality welds on thin or specialized metals. SMAW is preferred for versatility and fieldwork, while PAW is ideal for applications demanding fine detail and consistent weld quality.

Welding Quality and Precision

Shielded Metal Arc Welding (SMAW) offers versatility and strong weld quality for thick metals but often results in lower precision due to slag formation and potential weld spatter. Plasma Arc Welding (PAW) delivers superior precision and cleaner welds with a highly concentrated arc, enabling finer control over heat and weld penetration, which improves joint quality, especially in delicate or thin materials. The enhanced control in PAW reduces distortion and defects, making it ideal for applications requiring exacting weld quality and precision.

Speed and Efficiency Comparison

Shielded Metal Arc Welding (SMAW) is generally slower due to manual electrode handling and frequent stops for electrode replacement, resulting in lower deposition rates compared to Plasma Arc Welding (PAW). Plasma Arc Welding offers higher welding speeds and greater efficiency by utilizing a concentrated plasma jet, enabling deeper penetration and faster welding with minimal filler material. PAW's automation capability further enhances productivity, making it more suitable for high-volume industrial applications than the labor-intensive SMAW process.

Cost Considerations and Investment

Shielded metal arc welding (SMAW) requires lower initial investment costs and minimal equipment, making it cost-effective for small-scale or maintenance applications. Plasma arc welding (PAW) demands higher upfront expenses due to specialized power sources and precise equipment, but offers increased efficiency and precision for industrial-scale production. Long-term operational costs for PAW offset its investment through faster welding speeds and improved weld quality, reducing rework and material waste.

Safety Measures and Risks

Shielded Metal Arc Welding (SMAW) poses risks such as electric shock, harmful fumes, and ultraviolet radiation exposure, necessitating personal protective equipment (PPE) like insulated gloves, welding helmets, and proper ventilation systems to mitigate hazards. Plasma Arc Welding (PAW) requires stringent control of high-temperature plasma and intense ultraviolet light, with safety measures including flame-resistant clothing, eye protection with specialized lenses, and effective exhaust ventilation to prevent respiratory issues from toxic gases. Both methods demand adherence to welding safety standards outlined by OSHA and regular equipment inspections to minimize accident risks and ensure operator safety.

Choosing the Right Welding Method

Shielded metal arc welding (SMAW) excels in versatility and cost-effectiveness, making it ideal for outdoor repairs and heavy-duty construction projects, especially with thick metals and varying positions. Plasma arc welding (PAW) offers superior precision and control, suited for high-quality, clean welds on thin materials or intricate components in aerospace and electronics industries. Selecting the right welding method depends on factors such as metal thickness, required weld quality, working environment, and budget constraints.

Shielded metal arc welding Infographic

libterm.com

libterm.com