Clearance fit ensures that there is always a gap between mating parts, allowing for easy assembly and movement without interference. This type of fit is commonly used in applications where components must slide or rotate freely, such as in bearings or shafts. Explore this article to understand how clearance fits influence your mechanical designs and improve functionality.

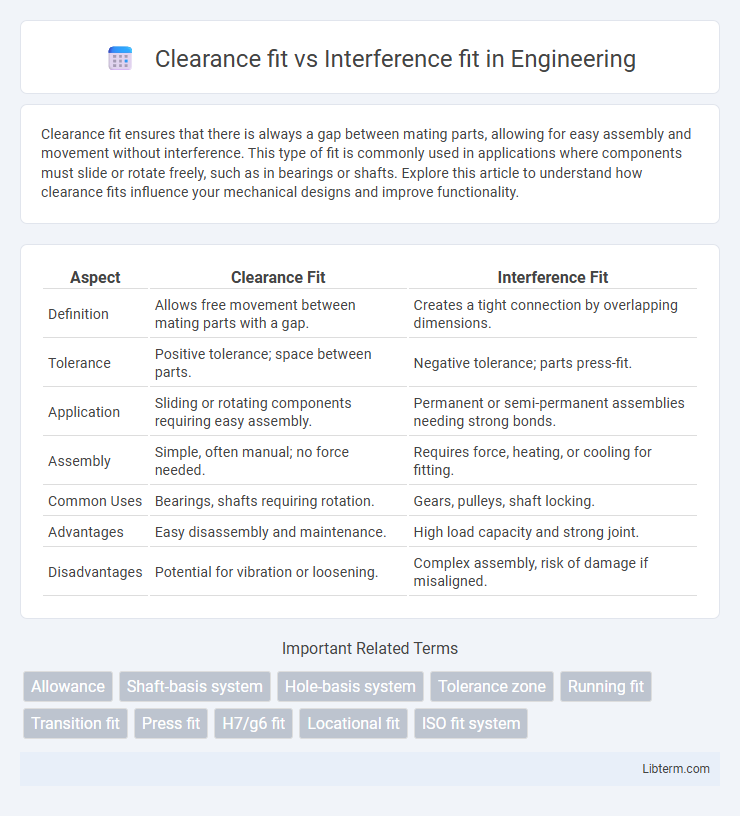

Table of Comparison

| Aspect | Clearance Fit | Interference Fit |

|---|---|---|

| Definition | Allows free movement between mating parts with a gap. | Creates a tight connection by overlapping dimensions. |

| Tolerance | Positive tolerance; space between parts. | Negative tolerance; parts press-fit. |

| Application | Sliding or rotating components requiring easy assembly. | Permanent or semi-permanent assemblies needing strong bonds. |

| Assembly | Simple, often manual; no force needed. | Requires force, heating, or cooling for fitting. |

| Common Uses | Bearings, shafts requiring rotation. | Gears, pulleys, shaft locking. |

| Advantages | Easy disassembly and maintenance. | High load capacity and strong joint. |

| Disadvantages | Potential for vibration or loosening. | Complex assembly, risk of damage if misaligned. |

Introduction to Clearance Fit and Interference Fit

Clearance fit allows parts to slide or move freely due to intentional space between mating components, ensuring easy assembly and disassembly. Interference fit involves parts designed to be slightly larger than the mating hole, creating a tight, friction-based connection that prevents movement. Both fits are critical in mechanical design for controlling tolerance, alignment, and load distribution in assemblies.

Definition of Clearance Fit

Clearance fit occurs when the smallest shaft diameter is always smaller than the largest hole diameter, ensuring a guaranteed space or clearance between the mating parts for easy assembly. This type of fit allows free movement of components and is commonly used in applications where parts must slide or rotate smoothly. In contrast, interference fit involves the shaft being larger than the hole, creating a tight or press fit without any clearance.

Definition of Interference Fit

Interference fit, also known as a press fit or friction fit, occurs when the mating parts are designed with dimensions that cause them to overlap, resulting in a tight and secure connection without the need for additional fasteners. The material deformation under pressure creates a strong bond that resists movement, making it ideal for applications requiring high load transmission and durability. Unlike clearance fit, which allows free movement between parts, interference fit ensures a fixed, stable assembly essential in precision engineering and heavy-duty machinery.

Key Differences Between Clearance and Interference Fits

Clearance fit allows for free movement between mating parts, with the shaft diameter always smaller than the hole diameter, ensuring easy assembly and disassembly. Interference fit creates a tight assembly by having the shaft diameter slightly larger than the hole diameter, resulting in a press or shrink fit that requires force or heating for installation. The key difference lies in the relationship between shaft and hole sizes, where clearance fits prioritize movement and ease of assembly, while interference fits focus on creating a secure and rigid connection.

Applications of Clearance Fit

Clearance fit is commonly used in applications where easy assembly and disassembly are required, such as in bearings, sliding parts, and housings. It allows for free movement between components while maintaining alignment, making it ideal for machine tools, shafts, and couplings. This fit ensures smooth operation without causing stress or deformation due to tight pressure.

Applications of Interference Fit

Interference fit is commonly applied in mechanical engineering to achieve strong, permanent joints between components such as gears, bearings, and shafts, where high load transmission and resistance to relative motion are critical. This fit is ideal for applications requiring precise alignment and stability under heavy stresses, for example, in automotive and aerospace assemblies, heavy machinery, and electrical motors. Interference fit ensures enhanced performance by utilizing material elasticity to create a tight, secure bond without needing additional fasteners.

Advantages of Clearance Fit

Clearance fit offers the advantage of easy assembly and disassembly due to the intentional gap between mating parts, reducing wear and extending component life. It enables smooth motion and alignment accuracy, essential in applications requiring frequent maintenance or adjustments. This fit type also accommodates thermal expansion and manufacturing tolerances, minimizing the risk of jamming or seizing.

Advantages of Interference Fit

Interference fit offers superior load-carrying capacity and resistance to relative motion between mating parts, enhancing mechanical stability in high-stress applications. The tight joint formed by interference fit improves vibration damping and reduces the risk of component loosening, which is crucial in automotive and aerospace engineering. This fit type also ensures precise alignment and support under thermal and dynamic loads, increasing the lifespan of mechanical assemblies.

Factors Influencing Fit Selection

Factors influencing fit selection include load conditions, thermal expansion, and assembly methods. Clearance fits are preferred for applications requiring easy assembly and disassembly, while interference fits provide high load capacity and resistance to vibration. Material properties, surface finish, and operating environment also play critical roles in determining the appropriate fit type.

Summary: Choosing Between Clearance and Interference Fit

Clearance fit provides a gap between mating parts, allowing easy assembly and movement, ideal for applications requiring frequent disassembly or thermal expansion accommodation. Interference fit creates a tight, pressurized joint where parts are slightly larger than the mating hole, ensuring strong, permanent connections used in high-load or high-precision environments. Selecting between clearance and interference fits depends on the balance between assembly ease, operational requirements, and the need for rigidity or flexibility in mechanical systems.

Clearance fit Infographic

libterm.com

libterm.com