Spherical roller bearings excel in handling heavy radial loads and moderate axial loads, making them ideal for applications with misalignment or shaft deflection. Their robust design ensures durability and reliability in harsh operating conditions, contributing to longer equipment life and reduced maintenance costs. Discover how these bearings can enhance Your machinery's performance by exploring the full article.

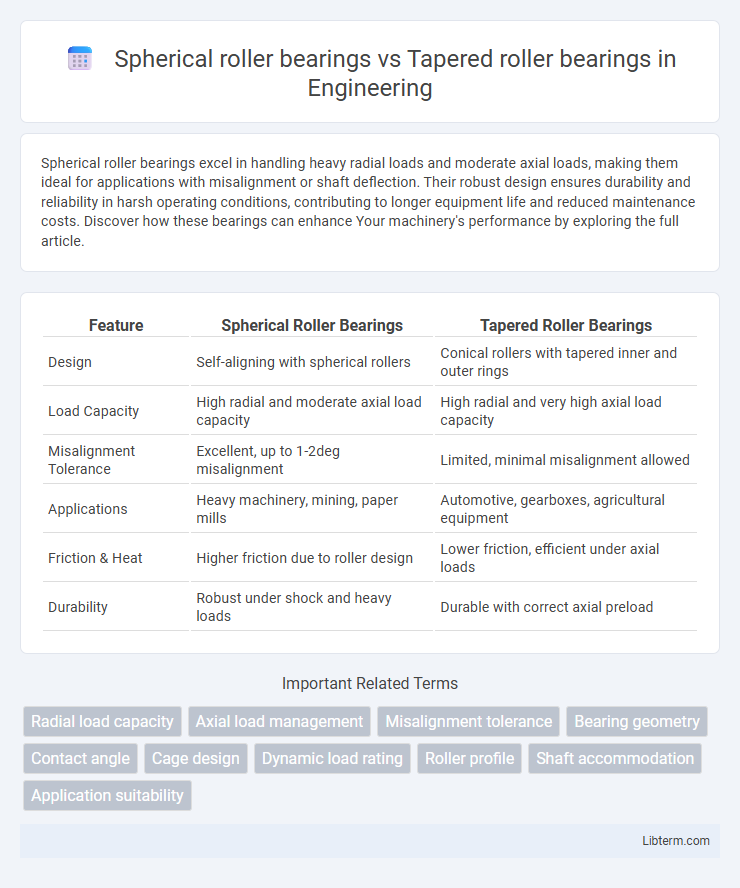

Table of Comparison

| Feature | Spherical Roller Bearings | Tapered Roller Bearings |

|---|---|---|

| Design | Self-aligning with spherical rollers | Conical rollers with tapered inner and outer rings |

| Load Capacity | High radial and moderate axial load capacity | High radial and very high axial load capacity |

| Misalignment Tolerance | Excellent, up to 1-2deg misalignment | Limited, minimal misalignment allowed |

| Applications | Heavy machinery, mining, paper mills | Automotive, gearboxes, agricultural equipment |

| Friction & Heat | Higher friction due to roller design | Lower friction, efficient under axial loads |

| Durability | Robust under shock and heavy loads | Durable with correct axial preload |

Introduction to Spherical and Tapered Roller Bearings

Spherical roller bearings feature two rows of rollers that allow for angular misalignment and are designed to handle heavy radial loads as well as moderate axial loads in both directions. Tapered roller bearings have conical rollers and raceways, optimized for managing combined radial and axial loads, especially supporting high axial forces in one direction. Both bearing types are essential in industrial applications requiring durability and high load-carrying capacity, yet their structural differences tailor them to specific load and alignment conditions.

Design Differences: Spherical vs Tapered Roller Bearings

Spherical roller bearings feature two rows of rollers with a common spherical outer raceway, enabling them to accommodate misalignment and axial loads in both directions. Tapered roller bearings consist of tapered inner and outer raceways with conical rollers, designed primarily for combined radial and axial loads but are sensitive to alignment errors. The design difference impacts load capacity, misalignment tolerance, and typical applications, with spherical bearings excelling in heavy-duty, misalignment-prone environments and tapered bearings optimizing thrust and radial load handling in precise alignment conditions.

Load Handling Capabilities

Spherical roller bearings excel in handling heavy radial loads and moderate axial loads, thanks to their self-aligning design that compensates for shaft misalignment and shaft deflection. Tapered roller bearings are specifically engineered to manage combined radial and axial loads with greater axial load capacity due to their conical geometry. In applications requiring high axial rigidity and load support, tapered roller bearings outperform spherical rollers, while spherical roller bearings provide superior performance in conditions with shaft misalignment and heavy radial load demands.

Misalignment Tolerance Comparison

Spherical roller bearings exhibit superior misalignment tolerance due to their self-aligning design, accommodating angular misalignments up to 1deg to 2deg, which reduces stress and extends bearing life. In contrast, tapered roller bearings have limited misalignment capacity, typically less than 0.5deg, making them more susceptible to premature wear and failure under misalignment conditions. Therefore, spherical roller bearings are preferred in applications prone to shaft deflections and housing misalignments.

Axial and Radial Load Support

Spherical roller bearings excel in accommodating high radial loads and moderate axial loads due to their barrel-shaped rollers and self-aligning design, which also compensates for shaft misalignments. Tapered roller bearings provide superior axial load support in one direction alongside substantial radial load capacity, owing to their conical rolling elements and contact angle geometry. Selecting between these bearings depends on the specific load directions, with spherical designs favored for heavy radial plus moderate axial loads and tapered rollers prioritized where significant axial load resistance and precise shaft positioning are required.

Applications and Industry Use Cases

Spherical roller bearings excel in applications with heavy radial loads and moderate misalignment, commonly used in industries such as mining, construction, and paper mills where shaft deflections occur. Tapered roller bearings handle combined radial and axial loads, making them ideal for automotive wheel hubs, gearboxes, and agricultural machinery requiring precise alignment and load distribution. Both bearing types are critical in heavy-duty machinery, but spherical bearings suit environments with shaft misalignment, while tapered bearings perform best under axial load and high-speed conditions.

Maintenance and Lifespan Factors

Spherical roller bearings require less frequent maintenance due to their ability to accommodate misalignment and heavy loads, which reduces stress and wear on components, extending their lifespan. Tapered roller bearings, while offering excellent axial and radial load handling, demand more precise alignment and regular lubrication to prevent premature failure. Proper maintenance, including monitoring lubrication quality and alignment accuracy, significantly influences the operational longevity of both bearing types.

Installation and Mounting Considerations

Spherical roller bearings require careful alignment during installation to accommodate shaft deflections and misalignments, with mounting methods often involving locating rings or adapters to maintain proper internal clearance. Tapered roller bearings demand precise axial positioning and preload adjustments, typically installed as matched pairs to handle combined radial and axial loads efficiently. Proper lubrication and shaft/housing fit tolerances are critical for both types to ensure optimal performance and longevity in their respective applications.

Cost Analysis and Economic Efficiency

Spherical roller bearings typically offer higher upfront costs due to their complex design and enhanced load-carrying capacity, making them ideal for heavy-duty applications with misalignment issues. Tapered roller bearings generally have lower initial costs and excel in handling combined radial and axial loads, providing cost-effective solutions for moderate load conditions. Economic efficiency depends on the specific application requirements, where spherical bearings reduce long-term maintenance expenses in harsh environments, while tapered bearings deliver optimal performance and cost savings in precision machinery.

Choosing the Right Bearing for Your Application

Spherical roller bearings excel in accommodating heavy radial loads and moderate axial loads while compensating for misalignment, making them ideal for applications with shaft deflection or housing distortion. Tapered roller bearings are designed to handle combined radial and axial loads efficiently, especially in high-speed or precise alignment scenarios such as automotive wheel hubs and gearboxes. Selecting the right bearing depends on load type, shaft alignment, speed requirements, and operating conditions to ensure optimal performance and longevity.

Spherical roller bearings Infographic

libterm.com

libterm.com