Plug flow and mixed flow are two fundamental models used to describe fluid movement in reactors and pipelines, each with distinct flow characteristics that impact mixing and reaction efficiency. Plug flow assumes a uniform velocity profile with no back-mixing, ideal for processes requiring sequential reactions and minimal dispersion, while mixed flow models represent complete mixing with uniform composition throughout the reactor. Explore the article to understand how these flow patterns influence your system design and process optimization.

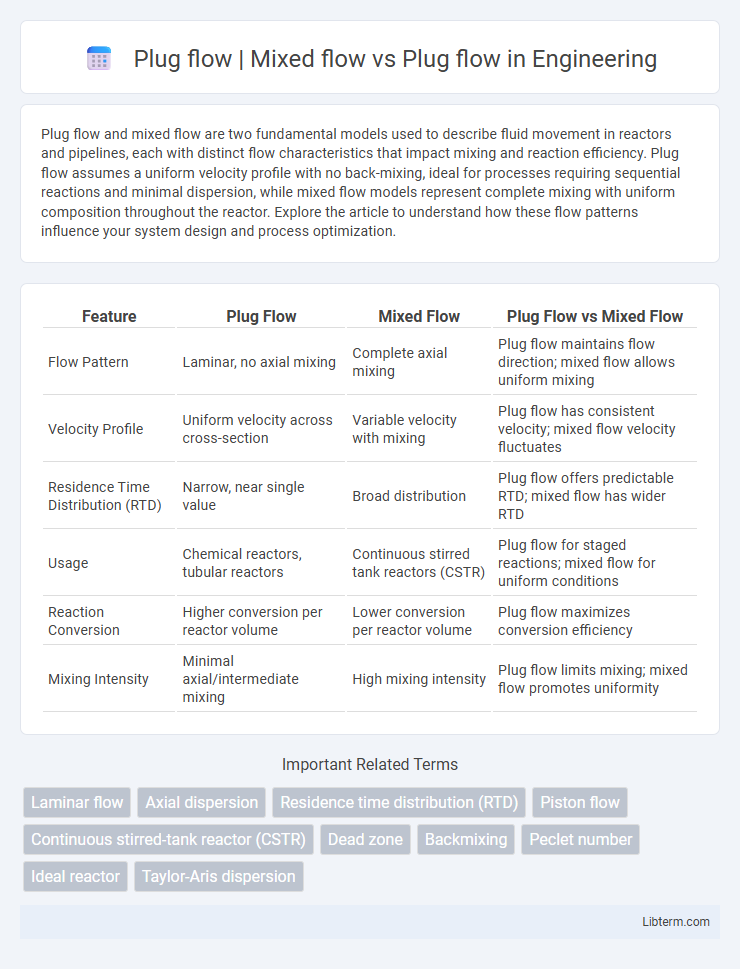

Table of Comparison

| Feature | Plug Flow | Mixed Flow | Plug Flow vs Mixed Flow |

|---|---|---|---|

| Flow Pattern | Laminar, no axial mixing | Complete axial mixing | Plug flow maintains flow direction; mixed flow allows uniform mixing |

| Velocity Profile | Uniform velocity across cross-section | Variable velocity with mixing | Plug flow has consistent velocity; mixed flow velocity fluctuates |

| Residence Time Distribution (RTD) | Narrow, near single value | Broad distribution | Plug flow offers predictable RTD; mixed flow has wider RTD |

| Usage | Chemical reactors, tubular reactors | Continuous stirred tank reactors (CSTR) | Plug flow for staged reactions; mixed flow for uniform conditions |

| Reaction Conversion | Higher conversion per reactor volume | Lower conversion per reactor volume | Plug flow maximizes conversion efficiency |

| Mixing Intensity | Minimal axial/intermediate mixing | High mixing intensity | Plug flow limits mixing; mixed flow promotes uniformity |

Introduction to Flow Regimes in Reactors

Plug flow reactors (PFRs) exhibit idealized flow where fluid elements move through the reactor in a "plug," maintaining uniform velocity and no back-mixing, ensuring high conversion efficiency in chemical processes. Mixed flow reactors, or continuous stirred-tank reactors (CSTRs), feature complete mixing, resulting in uniform composition throughout the reactor but lower conversion per volume compared to PFRs. Understanding flow regimes in reactors is essential for optimizing reaction kinetics, residence time distribution, and overall reactor design in chemical engineering applications.

What is Plug Flow?

Plug flow refers to a fluid flow pattern in which all fluid particles move parallel to each other and have uniform velocity, with no mixing in the flow direction. Unlike mixed flow, where complete mixing occurs resulting in uniform properties throughout the reactor, plug flow maintains a distinct gradient in concentration or temperature along the flow path. This characteristic makes plug flow ideal for chemical reactors where precise control over reaction time and conversion is required.

Key Characteristics of Plug Flow

Plug flow is characterized by fluid particles moving through a reactor in unidirectional, parallel layers with minimal axial mixing, resulting in a uniform residence time. This contrasts with mixed flow, where complete mixing occurs, leading to a broad residence time distribution and lower reaction efficiency. Key parameters defining plug flow include high Peclet number, sharp concentration gradients perpendicular to flow, and predictable conversion rates due to idealized laminar flow behavior.

Understanding Mixed Flow Dynamics

Mixed flow dynamics involve a combination of plug flow and complete mixing, where fluid elements experience varying residence times, unlike the uniform velocity profile in pure plug flow. In mixed flow reactors, concentration gradients and back-mixing influence reaction rates and product distribution, complicating kinetic modeling compared to ideal plug flow systems. Understanding these dynamics is essential for optimizing industrial processes such as chemical reactors and wastewater treatment, where achieving desired conversion and selectivity depends on controlling flow patterns.

Plug Flow vs Mixed Flow: Core Differences

Plug flow reactors exhibit a unidirectional, laminar flow where fluid particles move in parallel paths with minimal back-mixing, ensuring uniform residence time throughout the system. Mixed flow reactors, or continuous stirred-tank reactors (CSTR), feature complete mixing of reactants, resulting in a homogeneous composition and variable residence times for fluid elements. The core difference lies in the flow pattern and mixing behavior: plug flow maintains a gradient in concentration along the reactor length, whereas mixed flow achieves instantaneous mixing and uniform composition at all points.

Advantages of Plug Flow Reactors

Plug flow reactors (PFRs) offer superior conversion efficiency due to their characteristic of maintaining a uniform velocity profile and minimal back-mixing, ensuring that reactants move through the reactor as discrete "plugs." This leads to higher product yields and better control over reaction time compared to mixed flow reactors, where continuous mixing causes concentration gradients and limits conversion per pass. PFRs excel in processes requiring precise temperature and reaction time management, enhancing overall process performance and scalability.

Mixed Flow Reactor Benefits and Limitations

Mixed flow reactors provide uniform concentration and temperature throughout the reactor, ensuring consistent reaction conditions and easier control compared to plug flow reactors. Their main benefits include efficient mixing, which prevents concentration gradients, and suitability for liquid-phase reactions with solids or gases. However, limitations arise from back-mixing that reduces conversion efficiency for fast reactions and larger reactor volumes required to achieve comparable conversion to plug flow reactors.

Applications of Plug Flow and Mixed Flow Reactors

Plug flow reactors (PFRs) find extensive application in chemical processes requiring precise control over reaction time and conversion, such as in polymerization and catalytic oxidation. Mixed flow reactors (MFRs), also known as continuous stirred-tank reactors (CSTRs), are widely used in wastewater treatment and fermentation, where uniform composition and temperature throughout the reactor are critical. Industrial applications benefit from PFRs when plug flow behavior enhances selectivity and conversion, while MFRs are preferred for reactions needing thorough mixing and steady-state conditions.

Factors Influencing Flow Choice in Industry

The choice between plug flow and mixed flow reactors in industry is influenced by factors such as reaction kinetics, desired residence time distribution, and mixing requirements. Plug flow reactors offer uniform residence time ideal for fast, irreversible reactions, while mixed flow reactors provide thorough mixing suited for slower or reversible reactions. Process scale, fluid properties, and cost also play critical roles in determining the optimal flow regime for efficient production.

Conclusion: Selecting the Optimal Reactor Flow Type

Selecting the optimal reactor flow type depends on the specific chemical process and desired product quality; plug flow reactors (PFR) offer uniform residence time, ideal for high conversion and selectivity in reactions sensitive to concentration gradients. Mixed flow reactors (CSTR) provide complete mixing and uniform composition, suitable for reactions requiring consistent temperature and easy scale-up, but may result in lower conversion per volume. Evaluating reaction kinetics, heat transfer requirements, and scale informs the choice between plug flow and mixed flow to maximize efficiency and output.

Plug flow | Mixed flow Infographic

libterm.com

libterm.com