Radiographic testing is a powerful non-destructive inspection method that uses X-rays or gamma rays to detect internal flaws in materials and components without causing damage. This technique is essential for ensuring the structural integrity and safety of critical parts in industries like aerospace, construction, and manufacturing. Explore the rest of the article to understand how radiographic testing can enhance your quality control processes.

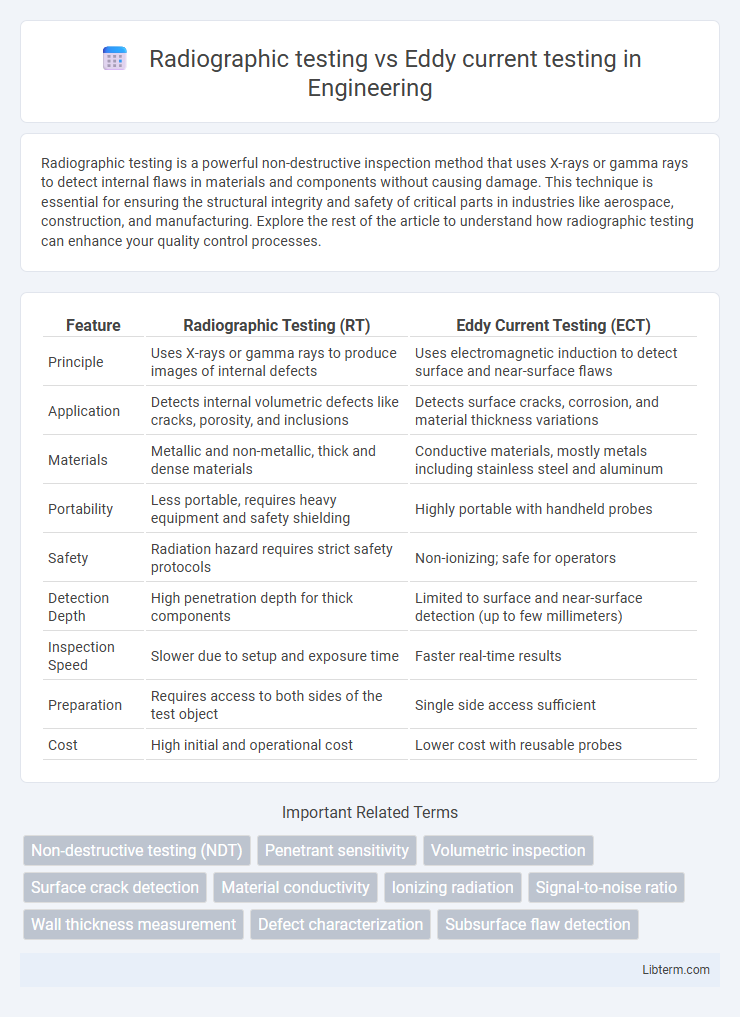

Table of Comparison

| Feature | Radiographic Testing (RT) | Eddy Current Testing (ECT) |

|---|---|---|

| Principle | Uses X-rays or gamma rays to produce images of internal defects | Uses electromagnetic induction to detect surface and near-surface flaws |

| Application | Detects internal volumetric defects like cracks, porosity, and inclusions | Detects surface cracks, corrosion, and material thickness variations |

| Materials | Metallic and non-metallic, thick and dense materials | Conductive materials, mostly metals including stainless steel and aluminum |

| Portability | Less portable, requires heavy equipment and safety shielding | Highly portable with handheld probes |

| Safety | Radiation hazard requires strict safety protocols | Non-ionizing; safe for operators |

| Detection Depth | High penetration depth for thick components | Limited to surface and near-surface detection (up to few millimeters) |

| Inspection Speed | Slower due to setup and exposure time | Faster real-time results |

| Preparation | Requires access to both sides of the test object | Single side access sufficient |

| Cost | High initial and operational cost | Lower cost with reusable probes |

Introduction to Non-Destructive Testing Methods

Radiographic testing (RT) uses X-rays or gamma rays to create images of internal defects in materials, providing detailed visualization of flaws such as cracks or voids within welds and castings. Eddy current testing (ECT) employs electromagnetic induction to detect surface and near-surface defects in conductive materials, making it highly effective for inspecting thin metal components and detecting corrosion or cracks. Both methods serve crucial roles in non-destructive testing (NDT) by enabling defect detection without damaging the test object, with RT excelling in volumetric inspections and ECT offering rapid, surface-sensitive evaluations.

Overview of Radiographic Testing

Radiographic testing (RT) utilizes X-rays or gamma rays to produce images of an object's internal structure, enabling the detection of defects such as cracks, voids, and inclusions. This non-destructive testing method is highly effective for inspecting welds, castings, and composite materials in industries like aerospace, construction, and manufacturing. Radiographic testing provides detailed visualization that assists in quality control and safety assurance by revealing internal flaws that may compromise structural integrity.

Overview of Eddy Current Testing

Eddy Current Testing (ECT) utilizes electromagnetic induction to detect surface and near-surface flaws in conductive materials, offering rapid and non-destructive evaluation without requiring direct contact or coupling mediums. ECT excels in identifying cracks, corrosion, and material thickness variations, particularly in complex geometries or layered structures, where traditional Radiographic Testing (RT) may face limitations due to radiation safety concerns and longer processing times. Its sensitivity to material conductivity and permeability changes makes ECT an efficient method for preventive maintenance and quality control in aerospace, automotive, and power generation industries.

Principles Behind Radiographic Testing

Radiographic testing relies on the principle of using X-rays or gamma rays to produce images of the internal structure of a material, revealing defects based on varying absorption rates. The technique captures differences in material density and thickness, which appear as contrasts on the radiographic film or digital detector. This method provides detailed visualization of internal flaws such as cracks, voids, and inclusions, making it essential for non-destructive testing in industries like aerospace and construction.

Principles Behind Eddy Current Testing

Eddy current testing operates on the principle of electromagnetic induction, where an alternating current flows through a coil to generate a changing magnetic field that induces eddy currents in the conductive test material. These eddy currents create their own magnetic fields, which interact with the original field, causing measurable changes in coil impedance that reveal material defects or variations. Unlike radiographic testing, which relies on ionizing radiation to produce shadow images of internal structures, eddy current testing offers immediate feedback and is highly sensitive to surface and near-surface flaws in conductive materials.

Advantages of Radiographic Testing

Radiographic testing provides detailed imaging of internal defects with high resolution, enabling precise identification and characterization of flaws such as cracks, voids, and inclusions. It is highly effective for inspecting complex geometries and thick materials where other methods like eddy current testing may be limited. Radiographic testing also offers a permanent record of the inspection, facilitating traceability and future reference.

Advantages of Eddy Current Testing

Eddy Current Testing offers distinct advantages over Radiographic Testing, including faster inspection times and improved safety since it does not involve ionizing radiation exposure. The method allows for precise detection of surface and near-surface defects in conductive materials, providing high sensitivity to cracks, corrosion, and material thickness variations. Its portability and ease of automation further enhance efficiency in field inspections and quality control processes.

Limitations and Challenges of Each Method

Radiographic testing (RT) faces limitations such as exposure to harmful radiation, lengthy processing times, and difficulty detecting flaws in complex geometries or thick materials. Eddy current testing (ECT) encounters challenges with limited penetration depth in conductive materials, sensitivity to surface conditions, and difficulty inspecting non-metallic or coated components. Both methods require skilled operators and may struggle with accurate defect characterization in intricate or heterogeneous test environments.

Ideal Applications: When to Use Radiographic or Eddy Current Testing

Radiographic testing is ideal for inspecting welds, castings, and complex metal structures where internal defects such as cracks, porosity, or inclusions need precise imaging. Eddy current testing excels in assessing surface and near-surface flaws in conductive materials, particularly useful for detecting corrosion, cracks, and material thinning in tubing, aircraft components, and pipelines. Selecting Radiographic testing is preferred when detailed defect visualization inside thick or multilayered parts is required, whereas Eddy current testing suits high-speed inspections and materials with varied conductivity or magnetic properties.

Summary and Selection Criteria

Radiographic testing (RT) provides detailed imaging of internal flaws using X-rays or gamma rays, ideal for detecting volumetric defects in welds and castings, while Eddy current testing (ECT) uses electromagnetic fields to identify surface and near-surface defects, especially in conductive materials. Selection criteria depend on factors such as material type, defect location, test accessibility, and the required sensitivity; RT is preferred for thick sections and complex geometries, whereas ECT is favored for surface crack detection and rapid inspections on conductive metals. Cost, safety considerations, and inspection speed also influence the choice, with ECT offering faster, safer assessments and RT delivering comprehensive structural evaluations.

Radiographic testing Infographic

libterm.com

libterm.com