Compressive strength measures the ability of a material to withstand axial loads that reduce its size, crucial for construction and engineering projects. Understanding this property ensures the durability and safety of structures under various stress conditions. Explore the article to learn how compressive strength impacts your material choices and project outcomes.

Table of Comparison

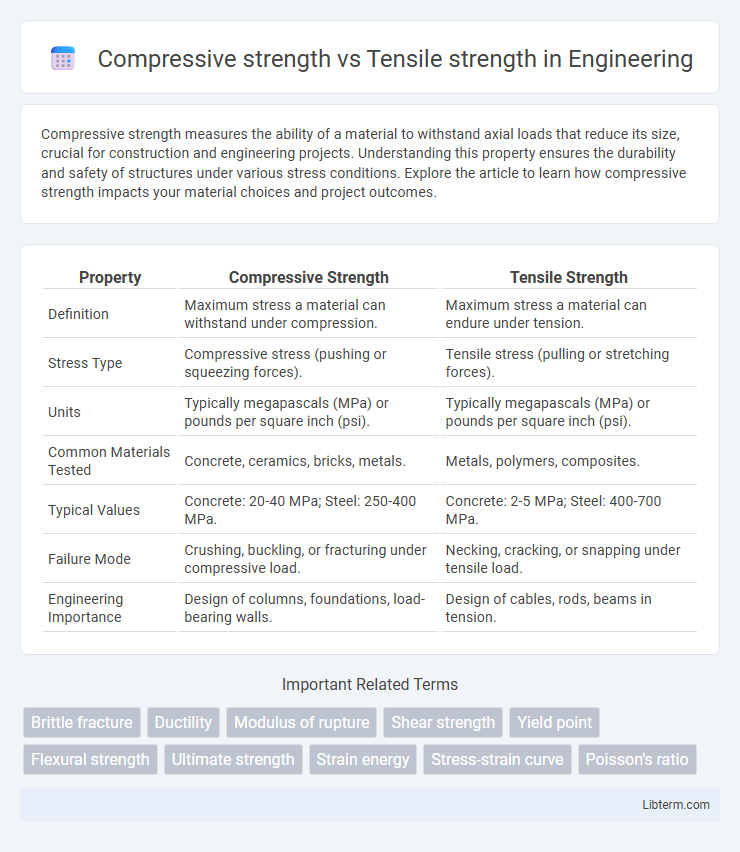

| Property | Compressive Strength | Tensile Strength |

|---|---|---|

| Definition | Maximum stress a material can withstand under compression. | Maximum stress a material can endure under tension. |

| Stress Type | Compressive stress (pushing or squeezing forces). | Tensile stress (pulling or stretching forces). |

| Units | Typically megapascals (MPa) or pounds per square inch (psi). | Typically megapascals (MPa) or pounds per square inch (psi). |

| Common Materials Tested | Concrete, ceramics, bricks, metals. | Metals, polymers, composites. |

| Typical Values | Concrete: 20-40 MPa; Steel: 250-400 MPa. | Concrete: 2-5 MPa; Steel: 400-700 MPa. |

| Failure Mode | Crushing, buckling, or fracturing under compressive load. | Necking, cracking, or snapping under tensile load. |

| Engineering Importance | Design of columns, foundations, load-bearing walls. | Design of cables, rods, beams in tension. |

Introduction to Compressive and Tensile Strength

Compressive strength measures a material's ability to withstand loads that reduce its size by applying pressure, crucial for structural components like concrete and metals. Tensile strength assesses a material's resistance to breaking under tension or pulling forces, essential in applications involving cables, wires, and reinforced materials. Understanding both properties is vital for selecting appropriate materials in engineering and construction to ensure safety and durability.

Defining Compressive Strength

Compressive strength refers to the maximum load a material can withstand when subjected to crushing or compressive forces before failing or deforming. It is a critical property for materials used in construction and engineering applications, such as concrete, metals, and ceramics, where resistance to compression is essential. Unlike tensile strength, which measures resistance to pulling forces, compressive strength determines how well a material resists being compacted or shortened under pressure.

Understanding Tensile Strength

Tensile strength measures a material's ability to withstand pulling forces without breaking, crucial for applications involving stretching or bending. It quantifies the maximum stress a material can endure while being stretched before failure, often tested using a tensile test machine. Understanding tensile strength helps engineers select appropriate materials for structural components that must resist tension, such as cables, beams, and fasteners.

Key Differences Between Compressive and Tensile Strength

Compressive strength measures a material's ability to withstand loads that reduce its size by pushing or squeezing, while tensile strength evaluates resistance to forces that attempt to pull or stretch the material apart. Concrete typically exhibits high compressive strength but relatively low tensile strength, necessitating reinforcement with steel bars to improve tensile performance. The key difference lies in the nature of applied forces and failure modes: compressive strength resists crushing, whereas tensile strength resists elongation and breaking.

Importance in Material Selection

Compressive strength and tensile strength are critical mechanical properties influencing material selection in engineering and construction. Compressive strength measures a material's ability to withstand axial loads that reduce size, essential for components subjected to crushing forces like concrete in foundations. Tensile strength indicates how well a material resists elongation or breaking under tension, crucial for applications involving stretching or pulling such as steel cables and reinforced fibers.

Factors Affecting Compressive and Tensile Strength

Compressive strength depends largely on material density, porosity, and moisture content, with higher density and lower porosity typically enhancing resistance to crushing forces. Tensile strength is influenced by factors such as microstructure, fiber orientation in composites, and presence of voids or cracks, which can initiate failure under pulling forces. Both strengths are affected by temperature and loading rate, where elevated temperatures and rapid loading often reduce material performance.

Testing Methods for Strength Measurement

Compressive strength is measured using a Universal Testing Machine (UTM) where a specimen, typically concrete or metal, is subjected to increasing axial load until failure occurs. Tensile strength testing involves applying a uniaxial tensile load on a specimen, often metal or polymer, using a UTM equipped with tensile grips and extensometers to record elongation and ultimate load at fracture. Both testing methods adhere to standards such as ASTM C39 for compressive strength and ASTM E8 for tensile strength, ensuring consistent and accurate strength measurement across materials.

Real-world Applications and Examples

Compressive strength is crucial in construction materials like concrete and stone, which must withstand heavy loads in buildings, bridges, and dams without crushing. Tensile strength is vital for materials such as steel cables, ropes, and reinforcement bars that endure pulling forces in suspension bridges, elevators, and tension structures. Understanding the balance between compressive and tensile strengths informs the design of composite materials, ensuring safety and durability in real-world engineering applications.

Advantages and Limitations of Each Strength Type

Compressive strength excels in resisting forces that push materials together, making it ideal for structural foundations and load-bearing applications, but it is limited in withstanding cracking or failure under tension. Tensile strength is crucial for materials subjected to pulling forces, enhancing durability in cables and beams, yet it often underperforms in scenarios involving crushing or compression. Balancing these strengths based on application requirements optimizes material selection and ensures structural integrity.

Conclusion: Choosing the Right Material Strength

Compressive strength measures a material's ability to withstand loads that reduce its size, while tensile strength evaluates its capacity to resist forces causing elongation or breaking. Selecting the right material strength depends on the specific application's load conditions, with structures like bridges favoring high tensile strength and foundations requiring superior compressive strength. Understanding the distinct roles of compressive and tensile strengths ensures optimal performance and safety in engineering designs.

Compressive strength Infographic

libterm.com

libterm.com