The proportional limit is the maximum stress a material can withstand while maintaining a linear relationship between stress and strain, ensuring elastic deformation. Beyond this point, permanent deformation occurs, compromising the material's ability to return to its original shape. Discover how understanding the proportional limit impacts your material selection and design decisions throughout this article.

Table of Comparison

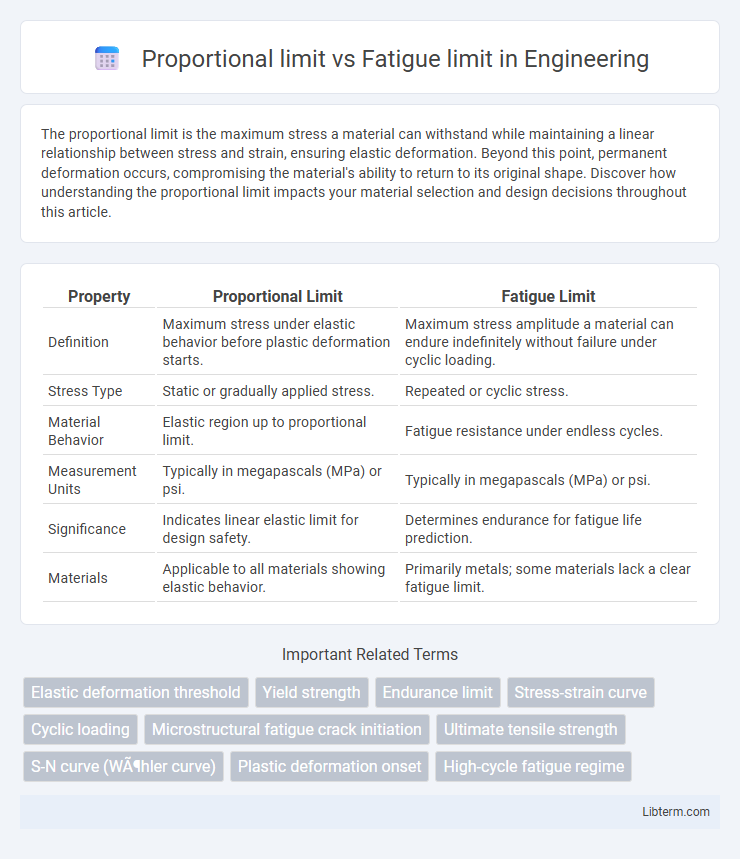

| Property | Proportional Limit | Fatigue Limit |

|---|---|---|

| Definition | Maximum stress under elastic behavior before plastic deformation starts. | Maximum stress amplitude a material can endure indefinitely without failure under cyclic loading. |

| Stress Type | Static or gradually applied stress. | Repeated or cyclic stress. |

| Material Behavior | Elastic region up to proportional limit. | Fatigue resistance under endless cycles. |

| Measurement Units | Typically in megapascals (MPa) or psi. | Typically in megapascals (MPa) or psi. |

| Significance | Indicates linear elastic limit for design safety. | Determines endurance for fatigue life prediction. |

| Materials | Applicable to all materials showing elastic behavior. | Primarily metals; some materials lack a clear fatigue limit. |

Introduction to Proportional Limit and Fatigue Limit

The proportional limit marks the maximum stress a material can withstand while deforming elastically, where stress and strain maintain a linear relationship according to Hooke's law. The fatigue limit, or endurance limit, represents the stress threshold below which a material can endure an infinite number of load cycles without failure, critical for predicting the durability of metals under cyclic loading. Understanding the proportional limit and fatigue limit is essential for designing components that resist both immediate deformation and long-term cyclic stresses.

Defining Proportional Limit

Proportional limit is the maximum stress at which a material's stress-strain curve remains linear, indicating elastic behavior where deformation is directly proportional to the applied load. Fatigue limit, in contrast, refers to the highest stress level a material can withstand for an infinite number of cycles without failure. Understanding the proportional limit is essential for predicting material performance under elastic loading conditions before permanent deformation or fatigue damage occurs.

Understanding Fatigue Limit

The fatigue limit, also known as the endurance limit, defines the maximum stress a material can endure indefinitely without failing due to fatigue, whereas the proportional limit marks the highest stress at which a material deforms elastically. Understanding the fatigue limit is crucial for designing components subject to cyclic loading, as it predicts the stress threshold below which the material's life is theoretically infinite. Materials like steels typically exhibit a well-defined fatigue limit, enabling engineers to ensure structural integrity under repetitive stress conditions.

Key Differences Between Proportional Limit and Fatigue Limit

The proportional limit defines the maximum stress a material can withstand while maintaining a linear stress-strain relationship, marking the end of elastic behavior, whereas the fatigue limit represents the stress level below which a material can endure infinite cyclic loading without failure. Proportional limit is a static property measured under monotonic loading conditions, while fatigue limit pertains to dynamic loading and the material's endurance over repeated stress cycles. Understanding these distinctions is critical for designing components subjected to both immediate and repeated mechanical forces.

Importance in Material Selection

The proportional limit defines the maximum stress a material can withstand without permanent deformation, critical for ensuring structural integrity in load-bearing applications. The fatigue limit indicates the stress threshold below which a material can endure infinite load cycles without failure, essential for components subjected to repetitive stress. Prioritizing both limits in material selection enhances durability and reliability, preventing unexpected failures in mechanical and structural engineering designs.

Factors Affecting Proportional Limit

The proportional limit of a material is influenced by factors such as temperature, strain rate, material composition, and microstructural defects, which affect its elastic behavior before plastic deformation begins. Higher temperatures and strain rates generally reduce the proportional limit by accelerating atomic movement and dislocation activities. Unlike the fatigue limit, which depends on cyclic loading and surface conditions, the proportional limit primarily reflects the intrinsic elastic properties determined by the material's microstructure and chemical makeup.

Factors Influencing Fatigue Limit

The fatigue limit, unlike the proportional limit, is significantly influenced by factors such as material microstructure, surface finish, temperature, and cyclic loading frequency. Grain size and impurities within a metal can accelerate crack initiation, reducing fatigue strength, while surface roughness increases stress concentration points leading to earlier failure. Environmental conditions such as corrosion and temperature fluctuations also degrade fatigue performance by promoting crack propagation beyond the material's fatigue limit.

Testing Methods for Proportional Limit and Fatigue Limit

Proportional limit testing involves tensile or compression tests using strain gauges to measure the point at which stress and strain cease to be linear, often conducted with universal testing machines under controlled loading rates. Fatigue limit testing employs cyclic loading using rotating bending, axial, or flexural fatigue testers to determine the maximum stress amplitude a material can endure for an infinite number of cycles without failure, with data collected through S-N curves analysis. Strain-controlled or load-controlled fatigue testing protocols are applied depending on material behavior, utilizing devices like servo-hydraulic fatigue testing machines to monitor crack initiation and propagation.

Practical Applications in Engineering

The proportional limit defines the maximum stress a material can withstand while maintaining a linear elastic relationship, crucial for designing structures that must avoid permanent deformation. Fatigue limit represents the stress threshold below which a material can endure infinite load cycles without failure, essential for components subjected to repetitive loading like bridges and aircraft wings. Engineers use the proportional limit for static load calculations, whereas the fatigue limit informs the life expectancy and safety of dynamic or cyclically stressed parts.

Summary and Implications for Material Design

The proportional limit marks the maximum stress a material can withstand while maintaining elastic behavior, crucial for ensuring structural integrity under initial loads. The fatigue limit defines the stress threshold below which a material can endure infinite cyclic loading without failure, essential for designing components subjected to repetitive stress. Understanding both limits enables engineers to optimize material selection and design for durability and safety in applications ranging from aerospace to civil engineering.

Proportional limit Infographic

libterm.com

libterm.com