Profile tolerance controls the allowable variation in the surface contour of a part, ensuring it meets precise design specifications. This type of geometric tolerance is crucial for maintaining functionality and interchangeability in mechanical components. Discover how understanding profile tolerance enhances your manufacturing accuracy by exploring the rest of this article.

Table of Comparison

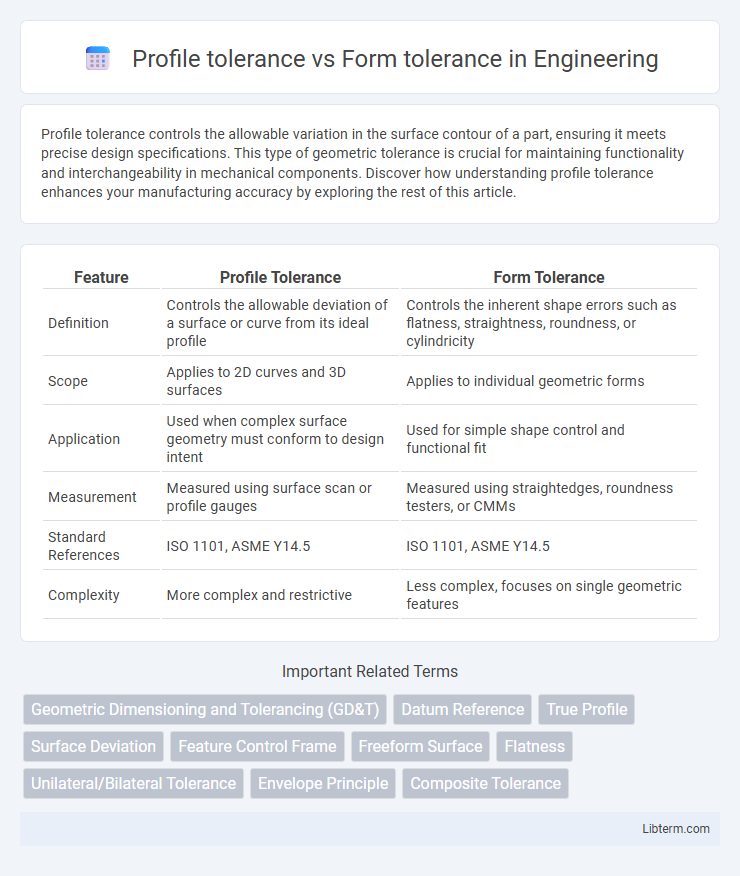

| Feature | Profile Tolerance | Form Tolerance |

|---|---|---|

| Definition | Controls the allowable deviation of a surface or curve from its ideal profile | Controls the inherent shape errors such as flatness, straightness, roundness, or cylindricity |

| Scope | Applies to 2D curves and 3D surfaces | Applies to individual geometric forms |

| Application | Used when complex surface geometry must conform to design intent | Used for simple shape control and functional fit |

| Measurement | Measured using surface scan or profile gauges | Measured using straightedges, roundness testers, or CMMs |

| Standard References | ISO 1101, ASME Y14.5 | ISO 1101, ASME Y14.5 |

| Complexity | More complex and restrictive | Less complex, focuses on single geometric features |

Understanding Profile Tolerance: Definition and Purpose

Profile tolerance defines a three-dimensional boundary around a surface that controls the allowable deviation of the entire surface from its ideal shape, ensuring precise contour and form consistency. It governs the entire surface geometry, providing comprehensive control over complex shapes and contours in manufacturing and inspection. This tolerance is essential for maintaining the functional fit and aesthetic quality of parts with intricate designs, differentiating it from form tolerance which typically applies to individual geometric elements like straightness or flatness.

What is Form Tolerance? Key Concepts Explained

Form tolerance specifies the allowable deviation in the shape of a single feature from its perfect geometric form, controlling aspects like flatness, straightness, roundness, and cylindricity. This tolerance ensures that individual features maintain their ideal shape without reference to other features or true positions, making it essential for controlling manufacturing precision on a micro-level. Key concepts include the tolerance zone, which defines the permissible variation boundary, and the localized control of element geometry rather than overall part layout.

Profile Tolerance vs Form Tolerance: Core Differences

Profile tolerance controls the entire surface shape by establishing a boundary zone within which the surface must lie, enabling precise control over complex contours and freeform surfaces. Form tolerance restricts specific geometric elements such as flatness, straightness, roundness, or cylindricity to ensure individual feature shapes meet design requirements. The core difference lies in profile tolerance's ability to govern entire surface geometry, while form tolerance focuses on limiting deviations in isolated geometric features.

Types of Profile Tolerances in Engineering

Profile tolerance in engineering defines a three-dimensional boundary around a surface or feature, controlling its shape and location within specified limits. There are several types of profile tolerances, including Profile of a Line, Profile of a Surface, and Composite Profile, each ensuring precise control over linear or surface deviations in parts. Form tolerance, in contrast, strictly limits geometric imperfections like flatness or straightness without considering location or orientation.

Common Types of Form Tolerances and Their Applications

Profile tolerance controls the shape of surfaces by defining a three-dimensional boundary zone around a CAD-defined profile, allowing precise control over complex contours in aerospace and automotive parts. Common types of form tolerances include flatness, cylindricity, and straightness, each regulating a specific geometric characteristic to ensure the part's functionality and assembly quality. Flatness ensures surfaces are within a specified tolerance zone, cylindricity controls the uniformity of cylindrical parts, and straightness manages the deviation along a line, critical in manufacturing shafts, engine components, and precision molds.

Interpretation of Profile and Form Tolerances on Drawings

Profile tolerances control the entire surface or a specific line on a part, ensuring it remains within a uniform boundary zone defined by the tolerance values, which helps in maintaining the shape and consistency of complex curves or surfaces. Form tolerances, including flatness, straightness, circularity, and cylindricity, focus on individual geometric features, controlling deviations from the ideal form without referencing other features or datums. Interpretation on drawings requires identifying profile tolerances by their characteristic symbols and tolerance zones around surfaces or lines, while form tolerances are applied to single features, ensuring dimensional precision and functional fit in manufacturing and inspection processes.

When to Use Profile Tolerance vs Form Tolerance

Profile tolerance is used when controlling complex surfaces or multiple features simultaneously, ensuring the entire contour conforms within specified limits. Form tolerance applies to single geometric features like straightness, flatness, circularity, or cylindricity, focusing on the shape of individual elements without reference to other features. Use profile tolerance for controlling 3D surface geometry in assemblies or molded parts, and form tolerance for simpler, isolated feature shape control in machining or inspection.

Advantages and Limitations of Profile Tolerancing

Profile tolerance controls the surface contour of a feature, allowing precise specification of complex shapes and ensuring uniformity in manufacturing processes. It offers the advantage of tightly controlling both size and form, which improves part functionality and assembly fit, but its complexity can lead to higher inspection costs and require advanced measurement techniques. Limitations include difficulty in interpretation for simple geometries and potential over-restriction that may increase production time and costs.

Practical Applications: Industry Examples and Case Studies

Profile tolerance controls the allowable deviation of a surface contour within a specified boundary, essential in automotive and aerospace industries for aerodynamic component precision. Form tolerance, including flatness and straightness, ensures individual element shapes meet strict geometric criteria, widely used in manufacturing precision machined parts and assembly processes. Case studies in electronics manufacturing demonstrate how profile tolerance improves circuit board fitting accuracy, while form tolerance guarantees component base flatness for optimal device function.

Best Practices for Specifying Profile and Form Tolerances

Profile tolerance controls the allowable variation of a surface relative to a true geometric shape, ensuring precise contour and location on complex features. Form tolerance limits specific geometric deviations such as flatness, straightness, circularity, and cylindricity, maintaining the integrity of individual features without relation to datum references. Best practices include clearly defining datum references for profile tolerances to control form and orientation collectively, and specifying form tolerances separately on features requiring strict shape control independent of positional requirements.

Profile tolerance Infographic

libterm.com

libterm.com