Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems are essential for automating industrial processes, enabling precise control and real-time data monitoring. PLCs execute control instructions directly on machinery, while SCADA provides a comprehensive interface for monitoring, data collection, and remote control across complex operations. Discover how mastering PLC and SCADA technologies can enhance your operational efficiency and reliability by exploring the full article.

Table of Comparison

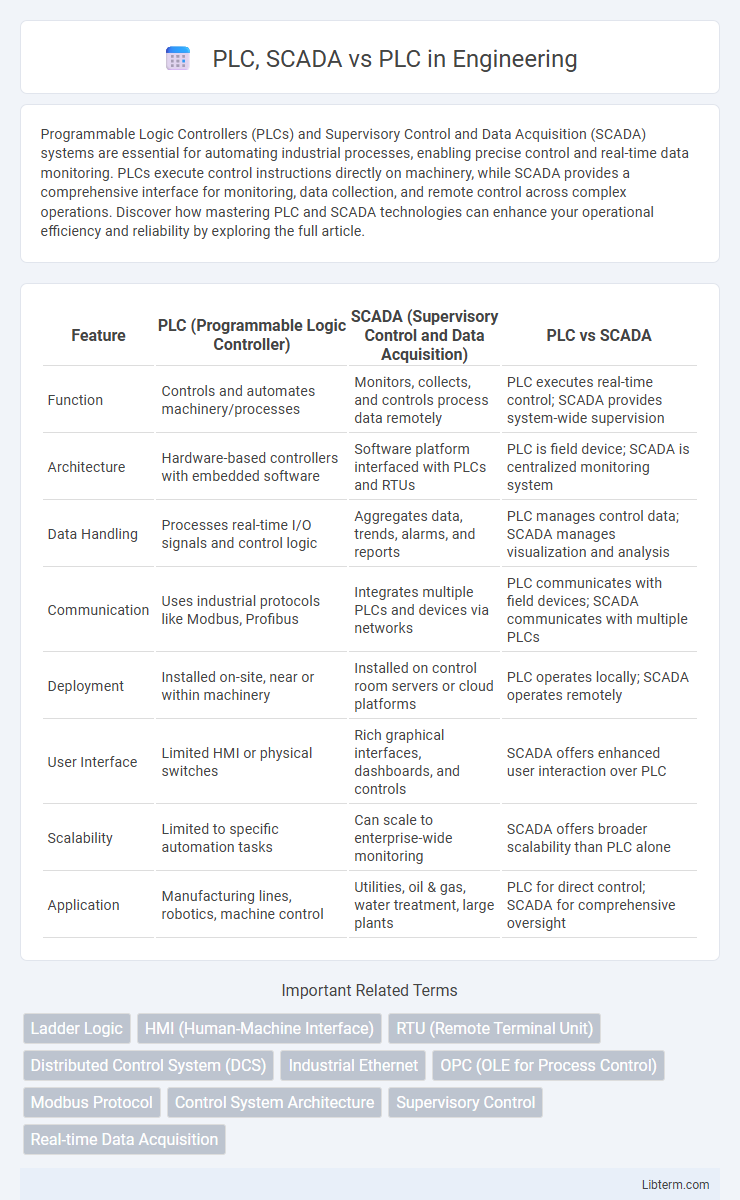

| Feature | PLC (Programmable Logic Controller) | SCADA (Supervisory Control and Data Acquisition) | PLC vs SCADA |

|---|---|---|---|

| Function | Controls and automates machinery/processes | Monitors, collects, and controls process data remotely | PLC executes real-time control; SCADA provides system-wide supervision |

| Architecture | Hardware-based controllers with embedded software | Software platform interfaced with PLCs and RTUs | PLC is field device; SCADA is centralized monitoring system |

| Data Handling | Processes real-time I/O signals and control logic | Aggregates data, trends, alarms, and reports | PLC manages control data; SCADA manages visualization and analysis |

| Communication | Uses industrial protocols like Modbus, Profibus | Integrates multiple PLCs and devices via networks | PLC communicates with field devices; SCADA communicates with multiple PLCs |

| Deployment | Installed on-site, near or within machinery | Installed on control room servers or cloud platforms | PLC operates locally; SCADA operates remotely |

| User Interface | Limited HMI or physical switches | Rich graphical interfaces, dashboards, and controls | SCADA offers enhanced user interaction over PLC |

| Scalability | Limited to specific automation tasks | Can scale to enterprise-wide monitoring | SCADA offers broader scalability than PLC alone |

| Application | Manufacturing lines, robotics, machine control | Utilities, oil & gas, water treatment, large plants | PLC for direct control; SCADA for comprehensive oversight |

Introduction to PLC Systems

Programmable Logic Controllers (PLCs) are specialized industrial computers designed to automate manufacturing processes by monitoring inputs and controlling outputs in real-time. PLC systems offer high reliability, robustness, and ease of programming with ladder logic or function block diagrams, making them essential in industrial automation for tasks such as motor control, assembly lines, and robotic devices. Unlike SCADA systems that provide supervisory control and data acquisition across wide networks, PLCs focus on direct, fast control of machinery and equipment at the process level.

Key Components of PLC Architecture

PLC architecture consists of key components such as the central processing unit (CPU), input/output (I/O) modules, power supply, and communication interfaces that enable real-time control and automation. SCADA systems, in contrast, integrate PLCs with supervisory control and data acquisition software for centralized monitoring and data analysis across multiple devices and locations. Understanding PLC architecture is crucial for optimizing industrial automation, as it directly impacts system reliability, response time, and scalability in both standalone and SCADA-integrated environments.

Understanding SCADA: An Overview

SCADA (Supervisory Control and Data Acquisition) systems provide centralized monitoring and control of industrial processes, offering real-time data acquisition, visualization, and automation across multiple PLCs (Programmable Logic Controllers). Unlike standalone PLCs that control specific equipment or machinery, SCADA integrates data from various PLCs to facilitate comprehensive system management and decision-making. Understanding SCADA's architecture, including its components like HMIs (Human-Machine Interfaces) and communication networks, is essential for optimizing industrial automation and improving operational efficiency.

PLC vs SCADA: Core Differences

PLC (Programmable Logic Controller) is a hardware device designed for real-time control of industrial processes, executing predefined logic to automate machinery and equipment. SCADA (Supervisory Control and Data Acquisition) is a software system that monitors, gathers, and analyzes data from multiple PLCs and other devices to provide centralized control and visualization. The core difference lies in PLCs performing direct process automation and control, while SCADA offers supervisory-level data management, system monitoring, and operator interface functions.

Common Applications of PLCs

PLCs (Programmable Logic Controllers) are widely used in industrial automation for monitoring and controlling machinery processes, such as assembly lines, robotic devices, and manufacturing equipment. SCADA (Supervisory Control and Data Acquisition) systems complement PLCs by offering centralized data collection, real-time monitoring, and control across large-scale operations like power plants, water treatment facilities, and oil pipelines. Common applications of PLCs include automated conveyor systems, packaging machines, and HVAC control, where precise, reliable, and fast response is critical for operational efficiency.

Typical Uses of SCADA in Industry

SCADA systems are primarily used in industries such as oil and gas, water treatment, power generation, and manufacturing to monitor and control large-scale processes across multiple sites. Unlike PLCs that handle localized, real-time control tasks, SCADA integrates data acquisition, supervisory control, and remote monitoring for complex infrastructure management. SCADA's capability to provide centralized visualization, alarm management, and historical data analysis enhances operational efficiency and decision-making in industrial environments.

Advantages and Limitations of PLC

PLCs (Programmable Logic Controllers) excel in robust, real-time control of industrial machinery with high reliability and resistance to harsh environments, offering straightforward programming and fast execution. SCADA (Supervisory Control and Data Acquisition) systems provide extensive monitoring, data collection, and remote control functionalities, enhancing visualization and centralized management but relying on PLCs for direct process control. Limitations of PLCs include constrained data processing capacity and limited ability for comprehensive system-wide visualization compared to SCADA, making PLCs ideal for localized control and SCADA essential for supervisory control and data analytics.

Benefits and Drawbacks of SCADA

SCADA systems enhance industrial automation by providing real-time monitoring, data acquisition, and centralized control, which improves operational efficiency and reduces downtime compared to standalone PLCs. However, SCADA requires complex installation, higher initial costs, and ongoing maintenance, making it less suitable for small-scale operations with limited budgets. Despite these drawbacks, SCADA's ability to integrate multiple PLCs and offer detailed analytics delivers significant benefits in large, distributed, or critical infrastructure environments.

Integration Between PLC and SCADA

PLC systems execute real-time control by processing input signals and managing outputs in industrial automation, while SCADA software monitors and visualizes these processes remotely. Integration between PLC and SCADA enables seamless data exchange via communication protocols such as Modbus, OPC UA, or Ethernet/IP, enhancing system efficiency and operational visibility. This synchronized interaction allows for real-time data acquisition, remote control, and predictive maintenance, optimizing overall industrial performance.

Choosing the Right Solution: PLC, SCADA, or Both?

Selecting the right automation solution depends on the specific needs of the industrial process, where PLC (Programmable Logic Controller) excels in real-time control and machinery automation, while SCADA (Supervisory Control and Data Acquisition) specializes in monitoring, data collection, and supervisory control over large, complex systems. Integrating both PLC and SCADA offers comprehensive control and visibility, enabling precise operation management and efficient data-driven decisions. Evaluating factors like process complexity, scalability, and data requirements ensures optimal use of PLC and SCADA technologies for enhanced operational performance.

PLC, SCADA Infographic

libterm.com

libterm.com