Direct energy conversion efficiently transforms one energy form directly into another without mechanical intermediaries, enhancing overall efficiency and reducing energy losses. Examples include thermoelectric generators that convert heat to electricity and photovoltaic cells converting sunlight to electrical power. Explore how direct energy conversion technologies can optimize your energy solutions in the full article.

Table of Comparison

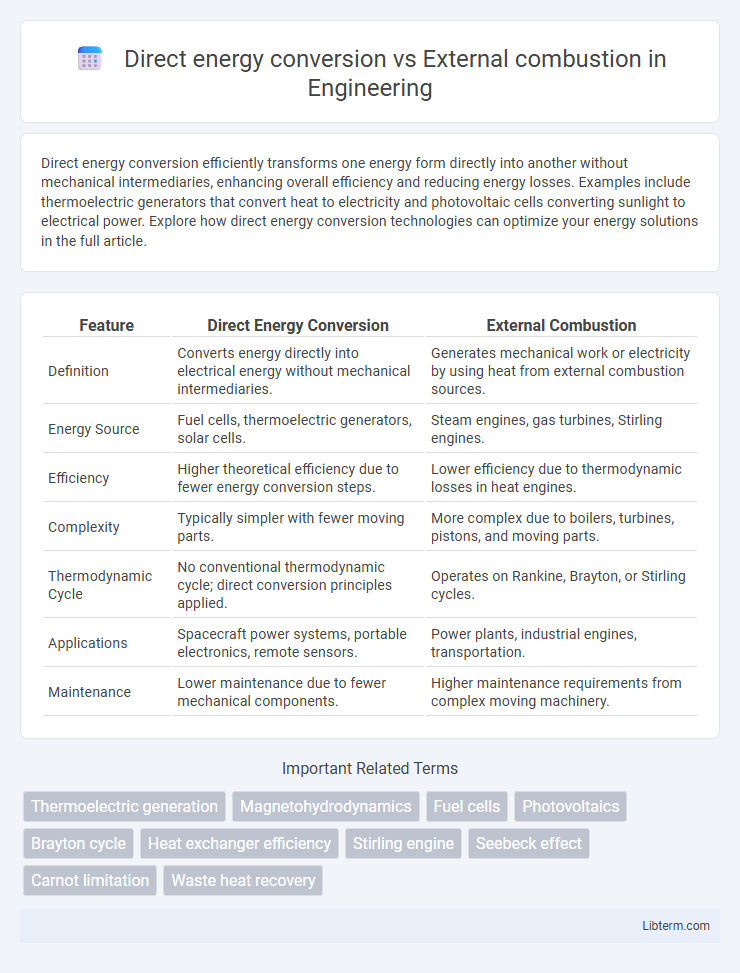

| Feature | Direct Energy Conversion | External Combustion |

|---|---|---|

| Definition | Converts energy directly into electrical energy without mechanical intermediaries. | Generates mechanical work or electricity by using heat from external combustion sources. |

| Energy Source | Fuel cells, thermoelectric generators, solar cells. | Steam engines, gas turbines, Stirling engines. |

| Efficiency | Higher theoretical efficiency due to fewer energy conversion steps. | Lower efficiency due to thermodynamic losses in heat engines. |

| Complexity | Typically simpler with fewer moving parts. | More complex due to boilers, turbines, pistons, and moving parts. |

| Thermodynamic Cycle | No conventional thermodynamic cycle; direct conversion principles applied. | Operates on Rankine, Brayton, or Stirling cycles. |

| Applications | Spacecraft power systems, portable electronics, remote sensors. | Power plants, industrial engines, transportation. |

| Maintenance | Lower maintenance due to fewer mechanical components. | Higher maintenance requirements from complex moving machinery. |

Introduction to Energy Conversion Methods

Direct energy conversion transforms thermal energy to electrical energy using devices like thermoelectric generators and fuel cells, offering higher efficiency and reduced mechanical complexity. External combustion systems, such as steam turbines in power plants, rely on heat produced outside the working fluid, which drives mechanical components to generate electricity but usually experience thermal losses due to multiple energy transformation stages. Understanding the distinct mechanisms and efficiency implications of direct versus external combustion conversion methods is critical for optimizing energy systems in industrial and sustainable applications.

Overview of Direct Energy Conversion

Direct energy conversion involves transforming fuel energy directly into electrical power without intermediate mechanical processes, enhancing efficiency and reducing energy loss. Common technologies include thermoelectric generators, fuel cells, and magnetohydrodynamic systems, which leverage physical phenomena like thermoelectric effects, electrochemical reactions, or plasma flows. This contrasts with external combustion engines where fuel combustion generates mechanical motion to drive electricity production, typically resulting in lower conversion efficiency.

Fundamentals of External Combustion Systems

External combustion systems operate by transferring heat produced from burning fuel outside the working fluid, typically involving steam turbines or Stirling engines, which allows for diverse fuel usage and easier emission control. Direct energy conversion, such as in fuel cells or thermoelectric devices, converts chemical or thermal energy directly into electrical energy, bypassing mechanical intermediaries. The fundamentals of external combustion emphasize heat transfer efficiency, working fluid properties, and system design to optimize thermal-to-mechanical energy conversion.

Efficiency Comparison: Direct vs External Combustion

Direct energy conversion systems, such as fuel cells and thermoelectric generators, typically achieve higher efficiencies by converting fuel directly into electricity with minimal intermediate steps. External combustion engines, like steam turbines, often experience lower efficiency due to energy losses in heat transfer and mechanical conversion processes. Overall, direct energy conversion methods can reach efficiencies exceeding 60%, while external combustion systems generally operate below 40% efficiency under typical conditions.

Key Technologies in Direct Energy Conversion

Key technologies in direct energy conversion include thermoelectric generators, which convert temperature gradients directly into electrical voltage using the Seebeck effect, and fuel cells that transform chemical energy from fuels into electricity through electrochemical reactions without combustion. Thermionic converters exploit electron emission from heated materials to generate power, while magnetohydrodynamic (MHD) generators convert kinetic energy from ionized gases directly into electrical energy via electromagnetic fields. These technologies differ fundamentally from external combustion systems, which rely on mechanical work derived from heat engines driven by combustion products.

Applications of External Combustion Engines

External combustion engines find widespread application in power generation plants, particularly in steam turbines used for electricity production from coal, natural gas, and biomass. Industrial settings also utilize external combustion engines for mechanical drives and combined heat and power (CHP) systems, enhancing overall energy efficiency. Marine propulsion and locomotives benefit from the durability and fuel flexibility of external combustion engines, supporting large-scale transportation needs.

Environmental Impact Assessment

Direct energy conversion systems, such as fuel cells and thermoelectric generators, offer higher efficiency and lower greenhouse gas emissions by converting fuel directly into electrical energy with minimal heat loss. In contrast, external combustion engines, like steam turbines, rely on burning fuels to produce heat, resulting in significant carbon dioxide and pollutant emissions due to incomplete combustion and lower thermal efficiency. Environmental Impact Assessment highlights direct conversion technologies as preferable for reducing air pollution, mitigating climate change effects, and promoting sustainable energy solutions.

Cost and Maintenance Considerations

Direct energy conversion systems generally offer lower operational and maintenance costs due to fewer moving parts and simpler designs compared to external combustion systems. External combustion engines, such as steam turbines, require regular maintenance and fuel handling, which increases overall expenses and downtime. Investment in advanced direct conversion technologies can reduce lifecycle costs by improving efficiency and minimizing wear-related repairs.

Future Trends in Energy Conversion

Emerging trends in energy conversion emphasize the shift towards direct energy conversion technologies such as thermoelectric and fuel cells, which offer higher efficiency and lower emissions compared to traditional external combustion methods like coal and gas turbines. Innovations in materials science, such as advanced semiconductors and nanostructures, are enhancing the performance and scalability of direct conversion devices, enabling more sustainable and decentralized energy systems. Future energy infrastructures are expected to integrate hybrid systems combining direct conversion with external combustion for flexible, low-carbon power generation tailored to diverse applications.

Conclusion and Future Prospects

Direct energy conversion offers higher efficiency and reduced emissions compared to external combustion by minimizing mechanical losses and enabling compact system designs. Emerging technologies like thermoelectric materials and fuel cells promise further advancements in energy capture and integration within renewable systems. Continued research into material science and hybrid configurations will drive broader adoption and enhanced sustainability in future energy infrastructures.

Direct energy conversion Infographic

libterm.com

libterm.com