Brittle fracture occurs when a material breaks suddenly without significant plastic deformation, often resulting in rapid failure under stress. This type of fracture is characterized by a clean, flat fracture surface and typically happens at low temperatures or high strain rates. Discover how understanding brittle fracture can help you improve material safety and performance by reading the full article.

Table of Comparison

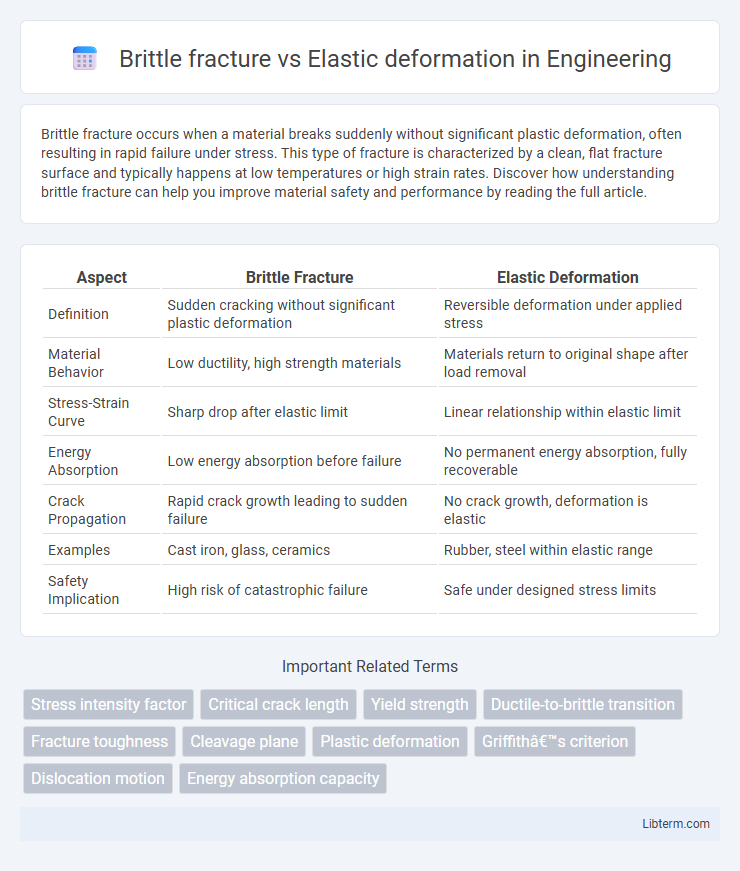

| Aspect | Brittle Fracture | Elastic Deformation |

|---|---|---|

| Definition | Sudden cracking without significant plastic deformation | Reversible deformation under applied stress |

| Material Behavior | Low ductility, high strength materials | Materials return to original shape after load removal |

| Stress-Strain Curve | Sharp drop after elastic limit | Linear relationship within elastic limit |

| Energy Absorption | Low energy absorption before failure | No permanent energy absorption, fully recoverable |

| Crack Propagation | Rapid crack growth leading to sudden failure | No crack growth, deformation is elastic |

| Examples | Cast iron, glass, ceramics | Rubber, steel within elastic range |

| Safety Implication | High risk of catastrophic failure | Safe under designed stress limits |

Introduction to Brittle Fracture and Elastic Deformation

Brittle fracture occurs when a material breaks suddenly without significant plastic deformation, typically along specific crystallographic planes, resulting in rapid crack propagation under stress. Elastic deformation refers to the reversible change in shape or size of a material under applied stress, where the material returns to its original form upon removal of the load. Understanding the distinction between brittle fracture and elastic deformation is critical in material science for predicting failure modes and designing components with appropriate mechanical properties.

Defining Brittle Fracture: Characteristics and Mechanisms

Brittle fracture occurs when a material breaks suddenly without significant plastic deformation, characterized by rapid crack propagation and minimal energy absorption. This phenomenon typically involves crack initiation at stress concentrators and fracture surfaces that appear granular or faceted under microscopy. Brittle fracture mechanisms often dominate in materials with low toughness at low temperatures or high strain rates, contrasting with elastic deformation where the material returns to its original shape after load removal.

Understanding Elastic Deformation: Fundamental Concepts

Elastic deformation occurs when a material returns to its original shape after the removal of an applied stress, governed by Hooke's Law within the elastic limit. Brittle fracture, in contrast, involves sudden crack propagation without significant plastic deformation, typically occurring once the material's tensile stress exceeds its fracture toughness. Understanding elastic deformation centers on stress-strain relationships, modulus of elasticity, and the reversible nature of atomic bond stretching within the material's microstructure.

Key Differences Between Brittle Fracture and Elastic Deformation

Brittle fracture occurs when a material breaks suddenly without significant plastic deformation, characterized by rapid crack propagation and low energy absorption. Elastic deformation refers to reversible changes in shape where the material returns to its original form after stress removal, involving stored elastic potential energy and no permanent damage. The key difference lies in brittle fracture causing immediate failure under stress, whereas elastic deformation is a temporary strain within the material's elastic limit.

Material Properties Influencing Failure Modes

Brittle fracture occurs when a material with low toughness and limited plastic deformation capacity fails suddenly under stress, often in materials like ceramics and high-strength steels. Elastic deformation is characterized by reversible strain, governed by the material's elastic modulus and yield strength, delaying permanent damage until the elastic limit is exceeded. Material properties such as fracture toughness, ductility, and strain rate sensitivity critically influence whether a material undergoes brittle fracture or elastic deformation during loading.

Stress-Strain Behavior: Brittle vs Elastic Response

Brittle fracture occurs with minimal plastic deformation, exhibiting a sudden drop in stress after reaching the elastic limit, characterized by a nearly linear stress-strain curve until failure. Elastic deformation shows a reversible linear stress-strain relationship where the material returns to its original shape after load removal, with no permanent strain. In brittle materials, stress concentration leads to crack initiation and rapid fracture, while elastic materials resist permanent damage under typical loading conditions.

Factors Affecting Brittle Fracture in Materials

Brittle fracture occurs when a material breaks without significant plastic deformation, contrasting with elastic deformation where the material returns to its original shape after stress removal. Factors affecting brittle fracture include low temperature, high strain rates, the presence of stress concentrators like cracks or notches, and material properties such as grain size and purity. Environmental conditions such as corrosion and hydrogen embrittlement also play a critical role in promoting brittle fracture over elastic deformation.

Real-World Applications and Failure Examples

Brittle fracture occurs suddenly without significant plastic deformation, making materials like ceramics and glass prone to catastrophic failure in structural applications such as aerospace and automotive components. Elastic deformation allows materials like steel and aluminum to return to their original shape under stress, essential in flexible mechanical parts and construction frameworks. Real-world failures from brittle fracture, like the Liberty ships cracking during WWII, contrast with elastic deformation cases where components endure repeated stress cycles without permanent damage.

Testing Methods for Brittle and Elastic Behavior

Testing methods for brittle fracture primarily include Charpy and Izod impact tests, which measure a material's ability to absorb energy and resist crack propagation under sudden stress. Elastic deformation is commonly evaluated using tensile tests and ultrasonic techniques, which assess a material's elastic modulus and ability to return to its original shape after load removal. Fracture toughness tests such as K_IC and CTOD specifically quantify a material's resistance to brittle crack initiation and growth under static or fatigue loading conditions.

Prevention and Mitigation Strategies for Brittle Fracture

Preventing brittle fracture involves maintaining materials above their ductile-to-brittle transition temperature and avoiding stress concentrations through proper design and material selection. Implementing heat treatments such as tempering can enhance toughness and reduce brittleness in metals like steel. Employing non-destructive testing methods like ultrasonic inspection allows early detection of micro-cracks, preventing catastrophic failure.

Brittle fracture Infographic

libterm.com

libterm.com