An elevator is a vital vertical transportation system designed to efficiently move people and goods between building floors. Modern elevators incorporate advanced safety features, energy-efficient technologies, and user-friendly controls to enhance the overall experience. Explore the rest of the article to discover how elevators work, their history, and the latest innovations shaping your daily commute.

Table of Comparison

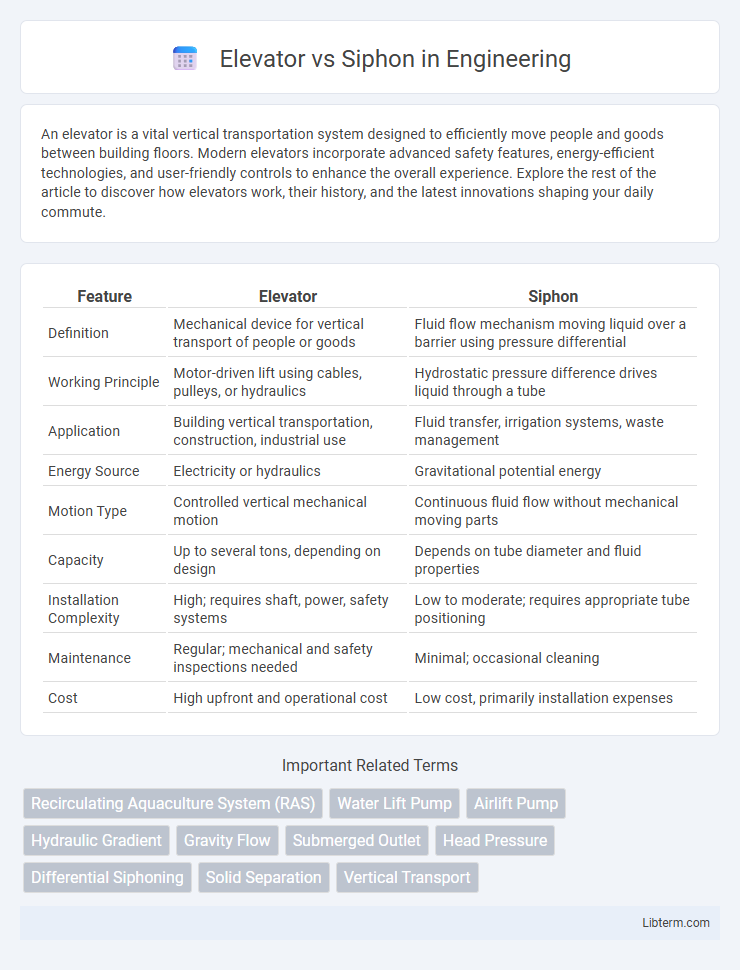

| Feature | Elevator | Siphon |

|---|---|---|

| Definition | Mechanical device for vertical transport of people or goods | Fluid flow mechanism moving liquid over a barrier using pressure differential |

| Working Principle | Motor-driven lift using cables, pulleys, or hydraulics | Hydrostatic pressure difference drives liquid through a tube |

| Application | Building vertical transportation, construction, industrial use | Fluid transfer, irrigation systems, waste management |

| Energy Source | Electricity or hydraulics | Gravitational potential energy |

| Motion Type | Controlled vertical mechanical motion | Continuous fluid flow without mechanical moving parts |

| Capacity | Up to several tons, depending on design | Depends on tube diameter and fluid properties |

| Installation Complexity | High; requires shaft, power, safety systems | Low to moderate; requires appropriate tube positioning |

| Maintenance | Regular; mechanical and safety inspections needed | Minimal; occasional cleaning |

| Cost | High upfront and operational cost | Low cost, primarily installation expenses |

Introduction to Elevators and Siphons

Elevators and siphons both transport fluids or materials but operate on fundamentally different principles. Elevators use mechanical devices such as motors and cables to lift objects vertically, commonly found in buildings for moving people or goods between floors. Siphons rely on atmospheric pressure and gravity to transfer liquids from a higher elevation to a lower one through a tube, requiring no external power source.

Principles of Operation: How Each System Works

An elevator operates by utilizing a motorized pulley system that moves a cabin vertically along a shaft, counterbalanced by weights to reduce energy consumption. A siphon functions based on gravity and atmospheric pressure, enabling liquid to flow from a higher elevation to a lower point through a tube, once the liquid column is established above the discharge level. While elevators use mechanical energy for vertical transport of people or goods, siphons rely on fluid dynamics principles to transfer liquids without mechanical assistance.

Key Applications: Where Elevators and Siphons Are Used

Elevators are primarily used in vertical transportation within buildings, facilitating efficient movement of people and goods in high-rise structures, warehouses, and industrial plants. Siphons are commonly applied in fluid transfer systems, agriculture irrigation, and wastewater management to move liquids across varying elevations without pumps. Both technologies optimize transport but address distinct vertical movement challenges in construction and fluid dynamics respectively.

Efficiency Comparison: Elevator vs Siphon

The efficiency of elevators typically ranges between 60% and 80%, influenced by factors such as motor type, load weight, and travel height, while siphons operate with near 100% efficiency by using gravity and atmospheric pressure to transfer liquids without mechanical energy. Elevators consume electrical power and incur losses due to friction and motor inefficiencies, making them less efficient for continuous fluid transport compared to siphons. In fluid transfer applications, siphons demonstrate superior energy efficiency, whereas elevators offer controlled vertical transport for solid or bulk materials despite higher energy consumption.

Installation and Maintenance Requirements

Elevators require complex installation involving shafts, motors, and control systems, demanding specialized technicians and significant structural modifications, while siphons offer simpler installation without electrical components, often relying on gravity and basic plumbing skills. Maintenance of elevators includes regular inspections, safety checks, lubrication of mechanical parts, and software updates to ensure smooth operation and compliance with safety regulations. Siphons, by contrast, need minimal maintenance, typically involving cleaning and occasional checking for leaks or blockages to maintain efficiency.

Cost Analysis: Upfront and Long-term Expenses

Elevators typically require higher upfront costs due to complex machinery, installation, and safety compliance expenses compared to siphons, which involve simpler design and installation. Long-term expenses for elevators include regular maintenance, energy consumption, and occasional repairs, whereas siphons generally incur minimal maintenance costs and no energy usage. Evaluating both options reveals that siphons are more cost-effective initially and maintain low operating expenses, while elevators demand significant investment but provide greater convenience and accessibility benefits.

Environmental Impact and Sustainability

Elevators consume significant amounts of electricity, contributing to greenhouse gas emissions unless powered by renewable energy sources, while siphons operate without external energy, promoting sustainable water transfer with minimal environmental footprint. Hydraulic elevators involve fluid use that can pose spill risks, whereas siphons utilize gravity-based principles that avoid chemical use and waste discharge. Implementing siphon systems in water management enhances resource efficiency and reduces reliance on mechanized pumps, aligning with eco-friendly and sustainable practices.

Pros and Cons of Elevators

Elevators offer efficient vertical transportation, capable of moving large numbers of passengers quickly and safely between floors, making them ideal for high-rise buildings. Their advantages include accessibility for people with mobility challenges and integration with smart building systems, while drawbacks encompass high installation and maintenance costs as well as energy consumption. Unlike siphons, which rely on fluid dynamics and require specific conditions to function, elevators provide controlled, reliable movement regardless of building height or external factors.

Pros and Cons of Siphons

Siphons offer the advantage of transferring liquids over obstacles without requiring a pump or external power, making them energy-efficient and cost-effective for irrigation, drainage, and aquarium systems. However, siphons can be prone to air leaks and require proper priming to maintain flow, which may limit their reliability and ease of use compared to elevators or pumps. Their dependence on gravity and initial suction also restricts their functionality to specific elevation differences and fluid types.

Choosing the Right System for Your Needs

Choosing between an elevator and a siphon depends on factors such as application type, efficiency, and maintenance requirements. Elevators excel in vertical transport with precise control and are ideal for building construction and material handling, while siphons leverage gravitational flow for fluid transfer over barriers without mechanical parts. Evaluate load capacity, energy consumption, and installation environment to select the optimal system tailored to your operational demands.

Elevator Infographic

libterm.com

libterm.com